Contents

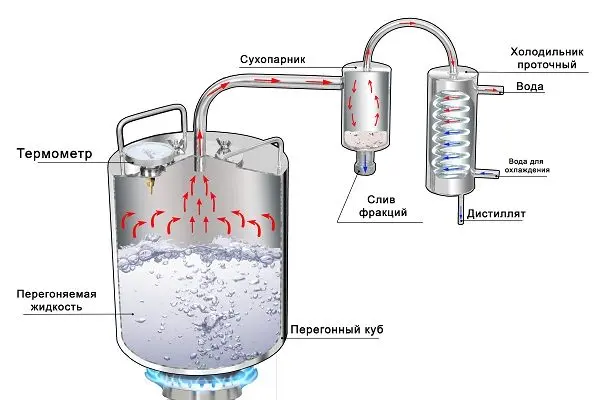

Although there are many home distillers of different price categories on the market, experienced moonshiners prefer to make equipment on their own or place an order with trusted craftsmen according to their own drawings and diagrams.

The advantage of this approach is not only cost savings. Often, a self-made moonshine still is more reliable and practical than most store models with incomprehensible elements that contradict the laws of physics, installed only to attract a buyer and raise the price. Next, we will consider the classic design of a moonshine still (distiller), which has no equal in simplicity and efficiency.

Connecting elements

Intermediates play an important role. With the wrong choice of pipes or sealant, moonshine turns out to be cloudy, with a nasty aftertaste, foul-smelling and even dangerous to health. Therefore, we will begin our consideration of the design with the connecting elements.

It is not necessary to “tightly” weld all the tubes together, this simplifies the assembly and disassembly of the device, but causes a lot of problems during cleaning.

As a transport system, metal tubes made of stainless steel, aluminum or copper are most often used, as well as food or medical silicone hoses inert to alcohol. In terms of economy, safety, ease of maintenance and operation, food grade stainless steel tubes are the best option.

It is important to be able to distinguish silicone hoses from those made of PVC (polyvinyl chloride saturates alcohol with poisonous substances when in contact with hot steam). PVC burns with a lot of smoke and an unpleasant odor. Silicone does not smoke when burned, leaving a subtle smell and light ash. Silicone tubing is much softer to the touch than PVC and costs about twice as much.

For branching turns, transition from one diameter to another and connecting different parts in metal pipelines, fittings and fittings are used, which can be found in plumbing stores or in construction markets. Fittings made of brass, bronze and stainless steel (the best option) for heating systems that can withstand high temperature and pressure are suitable for the manufacture of a moonshine still. For sealing purposes, the use of heat-resistant glue and cold welding is allowed, the main thing is to avoid rubber gaskets.

Also, to seal the tubes, you can use organic matter – the usual dough, which does not affect the distillate. There are two drawbacks: a lot of time is spent on kneading and sealing joints, and after distillation, the dried dough has to be scraped off.

The assembled moonshine must be airtight. If steam seeps through the tubes, it is best to stop the distillation, let the equipment cool down, repair the breakdown, and only then continue the distillation. Depressurization is not only dangerous as a fire, but also leads to significant losses of moonshine (10-70%).

Distillation cube

It is a container in which the mash boils during the heating process. Parameters:

1. Material. Aluminum – most often found in “Soviet” moonshine stills due to the wide distribution of aluminum milk cans. Aluminum partially reacts with acids and alcohol in mash, therefore, with frequent use, aluminum stills (especially old ones) become unusable after six months – a leak appears.

Enamelware is neutral to acids and alcohols. With proper use (no bumps or scratches to the enamel), it can last 3-5 years even with regular use.

Food-grade stainless steel is the best and most reliable option, but stainless steel cubes are expensive, often under their guise they sell ordinary galvanized or nickel-plated steel, which is not so durable.

Copper cubes are also suitable, however, in most cases this is an unreasonably expensive solution, especially for beginner moonshiners.

2. Volume and dimensions. The volume of the distillation cube depends on the needs of the moonshiner, the best option for home use is 25-35 liters.

