Contents

Each owner of a private yard acquires a cellar. It is dug under the house, garage, barn or just on the site. However, at any location, in order to get inside, you need a staircase to the cellar, and it is very reliable and convenient. You will have to walk up the stairs with a load. Perhaps children or the elderly will descend into the cellar. The staircase should provide a safe and comfortable descent without taking up extra space inside the cellar.

The main requirements that should be followed when calculating the dimensions of the stairs

So, the cellar is located in the garage, under the house or on the site, you will need a convenient staircase to go down inside. An attached structure is considered the easiest for basements, but it will not be possible to comfortably descend or ascend it. But you still have to carry a load with you, for example, potatoes or conservation. The best option is a marching staircase. If the size of the cellar allows, then it is better to stop at this option.

Having decided on the model, you should not immediately start construction. First make the calculation of the stairs, adhering to the following rules:

- The width of the march depends on the dimensions of the cellar. There are no special requirements for this parameter, but it is also impossible to build a structure that is too narrow. Usually the width of the stairs to the cellar is from 700 to 900 mm. A person must freely walk up the steps with a bucket of potatoes or other cargo.

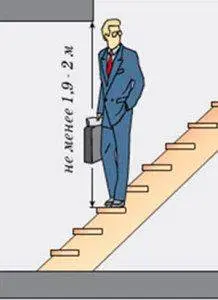

- The correct calculation of the clearance provides exactly the same comfort of climbing stairs. This parameter refers to the distance from the steps to the ceiling of the cellar. Always measure the narrowest section. The distance from the bottom step to the ceiling should be 200 mm more than a person’s height. When building a new cellar, a standard clearance of 2 m is made. If the clearance is less than normal, you will always have to climb out of the cellar in a bent position on the stairs so as not to hit your head on the ceiling.

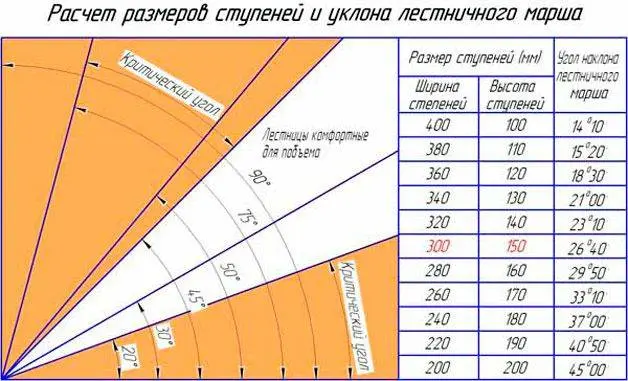

- The second important indicator of a comfortable descent is the slope of the stairs. It can be in the range of 22-75о. Under a steep slope from 45о put only ladders in the cellar. On flights of stairs make a more gentle descent. The smaller the slope, the more comfortable it is to move along the march.

- A convenient step width is considered to be within 300 mm. Too narrow or wide step will cause discomfort to a person while walking.

- The step height parameter is 150–200 mm. Moreover, they should all be located at the same distance from each other. Only the lower and upper steps can be offset. You can’t do a lower height, as the step will become more frequent, which will affect fatigue while walking. With a higher step height, you will have to lift your leg a lot.

- The number of steps depends on the length of the staircase itself. It is easy to do your own calculations here. The length of the stairs is taken and divided by the height of the step. If the result is, for example, 16,6 pieces, then one step at the top or bottom can be done with an offset.

Following these recommendations, it will be possible to build a comfortable staircase. To help the developer, the photo shows a table of calculations for the flight of stairs.

What material to make a staircase in the cellar

There are different options for the manufacture of basement stairs, and they all differ in the choice of material. It will depend on this: how easy it will be to build a structure, what its final cost and service life will be.

Tree

The easiest way is to build a ladder with your own hands from wood, as this material is best processed. The only drawback is the shorter service life of the structure, in relation to analogues made of metal or concrete. Inside any cellar, humidity is always increased. The wood begins to become covered with fungus, and over time acquires a rotten structure. A wooden staircase impregnated with an antiseptic and opened with varnish or paint will last a little longer. However, it is desirable to give preference to such a design in the presence of the most dry cellar.

