Contents

- “Armor” for transport

- Alloy for new cooling systems

- Composite with the possibility of regeneration

- Fiber for clothing with a built-in neural network

- Endlessly recyclable plastic

- “Cloth” for the cloak of the invisible man

- Film for glasses instead of night vision devices

- Metal vs grinder and drill

- A sound deadener that can keep planes quiet

- Gold with the properties of plastic

- Where material science is heading

Some things, like memory fibers or bulletproof film, seem impossible. However, scientists are working on them and quite successfully. We talk about ten materials of the future and trends in material science

Material science is the science that studies materials. Scientists are looking for ways to improve existing materials or develop new ones, explore their properties and structure. Discoveries often amaze the imagination of even the most dedicated fans of science fiction.

“Armor” for transport

Scientists from Perm and Tomsk Polytechnic Universities have jointly developed a heavy-duty cast glass-ceramic material. It is based on oxides of silicon, magnesium, aluminum, titanium and manganese. When exploded, the new material distributes energy over its entire area, so it is more resistant to external influences and high temperatures. Similar materials, on the other hand, take a hit at one point and are destroyed because of this. Scientists claim that products made of cast glass-ceramic material will last 15 times longer than those made of metal.

The Russian invention has analogues, but they contain harmful and expensive substances to produce. For the manufacture of cast glass-ceramic material, scarce, expensive and toxic substances are not required. It can be used to make impact-resistant cases for cars and railway transport, as well as paving slabs, curbs, fountains, decorations for facades.

Alloy for new cooling systems

Scientists from the National Research Technological University “MISiS” in collaboration with LG Electronics have created new high-thermal-conductive magnesium alloys. Their main advantage is resistance to high temperatures, so the materials are planned to be used in cooling systems. The problem with analogues is that they quickly heat up and even catch fire in the sun. For example, in 2018, a fire broke out in a workshop at a BMW plant in Germany, where a large number of magnesium alloy parts were located.

The new material extends the life of household appliances, electric vehicles. In the USA, EU countries, Korea and China, scientists have patented not only the alloy, but also a radiator based on it.

Ivan Kruglov, Head of the Computer Materials Design Laboratory at MIPT:

“High thermally conductive magnesium alloys are one of the successful examples when a computer first investigated the properties of Mg-Zn-Si-Ca compounds, and then scientists implemented the most promising of them. Without the help of software, these materials would have taken several times longer to create.”

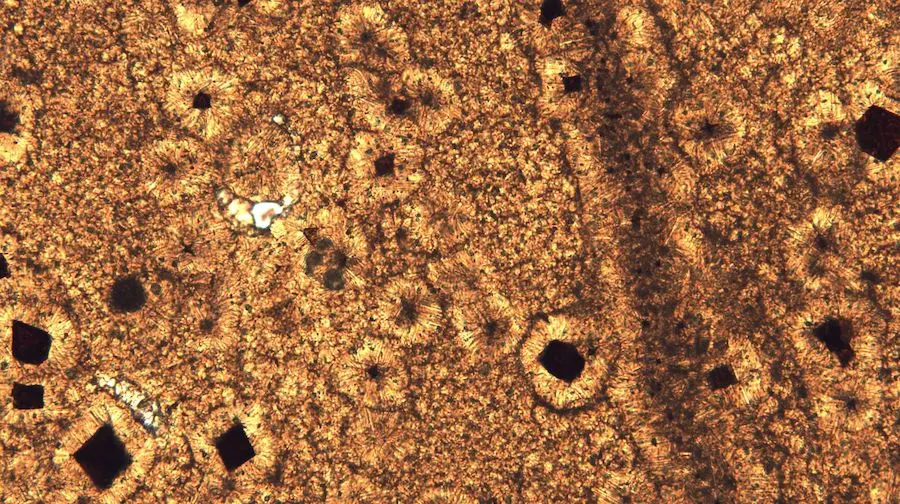

Composite with the possibility of regeneration

The Research Institute of Space and Aviation Materials (NIIKAM) in the city of Pereslavl-Zalessky has developed a new composite material called aristides. It is ten times lighter than industrial aluminum and stronger than titanium. The thin 3mm plate withstands point-blank range from a medium caliber pistol. In this case, the damage from the bullet remains only on the surface of the material. Aristide has the property of regeneration and independently restores small damage. It is also heat resistant and can withstand temperatures up to 1300℃. For comparison: a fire in a fireplace flares up to a maximum of 1200 ℃.

The developers claim that aristide can replace composite materials that are used in the manufacture of parts for spacecraft, satellites, and aircraft. It can also be used in the automotive industry, construction, the production of prostheses and pacemakers.