Attention! For safety reasons, the distillation cube can be filled with mash up to a maximum of 80% of the volume, consider this when choosing a container. It is also very important that the lid is removable and that the neck width is large enough for comfortable cleaning of the container after distillation.

The volume of the cube is calculated based on the needs of the finished product. For example, in a container of 30 liters in one distillation, you can get up to 2,88 liters of pure alcohol (or 7,2 liters of moonshine with a strength of 40%). The maximum load of mash is 24 liters (30 * 0,8 = 24). The average strength of a properly made mash is 12%. The amount of distillate at the exit is 24 * 0,12 = 2,88 (in terms of absolute alcohol with a strength of 100%). In practice, there will always be a loss of moonshine of 8-15%.

We should not forget about the dimensions. The alembic should at least fit on a stove or other heating element, be stable and not block the access to the entire apparatus. This is the basis of safety engineering.

3. Choosing the right container. Often, in home moonshine stills, containers are used that were originally intended for other needs: milk cans, pressure cookers or capacious enamel pots.

The cube must be reliable – expand when heated, withstand high temperature and pressure (180-220 Pa). Homemade welded containers are very dangerous, as there is a risk that the weld will burst at the most inopportune moment.

A significant drawback of pressure cooker cubes is their small volume, but these containers are initially sealed. The only modification required is to drill a hole in the lid for the steam outlet tube. The design of a moonshine still from a pressure cooker is described in a separate article.

Enameled pots are convenient in that you can not pour the mash that has won back, but immediately put it for distillation as it is (this is wrong, since the heated sediment increases the amount of harmful impurities in the moonshine, worsens the aroma and taste). The disadvantage of the pan is that it is difficult to seal the lid.

A milk can made of aluminum or stainless steel is the most practical solution. The only drawback of cans that requires mandatory elimination is the rubber gasket on the lid. The fact is that alcohol vapors absorb substances from rubber, this negatively affects the quality, taste and smell of moonshine. Rubber gaskets should be replaced with silicone ones (made from aquarium silicone).

How to make a distillation cube of a moonshine still from a can

It is not enough to correctly determine the volume of the container, you also need to prepare the cube for use – drill a hole for steam, seal the lid and connections. Next, we will consider the refinement of the container using the example of an old milk can, but this method of sealing the lid is suitable in other cases.

Can refining technology:

1. Remove the rubber gasket from the cover.

2. Apply aquarium silicone sealant to the metal edges of the lid and leave to dry completely. Repeat the procedure 2-3 more times.

3. Apply cellophane to the neck of the can and close the lid. Leave for a couple of hours until completely dry. You will get a silicone seal that replaces the rubber gasket.

An alternative, simpler sealing method is to overlap the rubber with several layers of fum tape and boil for 60 minutes in boiling water.

4. Make a hole in the lid of the can for connection with a coil or dry steamer. If the inner diameter of the coil is 12 mm, the suitable hole for the pipe in the can is 22 mm and the thread is 0,5 in. Adapters are sold at plumbing supply stores.

To extend the life of the can, wash the can after each distillation with soap and plenty of running water. The use of soda and other cleaning products is strictly prohibited.

moonshine refrigerator

It consists of two parts – a coil (swirled tube) and a reservoir for cooling this tube. The cooling compartment is the most important element of the whole structure, on the functioning of which the quantity and quality of moonshine depends.

Coil parameters

1. Material. Should not react with alcohol (or have minimal contact), be safe and non-toxic, withstand high temperatures (up to 100°C), and have high thermal conductivity. Based on the requirements, four options are possible: copper, aluminum, stainless steel (food grade) and glass.

Copper has the highest thermal conductivity, another advantage is the relative ease of processing (soldering is possible). But this material has one feature – the copper coil requires periodic cleaning with vinegar or citric acid with boiling water (preferably after each distillation), otherwise the plaque accumulated after oxidation with alcohol will negatively affect the quality of moonshine.

