Contents

The motor in the washing machine performs its main function – rotation. And the bearings serve in the engine to reduce friction. Their service life is significantly reduced if not periodically lubricated.

To check the electric motor or replace defective parts, you need to remove and disassemble the electric motor. The bearings in it are located on the armature or rotor shaft.

Electric motor disassembly rules

The washing machine can be equipped with a collector or asynchronous motor. They are disassembled in different ways, but still, there are general rules that should be followed when disassembling:

- Before disassembling the motor, unplug the washing machine and remove the motor by disconnecting all wires.

- If capacitors are provided in the motor control circuit, it is worth discharging their terminals.

- Disassembly eliminates shocks and distortions and goes in a strict sequence – stage by stage.

- Disassembly begins after the mechanism that rotates the engine is disconnected – in our case, it is the belt that rotates the pulley (or the drum – in the direct drive CMA).

- During operation, proceed carefully so as not to damage the shaft, winding, manifold or brushes.

How to check bearings

Replacing bearings in a washing machine engine begins with checking them. If you do not notice wear and tear in time (noise in the operation of the MCA), then in the most severe case the result will be as follows: during rotation, moving and immovable parts of the engine will begin to touch, which will lead to breakdown of the entire engine.

The check goes like this:

- Place the motor on a firm, level surface.

- Hold the engine with one hand and rotate the shaft with the other.

- If everything is normal, then the rotor will spin smoothly, without snagging.

- If the bearings have worn out, then you will hear scratching sounds or notice that there is an imbalance when the rotor rotates.

Backlash: how to check

Axial or radial play is absolutely normal and is typical even for new parts. It is only important that the backlash is not too great.

Check radial play:

- Place the motor on a level and hard surface.

- Grasp the shaft with your hand and swing it.

- Only slight deviation is permissible.

- The displacement ratio is directly proportional to the size of the motor. In a household washing machine engine, these displacements can be subtle.

Check the axial play:

- Grasp the shaft and pull or push the rotor away from you.

- A deviation in the CM engine of more than 0,3 cm already indicates a problem.

If, disassembling the motor, you find traces of friction between the rotor and the stator, then this already says that the engine needs repair, or rather, a change of bearings. If the rotor is worn out, then this element must be replaced as well.

Dismantling stages

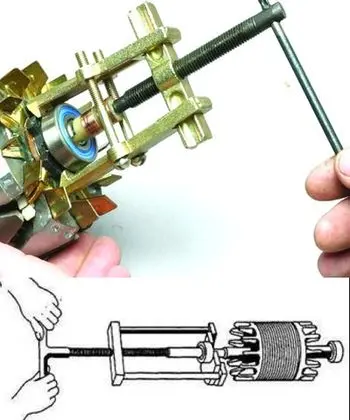

Remove the motor bearings before replacing them. To carry out this operation, you need pullers. It is important to keep in mind that they differ in size and design, so if you are not sure, take an engine to the store to find the right puller.

In principle, you can estimate and buy a puller “by eye”:

- For small shafts, a mechanism with removable gripper bars is suitable.

- For a larger shaft, it is worth taking a massive puller with 3-4 legs that grip the bearing.

If you are using a puller, you will have to make an effort to rotate it. If it’s too heavy, grab a piece of pipe to lengthen the arm. For easier removal, you can lubricate the shaft with machine oil or WD-40 grease.

We put on a new bearing

After removing the parts from the washing machine motor, you can start installing new ones. The new item must be 100% identical to the part you are changing.

During installation, make sure that dirt does not penetrate into the bearing. Also inspect even a new element for integrity. The marriage has not been canceled – there may be chips or metal corrosion inside.

Installation rules:

- Install the part using a small diameter metal stud.

- It is recommended to lubricate the part with grease before installation.

- Make sure that there are no distortions, so hit clearly in the center of the hairpin, placing it in different places.

- To speed up the process, you can dip the bearing in boiling oil for 5-10 minutes. Pull out the part using a hook or pliers. Do not work with unprotected hands!

Bearing grease

The performance of the CMA will depend on what kind of lubrication will be used when installing the bearing. The lubricant must be chosen thick – consistent.

If the engine speed does not exceed 3 thousand in 1 minute, you can use “Litol 24” or “Tsiatim 201”. If the engine is running at high speeds, choose a second grease labeled 202.

More than half of the bearing chamber needs to be filled with grease. For high-speed ones, one third will be enough – if you put more, excess grease will still be squeezed out during rotations.

Now you know how to change the bearings of an electric motor, if your washing machine requires it.