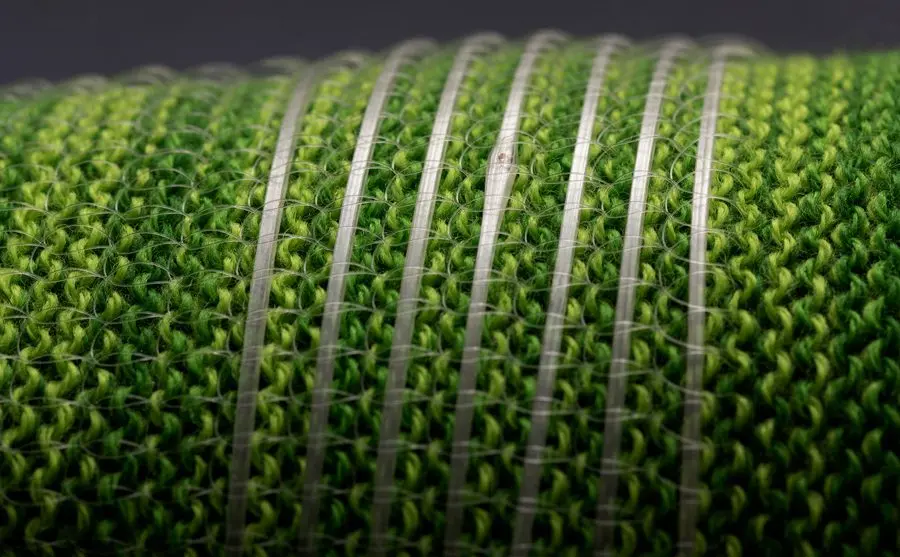

Fiber for clothing with a built-in neural network

The Massachusetts Institute of Technology (USA) has developed the world’s first digital fiber – a thin and flexible thread that is sewn into any fabric. Thanks to the built-in neural network, the development is able to recognize, store and analyze information. For example, to determine what kind of physical activity a person is engaged in. This was proved during the experiment: a man sat, walked and ran in clothes with digital fiber, and at this time the sensors analyzed changes in body temperature and transmitted data to a computer. The development was able to determine with an accuracy of 96% what action a person performs. The principle of operation of the novelty can be compared with a smart watch that knows that you have started moving, how fast you are walking and how many steps you have taken.

The scientists plan to make things with digital fiber for mass consumption. Such clothes are not felt on the body, and they can be washed up to ten times. While a person is wearing the product, it measures the pulse, temperature. The developers claim that in the future, the technology can store music in clothes, because they have already been able to record 30-second audio weighing 0,48 megabytes on fiber.

Endlessly recyclable plastic

According to a study by the US Environmental Protection Agency, only 12% of plastics in America are recycled more than once. Most of its species are not reusable. In 2019, American scientists created a new plastic, polydiketoenamine (PDK), that can be recycled endlessly. MPC without harm to quality is “disassembled” at the molecular level and assembled into another form with a new texture or color. Scientists even designed a computer model of equipment for the production and processing of material. Based on it, you can make a real installation.

Polydiketoenamine can replace plastic used in the manufacture of household items, machinery, construction and medical products. According to the plans of scientists, the new material will help clean up the environment from garbage.

“Cloth” for the cloak of the invisible man

Canadian company HyperStealth Biotechnology has developed quantum invisibility technology. Through the new material, as through glass, you can see almost everything that is behind it. However, the rays of light, falling into microscopic lenses, are scattered, and everything that is at a certain distance behind the material – be it people or objects, becomes indistinguishable. The material is similar to thin plastic, but the company has not yet disclosed its exact characteristics.

The developers have patented 13 types of material of various shapes and purposes. Some can hide a person, others – buildings, others – transport, space and military equipment, ships. Based on the new material, it will be possible to create camouflage for the military and police, and in the future for mass consumption.

Film for glasses instead of night vision devices

Scientists at the Australian National University have developed an ultra-thin film that is made up of microscopic crystals and makes infrared radiation visible to the human eye. The material is inexpensive and easy to manufacture.

It is planned that the development will be used in the security services and the armed forces. Now they use bulky night vision devices that can cause neck pain. The new ultra-thin film is attached to regular glasses – it is more comfortable and makes it easier to work in the dark. In the future, the mass use of new items is possible: for example, the film is useful for driving a car in poorly lit places.

Metal vs grinder and drill

German physicists have created the Proteus material, which cannot be cut. It is stronger than steel and seven times lighter than steel. When developing, scientists were inspired by nature – the shell of sea snails and the skin of grapefruits. It turned out that their structure consists of interweaving of soft and dense elements. The physicists repeated this principle in their design and got a material that looks like jelly and is filled with many hard ceramic pieces.

Scientists suggest that the invention will be used for the manufacture of safes and protective equipment against edged weapons and for working with cutting tools. After all, if you try to cut Proteus with a grinder or drill, it will destroy the disk and drill. This happens because the material causes lateral vibrations inside the cutting edges. In the experiment, a block 4 cm thick in a minute made the grinder disk unusable.

