Brewing beer is one of the most complex technological processes in the food industry. To obtain a high-quality drink, brewers need to take into account many nuances and carefully select the ingredients. Next, we will look at the important steps in the classic brewing technology that most modern breweries use.

First, let’s find out what beer is made of. In the traditional recipe, only four ingredients are allowed:

Malt – a product obtained by sprouting cereals. Malted barley is used to make beer, a process that promotes grain germination. After soaking, barley swells, chemical reactions begin inside the grains, splitting the starch into the malt sugar needed for fermentation.

Water. In brewing, water is distinguished by its composition and concentration of salts. For some types of beer, “hard water” (high in salt content) is better, such as Munich. There are varieties made exclusively on water with a low salt content, this is Pilsner beer. Modern technologies make it possible to regulate the concentration of salts in water with a very high degree of accuracy, which simplifies production.

Hop. Gives beer a characteristic bitter taste, fragrant aroma and is responsible for foaming. It is impossible to replace hops in beer production without quality loss. This is a unique plant, which includes more than 200 substances responsible for taste. Interestingly, only the cones of female hop plants are suitable for beer.

Yeast. Modern factories use special brewer’s yeast of the Saccharomycetes family, which are not found in nature, but are artificially bred specifically for brewing. Depending on the fermentation technology, two types of yeast are involved in the production of beer:

- top-fermented (Saccharomycetaceae cerevisiae) – suitable for beers such as porter, ale and stout;

- bottom fermentation (Saccharomycetaceae carlsbergensis) – used in the manufacture of lager and Central European beer.

The difference between these types of brewer’s yeast is that at the final stage, the top-fermenting yeast gathers on the surface (floats), and the bottom-fermenting yeast – at the bottom of the wort. This significantly affects the taste.

Stages of beer production

1. Preparation of wort. First, barley malt is crushed, but the grains should not turn into a homogeneous mass. In the composition of the wort, large and small grains are required. This is called malt grinding. In different types of beer, the ratio of large and small particles is different.

The malt mill is then mixed with water. This process is called “mashing” and the resulting mixture is called mash. When water is added, barley enzymes begin to break down the starch into malt sugar. To speed up fermentation, brewers heat the mash to 76°C.

Next, the finished wort is filtered. The boiled mash is poured from the boiler into a special sieve, closed from below. The mashed malt stays in this state for some time, until solid particles, called grains, settle at the bottom. When the sieve is opened, pure liquid wort begins to seep through it and a layer of grains, which is collected in a special boiler for subsequent boiling.

2. Boil the wort. The wort obtained in the previous step is heated, brought to a boil and hops are added. The number of cones depends on the type of beer and the preferences of the master. Each recipe uses a different amount of hops.

Boiling the wort takes 2-3 hours. During this process, all microorganisms die and enzymes are destroyed, so further chemical reactions are impossible. Brewers achieve a predetermined gravity of the initial wort, which is referred to as beer gravity on the label of the finished product.

Next, the boiled wort is filtered from hop residues and allowed to settle. At the bottom, the smallest particles fall out that could not be filtered out at the previous stage. Also, some plants speed up the removal of unwanted residues by centrifuge.

3. Fermentation. Pure wort enters through pipes to the bottom of the fermentation tanks, called cylindroconical tanks. After the liquid has cooled to the desired temperature, yeast is added to the vat. For top-fermented beer, before adding yeast, the wort is cooled to 18-22°C, for bottom-fermented beer – to 5-10°C.

A day after the laying of the yeast, a thick layer of foam appears on the surface of the fermentation tank. This means that the yeast has successfully started converting sugar into carbon dioxide and alcohol. During fermentation, a lot of heat is released, so the wort needs constant cooling, the temperature must be stable.

During the fermentation stage, brewers monitor the concentration of carbon dioxide in the vats. When the maximum allowable level is reached, the gas is removed through special pipes. Fermentation stops after the yeast has converted all the sugar into alcohol.

4. Ripening. At the previous stages, a young unfiltered beer was obtained, requiring further maturation (does not apply to wheat varieties). For ripening, large stainless steel tanks are used, and the process itself lasts from several weeks to four months.

During ripening, it is necessary to maintain a stable temperature and pressure in the containers, fluctuations are unacceptable. At modern enterprises, the technological process is controlled by special equipment that can automatically change temperature and pressure.

5. Filtration. After maturation, the beer goes through another filtration with two different filters designed to remove large and small particles. After that, the foamy drink becomes absolutely transparent and ready for bottling.

6. Bottling. At the final stage of production, beer is poured into containers of different types. Before bottling bottles, kegs or kegs, all containers are washed, then the air that has got inside is removed. Beer is a perishable alcoholic beverage that requires sterile conditions. Without sterility, the shelf life of the finished product is only a couple of days. When pouring into glass containers, the bottles are pre-pasteurized – slowly heated to a temperature of 65 ° C, which significantly extends the shelf life of beer.

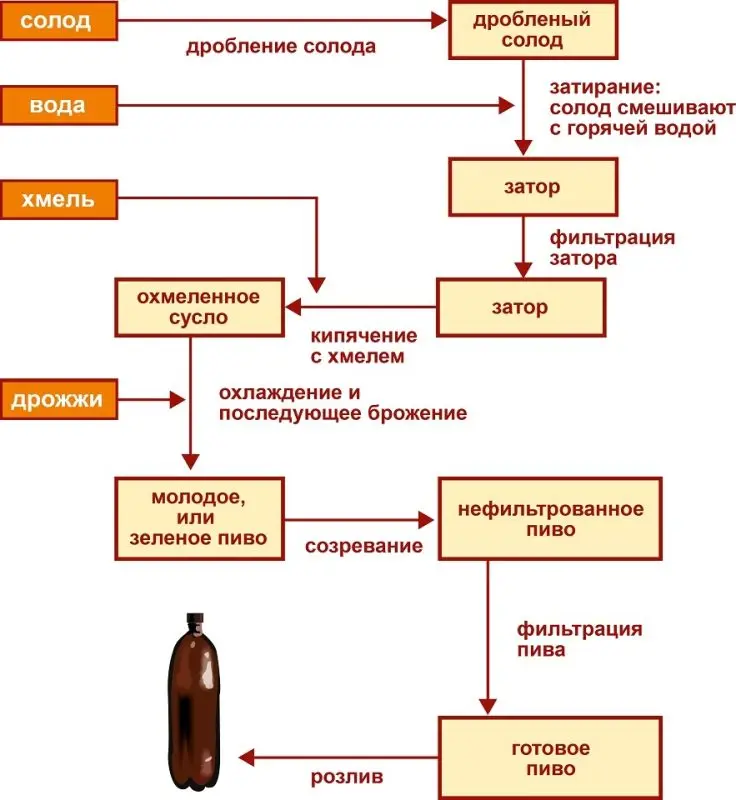

To systematize all the information, I propose to look at the following diagram illustrating the sequence of stages.