All moonshiners complaining about copper don’t clean their machines well. In the world practice of distillation, copper is considered the best or even the only permitted material (France, Scotland) for the manufacture of distillers (alambiques). Slight oxidation of copper with alcohol improves taste, as it reduces the amount of impurities with a bad smell, and increases the concentration of substances that make moonshine soft.

The second most thermally conductive material for the coil is aluminum (1,6 times worse than copper). The advantages of aluminum are availability, low cost and ease of processing. But there is also a drawback – minimal oxidation, which, unlike copper, does not release useful substances into moonshine, so aluminum coils are not very common.

In terms of thermal conductivity, food grade stainless steel is 3-4 times inferior to copper. But this material does not react with alcohol and does not oxidize. Another disadvantage, along with low thermal conductivity, is the relative complexity of processing.

It is not possible to make a glass coil at home; without special equipment, it is easier to buy a ready-made laboratory device. Glass is inert to alcohol, but is very brittle and has low thermal conductivity.

2. Dimensions and thickness of the tube. The longer the tube, the greater the area of contact between the steam and the cooling element. But there is also a side effect of a large length – the hydraulic resistance increases (the condensed vapors move through the tube already in a liquid state), which reduces the speed of the haul.

The optimal length of the coil tube (before bending) is 1,5-2 meters.

The larger the inner diameter of the coil (section), the lower the hydraulic resistance and the more efficient the cooling (due to the increase in the area of contact between the steam and the walls). But pipes of very large diameter are bulky, require a lot of water for cooling and are difficult to process, so you have to look for a “golden mean”.

The recommended inner diameter of the coil is 8-12 mm.

The minimum wall thickness increases thermal conductivity, which improves the condensation of alcohol vapors. But too thin tubes are very fragile and, with intensive use of the moonshine still, quickly break.

A suitable coil thickness is 0,9-1,1 mm.

3. Orientation in space. There are three connection options: horizontal, vertical and inclined.

Ceteris paribus, the vertical arrangement of the coil is the most correct, since the condensed moonshine flows into the receiving container by gravity, without creating obstacles to the movement of alcohol vapor. Steam can be fed into the vertical coil from above or below. To minimize resistance, properly direct the steam to the top.

Refrigerator Tank Parameters

1. Substance. At home, the coil is cooled with air, water or ice. The vast majority of designs use water cooling, as the simplest and most efficient.

2. Scheme of heat removal. Systems are open (work on running water) and closed (water remains in the tank without circulating, for example, the coil is lowered into a bucket). In terms of implementation and economy, closed systems are simpler and more profitable, but they cool the coil worse, which increases the loss of moonshine and has a bad effect on quality.

Flow circuits are more difficult to manufacture, use more water or energy to pump (circulate a steady volume of water to save money), require a smaller tank, and all other things being equal, produce high quality distillate.

From a properly made refrigerator (coil plus water circulation system), moonshine comes out cold or at room temperature, but not warm or hot. At the same time, it is important to choose the optimal heating intensity (do not exceed the maximum allowable heat supply power) so that the entire system can effectively cope with steam condensation.

3. Direction of water supply. It is correct to supply water to the refrigerator from below, and to remove it from above, so that the water moves towards the steam, creating a counterflow, otherwise the lower part of the coil will not cool well.

