Contents

Buying a new mini-tractor is expensive and not everyone can afford it. However, it is difficult for the owner to take care of a home farm without equipment. Craftsmen get out of the situation quite simply. They make homemade tractors from old parts or remake walk-behind tractors. How this all happens in general terms, we will now try to consider.

Features of assembling a homemade tractor

It is impossible to provide exact homemade assembly instructions, since the entire technical part of this process depends on the spare parts available. To understand how to make a tractor with our own hands, we will consider the main components of this technique.

Maybe someone will not be satisfied with such an answer, because every person is looking for specifics. Let’s talk about why this happens. For example, let’s take the owner’s available motor. It can be diesel and gasoline with air or water cooling. These technical characteristics must be taken into account, since the entire design of the homemade product will depend on this. A fan will have to be installed in front of the air-cooled motor. The water cooling system is complex and has a completely different device.

If it is decided to assemble a homemade tractor from a walk-behind tractor, then the engine, wheelset and gearbox remain native. You only have to weld the frame and add another axle for the wheels. When reworking the walk-behind tractor, the native wheelset is the leading one. It can be located behind or in front. It all depends on which part of the frame the motor will stand on.

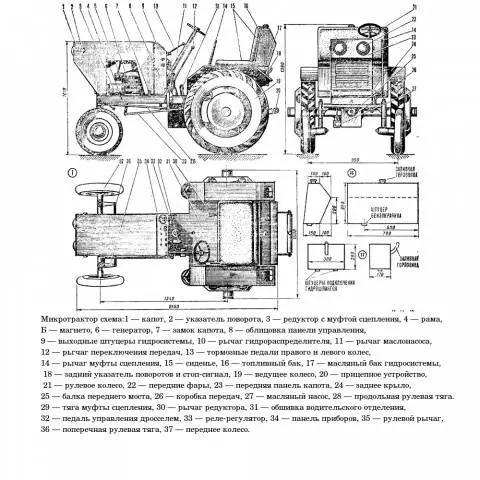

Regardless of the available spare parts, you need to start assembling a homemade tractor by drawing up a drawing. Having an exact diagram at hand, you will be guided by what and where to put. We suggest looking at the photo for an example of a tractor drawing with the layout of all nodes.

They begin to fold the tractor with their own hands from the manufacture of the frame. Regardless of the existing motor, even if you are remodeling a walk-behind tractor, the design is made in two types:

- Fracture. This frame consists of two semi-frames, interconnected by a hinged mechanism. A homemade tractor with a breaking frame is characterized by high maneuverability. On the front half-frame they put a motor with a gearbox. A rear axle and a towing device for additional equipment are attached to the second half-frame.

- Whole frame. The budget option is considered a classic. The frame is a single fixed structure with two traverses and spars. Jumpers are placed for amplification. Sometimes the front frame is made narrower than the back. That is, it turns out the shape of a trapezoid.

A frame of any type is welded from a channel. For jumpers use a profile pipe. Useful metal corners of different sizes, as well as sheet steel with a thickness of 5-10 mm.

The video provides an overview of a homemade tractor:

Spare parts for tractor assembly

So, we continue to consider how to make a homemade tractor, and now it’s time to choose spare parts:

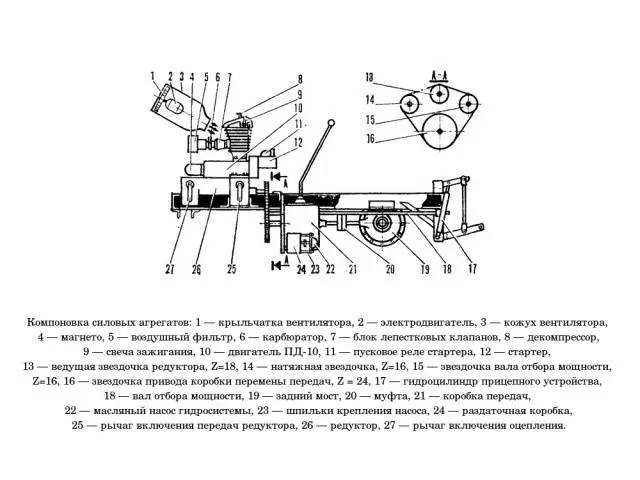

- We have already talked about the motor, but we will stop again. For a tractor, it is desirable to find an engine with a capacity of about 40 horsepower so that the equipment can cope with any task. In general, the craftsmen put everything that is on the farm: a motor from a Moskvich, a motorcycle, a power plant, etc. If they remake a walk-behind tractor, then the problem with the motor disappears. It is reasonable to convert a walk-behind tractor to a tractor if its power is more than 6 horsepower. Otherwise, the homemade product will turn out to be weak, and there will be little help from it on the farm. In addition to power, it is important to take into account the operating speed of the engine. Speed is not an important parameter. The motor should gain a lot of torque at low speeds. Diesel engines have these characteristics.

