Contents

In one wise parable it is said that if you do not sharpen the tool, then you will have to put more effort into doing the job. This applies to many industries. But there is one that takes a lot of time and effort – logging. Those who use stove heating or solid fuel boilers know how tiring it is. To alleviate the situation, many decided to purchase a hydraulic wood splitter. This device is ready to do almost all the work for you. There are a large number of models on sale, and you can also assemble it yourself. How to make the right choice when buying and assembly schemes will be discussed in this article.

Wood splitter device

Those who already have a wood splitter in their arsenal were able to verify its effectiveness. Simply put, the hydraulic wood splitter is assembled on three main nodes:

- the bed of the woodcutter;

- engine;

- hydraulic unit;

- cleaver.

According to the type of fuel used for the engines of a hydraulic wood splitter, electric and gasoline units are distinguished. Electric – most often used in everyday life. The power of such products is within 3 kW. Their advantage is the absence of harmful emissions and low sound pressure during operation. It also does not require specific maintenance. If desired, an electric hydraulic wood splitter can be used on the road, but you will have to get a generator with sufficient power. Professional models of hydraulic wood splitters are equipped with gasoline engines. They are more mobile, so it is easy to take them with you directly to the forest or forest belt for harvesting.

The bed is the basis of the entire design of the hydraulic wood splitter. It is made of steel with sufficient thickness. Often wheels are attached to it for ease of movement. It also has a hydraulic unit. It is a small device that converts rotational movements into translational ones. Its part is a gearbox and an oil pump. It is designed to reduce the number of revolutions to the required. The increased force is transferred to the hydraulic wood splitter. This is a metal plate with a conical tip, which carries out the chopping of logs.

Varieties of wood splitters

In addition to the difference in engines, wood splitters also have several ways to implement the design of the bed. Among them are:

- horizontal;

- vertical;

- variable.

The horizontal bed of the wood splitter is the most used. Most often, in such a wood splitter, it is not the cleaver that moves towards the log, but, on the contrary, the feed mechanism pushes the workpiece until it is completely split. Hydraulic wood splitters with a vertical bed are somewhat more convenient than horizontal ones, because you don’t have to raise the workpiece to some height, but simply put it on a stand. The knife here moves from top to bottom. This type of wood splitter requires more scrupulous observance of safety measures. Variable bed wood splitters are the most versatile. They have the smallest restrictions on the length and width of the log, since the workpiece can be processed in several planes at once. For home use, such a unit is not suitable, because it is more often designed for industrial use.

What to look for when choosing

Hydraulic wood splitters are safer and more reliable than their direct drive counterparts. The difference lies in the way they react to unyielding logs. If in a direct drive device, when the cleaver is jammed, the engine continues to rotate, then this will inevitably lead to failure of not only the windings, but also the gearbox. In hydraulic devices, the situation is different. As soon as the force exceeds the allowable, it stops without harming the central unit. Before you buy a device, you should think for what purpose it will be used. It makes no sense to overpay for an industrial design if it will be used for harvesting at home. When buying, pay attention to:

- engine type and power;

- frame material;

- frame metal thickness;

- quality of welds;

- maximum force mass;

- parameters of processed logs;

- cylinder stroke length;

- the length of the knife of the hydraulic wood splitter;

- rod movement speed.

The performance will directly depend on the engine power of the hydraulic wood splitter and its power source. If you expect good performance, then it makes no sense to buy a device with a power of less than 2 kW. Pay attention to the assembly of the motor itself and ask the seller what the windings are made of. Copper is considered a good quality. Before purchasing, carefully inspect the frame. It is better if it is made of a channel or a corner with a metal thickness of at least 3 mm. Pay attention to the quality of the welds, if any. They should not have chips or cracks. Otherwise, it may result in injury.

The more pressure the wood splitter hydraulic system can exert, the greater the force will be, which means that hard woods and those with a large number of knots will not create any special problems. It is worth taking a device in which there is a good power reserve, and the height of the knife is also adjustable. It will give you the opportunity not to limit yourself in the choice, and also not to bother with finer cutting of trunks. The speed of the rod movement is often referred to as the cycle time. The smaller it is in time, the faster it will be possible to cope with a mountain of firewood.