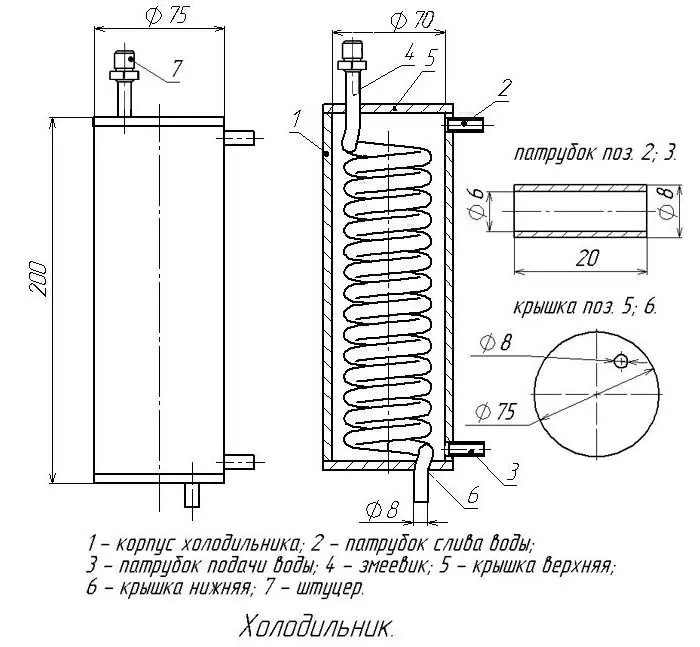

Production of a refrigerator (cooler)

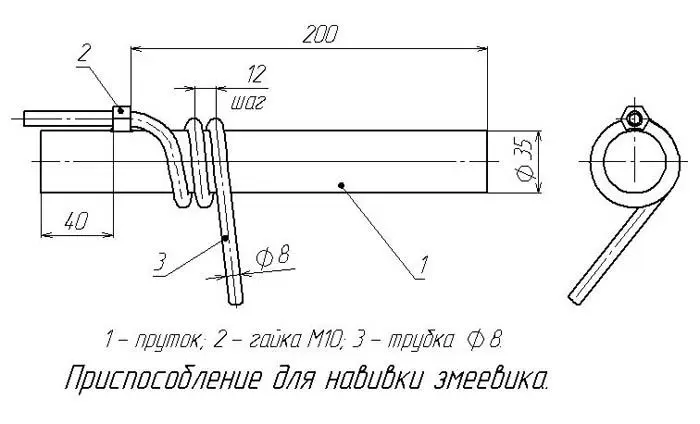

You will need a copper, aluminum or stainless steel tube with a length of 1,5-2 meters, a diameter of 8-12 mm and a wall thickness of 0.9-1.1 mm. A plastic or metal pipe with a diameter of 75-80 mm is suitable as a tank for installing a coil. A drawing of a moonshine refrigerator is shown in the photo.

Sequencing:

1. Fill the coil tube with sand, soda or other dry, loose material so that the metal does not flatten when curled. If there are no bulk materials at hand, the tube can simply be filled with water and frozen.

2. Hammer the ends with wooden pegs (chops) so that the sand does not spill out. Can be tightly clamped or soldered. It is desirable to weld a nut on one of the ends.

3. Wind the tube around any smooth, cylindrical object with an even section of a suitable diameter (according to the drawing – 35 mm). The pitch between the turns is 12 mm.

The number of turns in the coil is not of fundamental importance, with the values u12buXNUMXbof the length, diameter and thickness indicated in the article, it is correct to take a step between the turns of XNUMX mm.

4. Release the ends of the finished coil. Pour sand, rinse with water under pressure.

5. On the body of the cooler, install branch pipes for supplying and discharging water.

6. Place the coil inside the housing. Install plugs at the top and bottom. Seal all connections.

The speed of the cooler of this design is up to 3 liters of moonshine per hour.

Sukhoparnik and bubbler

Optional, but desirable (especially for beginners) moonshine still modules.