- When altering the walk-behind tractor, the gearbox remains native. For another engine, the gearbox will have to be selected from other equipment. This assembly is best suited from a GAZ-51 or 53 car. There is a lot of work to be done here to remake the clutch basket so that it fits the mount to the existing engine.

- It does not hurt to install a PTO on the tractor with your own hands. Then homemade with hydraulics will significantly expand its functionality through the use of attachments.

- Wheel sets are usually used from passenger cars. From there they take the rear axle. If the axle shafts are too long, then they are shortened. When altering the walk-behind tractor, the driving wheel pair remains native. If the engine from the walk-behind tractor is placed on the back of the frame, then the track width is increased for the stability of the tractor. On a homemade tractor, the front beam is ideal from a loader. You can simply make a balancing beam yourself on one hinge in the center.

- Steering is best found from a car. When reworking the MTZ walk-behind tractor, a three-wheeled tractor is sometimes assembled. In this case, the front wheel together with the steering is removed from the motorcycle. But motorcycle handles or handles native to the walk-behind tractor are inconvenient to operate while reversing. Here it is better to give preference to the traditional round steering wheel.

- Another important node is the towing mechanism. It is welded onto the tractor with your own hands to the back of the frame. This is where the cart will go.

- The braking system when reworking the walk-behind tractor is used native. In another case, it is also removed from another technique. Do the same with the fuel tank.

After installing all the nodes, the tractor is hung with a sheathing, a seat is placed, headlights are attached, and electrical wiring is laid.

Production of a cabin for the MTZ tractor

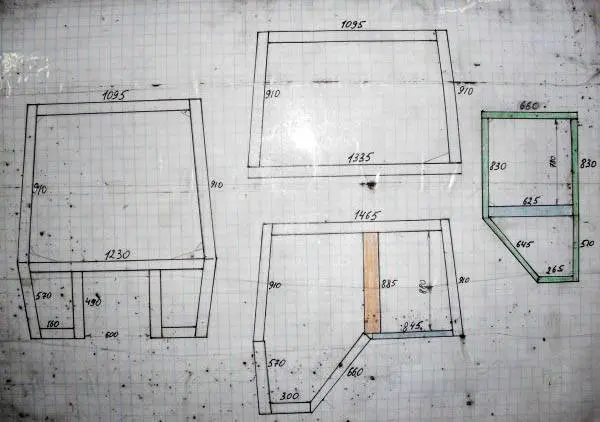

The tractor can be used in the summer without a cab, but the comfort of work is greatly deteriorating, and with the onset of autumn, in general, it will not be possible to drive equipment. A homemade cabin for a tractor is made from sheet steel. First you need to make a drawing. We take the cab from the MTZ tractor as a basis. The photo shows a diagram of the fragments of the structure. On it you can assemble a cabin for your tractor.

The manufacturing process of the cab for MTZ consists of the following steps:

- If the dimensions on the drawing do not suit you, you can change them. During independent calculations, front sight glasses are always taken as the basis. The roof is made at least 25 cm higher than the height of the driver sitting behind the wheel.

- The first frame is assembled from a wooden beam. All elements are connected with self-tapping screws.

- Further, along the outer body of the wooden frame, they begin to build the skeleton of the future cabin of the MTZ tractor. To do this, adjust the metal pipe to the size of the wooden elements. The connection is made by welding. After checking the parallelism and evenness of all joints, the corners of the structure are closed with a profile.

- The finished skeleton of the MTZ cabin is placed with the roof on the ground, after which the bases for the sight glasses are welded from the inside.

- Fragments for the roof of the MTZ cab are cut out with a grinder from sheet steel 1 mm thick. It is welded to pieces of a pipe with a diameter of 100 mm cut along. Further, this entire roof structure is attached to the common cabin frame. Wings and floor need to be made stronger. Sheet steel 2 mm thick is better suited here.

- The door frame is welded from a profile pipe. It is important not to forget to put gas lifts. Given the location of the side windows, the angle of the central and rear pillars is selected, after which the crossbars are welded.

- The final work is the installation of glass. The interior lining of the cabin is usually made of foam rubber, and leatherette is pulled on top.

On this homemade cabin is ready. Now it remains to fix it on the tractor. The outside of the cabin needs to be painted. In addition to the aesthetic appearance, the paint will protect the metal from corrosion.

The video shows a homemade cab for the MTZ tractor:

Assembling appliances at home is a difficult task. It requires a lot of knowledge, as well as the ability to perform welding and turning work.