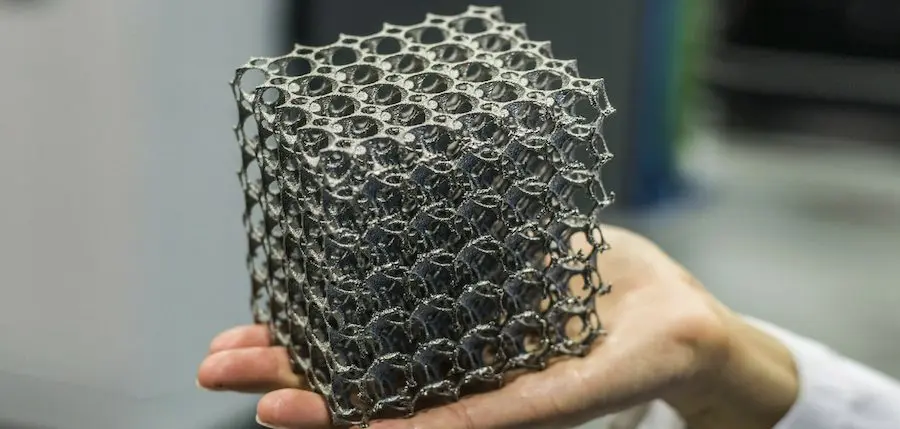

A sound deadener that can keep planes quiet

The British University of Bath has developed the lightest sound-absorbing material. It is made from liquid graphene oxide and alcohol. The invention is similar to a honeycomb, only inside is not honey, but a dense matter with many air bubbles. Professor Michele Meo, who leads the development team, explains: “The method of obtaining the material can be compared to beating egg whites to create meringues. That is, the sound insulator is strong, but contains a lot of air.

The development is planned to be used in aircraft engineering: it is very light and can reduce the noise level of aircraft engines. Airliners could become almost as quiet as new cars, scientists say. So far, the material does not dissipate heat well, so there is a risk of overheating. Scientists are doing more research to solve this problem. Also, experts want to find other useful properties. For example, fire resistance or the ability to protect against electromagnetic waves.

Gold with the properties of plastic

Switzerland has developed gold, the density of which is ten times less than usual: 1,7 g/cm3 in relation to 15 g/cm3. The properties of the material resemble plastic, but the chemical composition is the same as that of natural metal. The product from it cannot be broken with bare hands or broken, even if dropped from a great height. “Plastic” gold contains many air pockets that are invisible to the eye, which is why it is so light.

The invention will help to reduce the weight of the watch case, it is also supposed to be used in the production of jewelry, electronics, nuclear and chemical industries. At the request of the customer, the modified gold can be changed in density, softness and color.

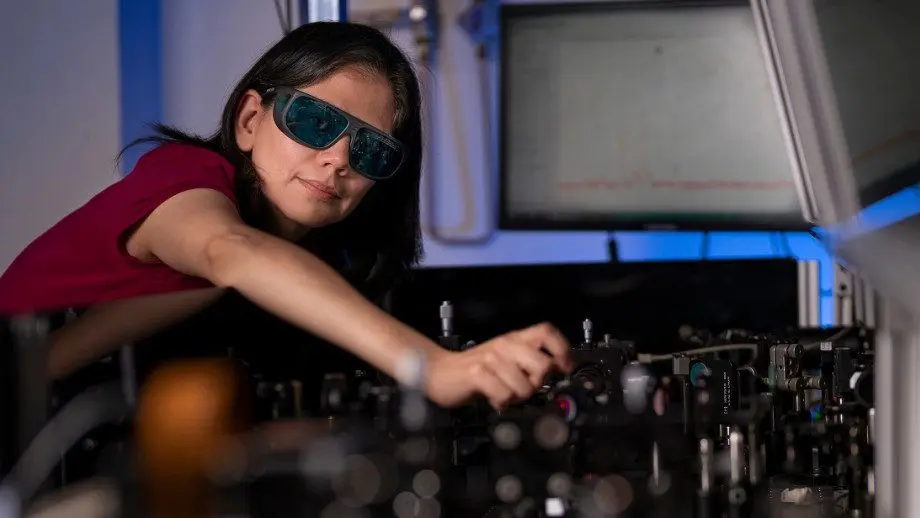

Where material science is heading

Ivan Kruglov, Head of the Computer Materials Design Laboratory at MIPT:

“Before, scientists had to use trial and error to develop new materials and study their properties. At the same time, everything was limited by the professionalism of a specialist. That is, if he does not know about the resistance of copper wires to vibrations, he will not understand that they can be used in transport. This approach is called experimental.

In 2021, another approach is gaining popularity – computer methods. This means that special programs look for new materials and predict, for example, how an alloy will behave at high temperatures or how strong a new type of plastic will be. Most often, this method is used to search for superconductors (they lose electrical resistance at low temperatures) and thermoelectrics (substances that form an electric current at a temperature difference). Thanks to technology, it has been possible to accelerate the process of searching for various materials, which means that faster development is expected in other industrial and scientific fields.

In the Russian field of material science, emphasis is placed on the development of:

- new superhard materials;

- steel compositions with improved properties;

- polymer composite substances, that is, those that consist of several components;

- structural and functional materials – these are machine parts, structural elements and other products that carry a power load.

In 2021, the NTI Center “Digital Materials Science: New Materials and Substances” was specially created in this area. One of the promising developments is teaching computers to find unique compounds for industry. This is possible thanks to existing databases of substances: the program analyzes them and offers its own options with improved properties.”