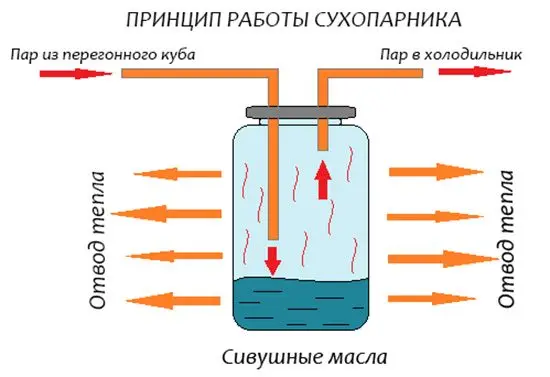

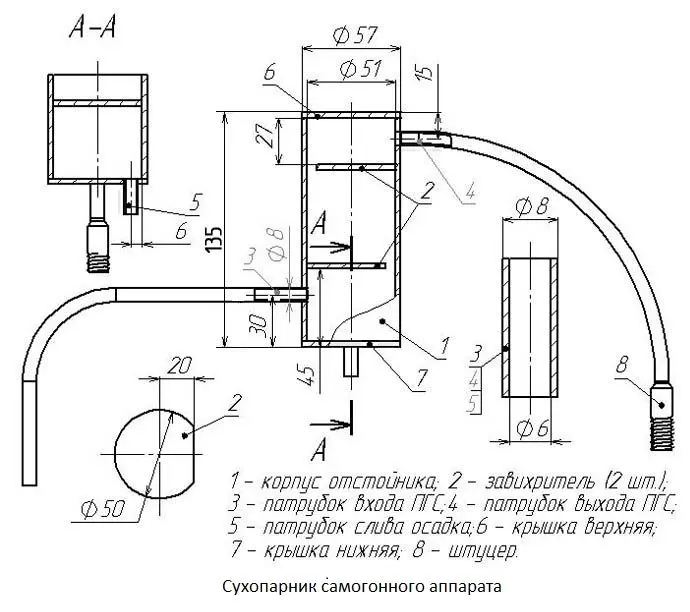

Sukhoparnik – a sealed glass or metal container between the distillation cube and the refrigerator, entering which the vapors are first cooled, and then some of the substances boil again and move to the coil.

The principle of operation of the dryer. Due to a sharp decrease in pressure (the volumes of the supply pipe and the jar differ hundreds of times), the temperature drops, as a result, the vapor passes into the liquid phase (condenses), but is immediately heated by a new portion of hot steam from the cube, again turning into a gaseous state. But some of the water and fusel oils with a high boiling point do not have time to boil during this short moment of change in the state of aggregation and remain at the bottom of the tank.

Bubbler in moonshine still – a device designed to pass alcohol vapor through a layer of liquid (water). Structurally, it differs from a dry steamer only in the presence of water in the container before the start of distillation (not always), and in the fact that the steam supply tube is lowered into the jar almost to the bottom. The purpose and principle of operation of the bubbler are the same as those of the dry steamer.

Advantages of a dry steamer (bubbler):

- is a protection against splashing – hitting the home brew in the finished moonshine with too much heat;

- makes the distillate stronger;

- cleans moonshine from some fusel oils (only a small part);

- allows you to aromatize alcohol during distillation (it is enough to put citrus fruit zest, apple slices, etc. in a jar).

It is advisable to use one steamer or bubbler in the moonshine still. Sequential installation of 2-6 pieces only leads to an increase in the strength of moonshine, but does not affect cleaning.

If the moonshine is strong at the outlet, for example, even 80-90 degrees, then this does not mean that the drink is well purified, it’s just that water remained in the steamers and (or) bubblers, which should have condensed in the coil, reducing the strength of the distillate. All harmful impurities that can be cleaned with a dry steamer remain in the first can, and in the following cans only water is removed from the moonshine. You should not think that according to the degree of purification, 6-8 dry steamers can replace rectification or fractional distillation, this is physically impossible.

How to make a steamer or bubbler

The capacity of the steamer (bubbler) should be 10 times less than the volume of the distillation cube.

You need:

- a glass jar with a metal lid or other airtight container;

- 2 fittings;

- 2 nuts;

- marker;

- awl;

- heat-resistant adhesive or cold welding.

Instructions:

1. Mark the diameter of the holes in the places of the intended connection: attach the fitting to the cover and circle with a marker.

2. Make holes. The easiest option is to drive the awl along the drawn lines until the metal of the cover is rubbed through.

3. Install fittings and secure with nuts. For sealing, process the holes on the outer and inner sides with cold welding or heat-resistant glue.

4. When connecting to a moonshine still, it should be borne in mind that in the steamer the inlet tube should be 15-30 mm lower than the outlet tube (it should be lowered deeper into the jar). In the bubbler, the inlet tube runs along the entire height of the can, without touching the bottom at a distance of 2-3 cm.

