Contents

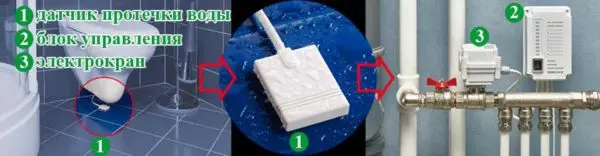

Leaving the apartment for a long time, we close the hot and cold water taps, protecting ourselves from the flood in our absence. But leaving every day for work, we do not do this. And the opportunity to flood the house and neighbors still remains. The best way out in this situation will help to install a leak protection system Hydrolock (Gidrolock).

The principle of operation and the composition of the system

Producer – LLC “Gidroresurs”. The production of the system has been established in Russia, Mytishchi, Moscow Region, using both domestic and imported components.

Composition of the systemComposition of the Hydrolock system:

- Water sensors. There are wired and wireless.

- Ball valves with servo drives of various sections.

- Signal processing controller.

There are several versions of the system, which differ in a more complete set of parts and advanced functionality. It is possible to assemble the anti-leak system from components.

When water gets on the sensor, the signal lamp lights up and the controller emits an audible signal. This double informing is done for reliability, which is confirmed by the owners of the system.

Features of work and differences

As already mentioned, the gidrolock system has differences in configuration, quality of components and a set of functions. Let’s consider in more detail.

The reasons for the good reviews about the Hydrolock system are high-quality components and reliable operation. Reliable ball valves made of brass and Bugatti stainless steel, powerful servo drives with three operating modes – nominal, reinforced and maximum.

Design features

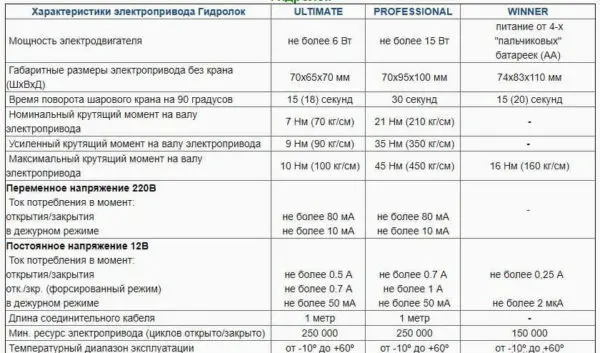

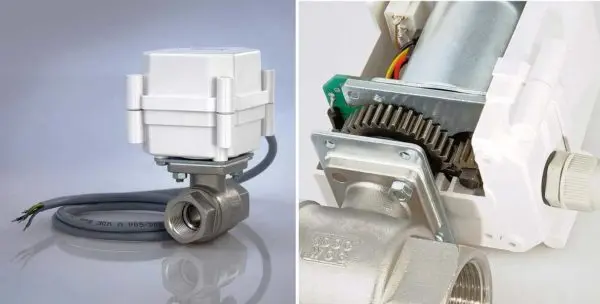

Different Ultimate, Professional, Winner systems use servo drives with different torque on the shaft – 100, 450 and 160 kg/cm. This is enough to close even a jammed tap.

- In electric drives, only a metal gearbox is used.

- The drive rotates only in one direction, and this increases the torque of the gearbox and reduces the load on it.

- The controller responds to the presence of a gap. For safety, there are no electrical contacts in the crane.

- The motor is brushless, which guarantees a long service life.

- The fastening is simple and, if necessary, can be quickly removed and accessed to the faucet valve.

- The water sensor is a small circuit that eliminates false positives.

Remove the drive can manually close the water

Remove the drive can manually close the water - The water presence sensor in the Hydrolock leakage protection system is not just two contacts. This is a small circuit that virtually eliminates false positives. To protect against oxidation, the sensor contacts are gold-plated.

Some design solutions to prevent leaks from Hydrolock distinguish them favorably from competitors “Akvastor” and “Neptun”.

Functional Testing

The Gidrolock system should operate extremely rarely and is in standby mode most of the time. To keep the equipment working, it is necessary to test it. The test is carried out automatically. To prevent deposits in the tap from jamming, once a week they are forcibly closed and opened. If the valve fails to close, the alarm is activated.

Reliability and safety

Everything is provided for security in the system:

- Power supply of all elements with voltage – 12 V from the converter.

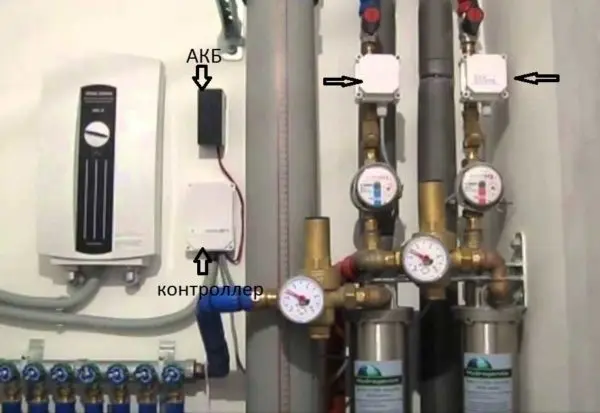

- Availability of redundant power supply. In the absence of mains voltage, power is supplied from the battery.