Self assembly

The purchase of a ready-made hydraulic wood splitter will cost the future owner in the amount of 15 thousand rubles. Not everyone is ready to shell out such an amount for a device that will be needed once a year. Therefore, if desired, it can be assembled with your own hands according to ready-made drawings, while a hydraulic wood splitter will cost half as much. But this will require the skill of working with power tools and a welding machine. For the whole process you will need:

- Bulgarian;

- welding machine;

- roulette;

- high torque drill.

The first step is to assemble a frame for a hydraulic wood splitter. As a basis for a hydraulic wood splitter, an I-beam channel with a side width of 40 mm is suitable. The length of the hydraulic log splitter can be adjusted according to your needs. With the help of a welding machine, a wheel pair is welded to the channel. For this, a metal pipe is used, in which an axle is placed for attaching the wheels. It is held by spacers from a square with a size of 20 × 10 mm. A better design of a hydraulic wood splitter can be seen in the photo. All seams are well welded to withstand the load.

A hydraulic wood splitter will not do without a special cylinder that will act as a pusher. It can be purchased at disassembly from an old tractor. Suitable is the one used in the design of the bucket or for the trailer system.

To fix it on the frame of the hydraulic wood splitter, two squares are cut out of sheet metal. Their height must be 8 cm greater than the height of the hydraulic cylinder. A hole is drilled in the center of each workpiece. Its diameter must match the one in the cylinder body. The slats are welded into place and the cylinder is fixed with a sleeve. More details can be seen in the photo.

The module of the hydraulic wood splitter, which will shift the log, is made according to a similar pattern, but guides are made in the lower bar so that it moves only along the bed of the hydraulic wood splitter and does not skew with great effort. Pay attention to this node in the photo.

As an option, the design of the hydraulic log splitter will use an electric motor with a power of 7,5 kW for three phases. In the following photos you can see the junction to the pump, and the way the pump itself is attached to the frame.

The hydraulic converter can be used from a mini-tractor, which was originally designed for the use of a heavy hitch. High pressure hoses are used to connect all components to each other.

In order to have enough oil in the system, you need a tank. You can use it ready-made or make it yourself, as in this case. The volume of the container is 66 liters. The dimensions of its walls are 60 × 50 × 22 cm. The seams are well welded.

A ½” hole is made at the top for an automatic relief valve, on the side for filling oil, and from the bottom there is an outlet to the hydraulic system with a diameter of ½”, where a crane is mounted. After that, it can be installed in a log splitter and connected to a hydraulic pump.

Further, the wiring of the electrical part is done through the starter, since the motor is designed for 3 phases. All wires are selected according to the required section.

As a cleaver, two perpendicularly welded and sharpened plates are used. Good metal in the shares from the tractor hitch. This product will last as long as possible. Alternatively, you can make 8 knives so that the grinding is large. The result is in the photo below.

In order to prevent the log from rolling off the wood splitter, additional holders can be made on the sides of the bed. They are welded on the corners at an angle. They can be seen in the photo with a general view of the finished version.

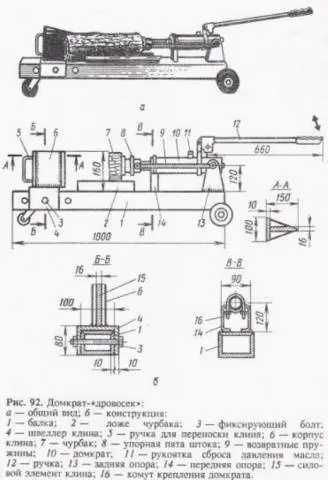

The assembly diagram is provided as a general guide. In each case, you can use those components that are easiest to find in your area. Instead of an electric motor through a gearbox, it is easy to use a gasoline one. The automatic wood feed unit can be omitted to simplify the overall design and reduce costs. It is also possible to assemble a manual hydraulic wood splitter. For this, a conventional jack for 10 tons is suitable. A detailed diagram will be shown below.

The video shows the operation of a wood splitter with an engine that was made according to the instructions. Such a device allows you to save time, which you can then spend with your family and loved ones.

Conclusion

The main thing is to understand the principle of its operation when assembling a hydraulic wood splitter. With the right approach, what might seem unnecessary will work as a future stand or part for a wood splitter. The main thing is to connect fantasy and logical thinking.