If the bubbler is connected incorrectly (steam is supplied through the short end, but tries to exit through the long one), the pressure in the can increases significantly and an explosion may occur!

There is only one drawback of bubblers and dry steamers from the can – there is no drain for the accumulated liquid (you have to unscrew it), and during fractional distillation it is desirable to clean the container before selecting the “body” (main fraction).

Ways to heat the moonshine still

1. Open fire. In most cases, this refers to heating on a gas stove or burner, but there are also coal and firewood. Advantages of this method: simplicity, availability and often economy.

Disadvantages:

- high inertia – it will not be possible to quickly reduce or increase power, as a result, it is difficult to control the temperature in the cube, experience is required;

- it is very difficult to insulate a distillation cube to reduce heat loss in order to save money;

- installation of automation is practically useless;

- high fire hazard of open fire.

2. Built-in electric heating elements. Devices (one or several at once) are mounted directly into the cube. Suitable heating elements made of stainless steel or brass.

Advantages:

- fast temperature change (high controllability);

- the ability to mount automation and insulate the cube.

Disadvantages:

- solid particles can stick to the working surface of heating elements, careful filtration of the mash is required before distillation;

- often heating on electricity is more expensive than gas;

- heating elements burn out from time to time.

3. Induction cooker. It works by electricity, it can be stationary and portable (it is used more often in home brewing).

Advantages:

- low inertia – quick change of heating intensity;

- good temperature control – induction cookers are equipped with automation, no need to install separate blocks;

- in comparison with heating elements, they evenly heat the entire surface of the bottom of the cube, burning of the mash happens in rare cases.

Disadvantages:

- the cost of the induction cooker is quite high;

- only distillation cubes made of materials containing a magnet (stainless steel, cast iron) can be used, in turn, aluminum and copper containers without magnetic inserts welded to the bottom are not suitable for heating.

4. Heating with steam (steam generator). First, the water is brought to a boil and served directly into the container or on the outer walls. The system allows you to control (automate) the entire process and eliminate the risk of burning, therefore it is suitable for the distillation of thick brews. But in view of the complexity of the implementation of the design and the need to purchase (manufacture) special equipment (steam generator), it will not be further considered here.

Installing thermometers in a moonshine still

You can do without measuring the temperature, but a properly installed thermometer allows you to change the container in time during fractional distillation and adjust the intensity of heating.

In moonshine stills, three types of thermometers are used (according to the principle of operation):

- bimetallic – a metal tape or spiral acts as a sensor;

- electronic – a special conductor changes resistance with temperature fluctuations;

- digital – measurements are recorded due to changes in pressure.

The most reliable are bimetallic thermometers, but the accuracy of these devices leaves much to be desired. Electronic thermometers are much more accurate, but with the slightest impact they can break or show the wrong temperature. Digital thermometers are leaders in accuracy, but are expensive.

During distillation, one cannot rely entirely on the readings of a thermometer, especially the first time when the operating modes of a home-made moonshine still have not yet been tested. Temperature values are auxiliary data. At the output, moonshine should be cold or at room temperature, and during fractional distillation, the output should be divided into fractions correctly by pure alcohol, sugar content in mash or by smell (the method of experienced distillers).

Mount. The thermometer in the moonshine still can be installed at the exit from the cube (in the upper part) or before entering the refrigerator. The second option is preferable, as it allows you to measure the temperature of the steam before condensation. But the thermometer in the cube (the first case) shows the degree of heating of the mash, which is also important. Conclusion: if possible, it is advisable to mount two thermometers at once.

For installation, it is enough to make a hole, the diameter of which matches the diameter of the thermometer’s installation cylinder (fastenings with Velcro and plastic clips are not suitable). From the inside, fix the cylinder with a bolt and fix the structure with a nut. Then insert the thermometer itself.

Attention! When you first start a home-made moonshine, you should test it by distilling water, and not immediately fill in the mash. Water distillation is safer, immediately shows problems (if any) and washes well all parts of the structure.