Power is supplied from the mains 220 V and battery - The case is hermetic with degree of protection IP67.

- The water sensors are low voltage powered and soldered to reduce the possibility of failure.

- Cranes with the possibility of grounding.

- In standby mode, the taps are de-energized. In the event of a leak, 12 volts is supplied for the time required to close.

- In wireless devices, sensors have batteries.

As you can see, the Hydrolock control system is well thought out and quite safe. Although there are shortcomings, but we’ll talk about them later.

Additional features

There are two more options in the Hydrolock leak protection system:

- Forced shutdown of water by pressing one button. It makes sense to install it near the door. Allows you to quickly shut off the flow if necessary. For example, leaving home for a long time.

- Forced retention of water supply for 30. For example, a sensor under the bath while taking a shower can give a signal to operate. Turning on the option, you can finish things, and then restore the system.

Hydroloc control unit has the ability to connect a large number of equipment:

- 20 electric drives.

- Up to 200 wired or 100 wireless sensors.

- The possibility of GSM notification, that is, a signal about an accident will come to your phone.

- Installing a radio module allows you to control the system with a remote control and install wireless sensors.

- Separate light signaling for up to 8 control zones. No need to look for exactly where it flows.

When installing a water leakage monitoring system in a private house, connecting a relay to the controller can turn off any device. For example, the system will not only close the tap, but also turn off the power to the pump.

SENSORS

As already noted, the Hydrolock leakage protection, depending on the option, is equipped with two types of sensors in the amount – up to 200 wired and up to 100 wireless. The sensors are 2 contacts (there are three in the WSU), upon contact, on which water forms a signal. The signal is sent to the control unit, which gives the command to turn off the water. It takes 15–20 seconds from the moment water hits the contacts until the servos start working.

The sensors are raised 1mm from the surface to prevent false alarms.

Wired

The sensors are equipped with a cable with a length of 3 to 5 meters, if it is not enough, then it can be extended up to 100 meters. Recommended cables FTP 2x2x0,35 and ShTLP 4.

Sensors included in the kit:

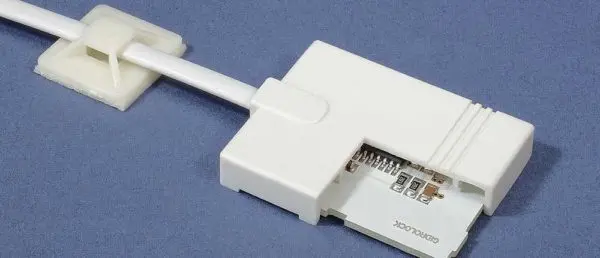

- WSP – passive type sensor in a plastic case with dimensions of 35 * 47 * 8 mm. Cord length 3, 4, 5 m. Supplied with Enerdgy, Universal, Premium kits.

- WPS+ – passive with line break control. For Hydrolock Premium systems.

External and internal view of the sensor - SWU (WSU)is an active sensor. Opportunity to work in the “smart home” system. Enclosure IP 67, cable length 3 m, extendable up to 100 meters.

Wireless devices

Wired sensors are more reliable, since wire breaks are extremely rare. Radio sensors may be affected by interference that cannot be foreseen. To prevent such a case from leading to a false alarm, the system can send SMS (if there is a GSM alert), but the water does not close.

- Radio sensor – Spider. Used to expand territory. Connection to the control unit is wireless, but up to 20 wired WSP sensors are connected to the spider in parallel. “Spider” monitors signals from connected devices and in case of water leakage transmits a signal to the controller. Power supply 3 volts, dimensions 45*70*8 mm.

Spider expansion module - WSR. Sensor in the form of a small cylinder in five colors. Works alone or with connected WPS sensors. Powered by CR2450 battery. The cost is $30.

WSR wireless sensors match surface color

When installing them, you need to carry out the procedure of the so-called acquaintance with the control unit and then decompose it into the necessary places.

Servo drives and ball valves

In the documentation, this design is called ball electric cranes (SEC). The valves are full bore, that is, they do not affect the flow and do not create water hammer.

In three types of Hydrolock systems: Ultimate, Professional and Winner, they differ in parameters. Their characteristics are shown in the table:

The large torque makes it possible to move the boiled taps, which is why the gearboxes are made of metal. The long closing time of the taps is not so important, it is more important to close the tap and eliminate the leak.

Disadvantages of Hydrolock protection

The Hydrolock water leak monitoring system is well thought out. However, every system has its drawbacks. In this case, they are non-critical and with proper care they can be avoided, these are:

- The system cannot be mounted on a DIN rail.

- If the battery fails, the system does not work.

- The batteries in the sensors are soldered.

After the system is triggered, Hydrolock will not restore operation on its own, even with dried contacts. You need to turn it off and on.

Remove the drive can manually close the water

Remove the drive can manually close the water