Metal

The golden mean between wooden and concrete stairs are metal structures. For their manufacture, pipes, a corner, a profile or a channel are used. The steps are cut from sheet steel 3–4 mm thick.

The metal staircase to the cellar is welded from cut blanks. The construction is solid and can last for years. However, metal is also afraid of dampness. Over time, the flight of stairs begins to destroy corrosion, that is, the familiar rust appears to everyone. The steel structure will have to be tinted at least once every three years.

Concrete

The most reliable and durable is a concrete staircase, but it takes up a lot of space and is only suitable for a large cellar. It is very difficult to make such a design. First, formwork will be required. Secondly, in order for the structure to be strong, it must be well reinforced. And the biggest problem is working with concrete. It will take more than one batch, and all this solution must be manually lowered into the cellar to fill each step.

Despite a lot of difficulties, concrete is not afraid of dampness, and the reinforced concrete structure will gain strength every year in the cellar. The only downside is the abrasion of the concrete while walking. But it is unlikely that a person will erase them in his entire life. In extreme cases, the march can be painted or tiled, but not slippery.

The video talks about the concrete stairs:

Options for arranging the descent into the cellar

Now we will look at a photo of the stairs to the cellar, and a brief description of their manufacture. In general, such a design is designed at the stage of building a house or garage. But, if the cellar was not provided before, now you have to correct the situation.

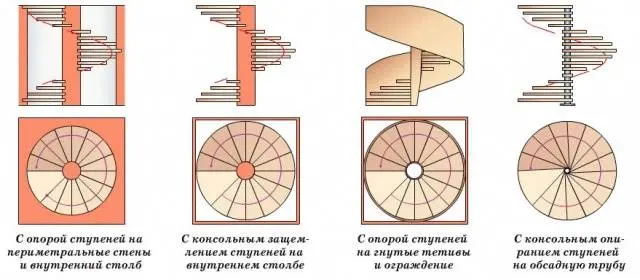

Screw design

If the hole in the cellar is small, then the ideal option would be a spiral staircase that occupies a minimum of free space. For the manufacture of the structure, wood or metal is suitable. Even a combination of these two materials is allowed. Let’s say the base is made of steel, and the steps are made of wood.

The spiral staircase consists of two main parts:

- The base is the rod. All steps will twist around it. The ideal solution is to use a steel pipe for the rod.

- The second part of the design is the steps themselves and the support flanges.

Railings are an integral part of the screw structure, although in some cellars they can be dispensed with.

Screw design is not simple. Here you will need to develop a complex project with accurate drawings. In the absence of even the slightest experience, the manufacture of a screw structure must be entrusted to specialists.

Kossourach construction

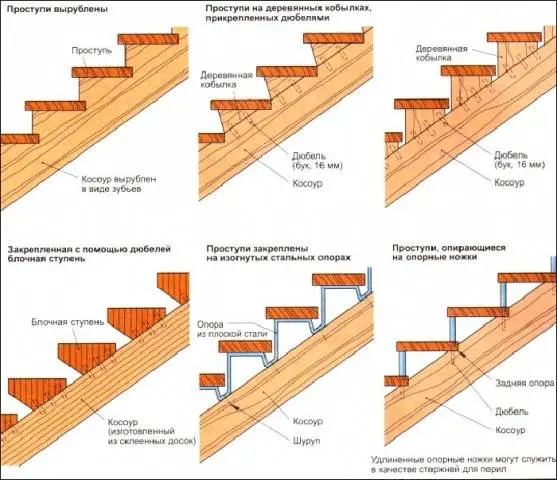

Now we will look at how to make a staircase to the cellar with our own hands on stringers. This option is the simplest and most affordable for an inexperienced person. The best option is a ladder on two or three stringers. In the second option, additional strength is provided due to the central element.

For a march on stringers, there are two ways to fasten steps:

- If the kosour is made of a wide board, then triangular cutouts are made to fasten the steps.

- In the second case, fillies are attached to the end of the stringers. Steps will rely on these additional elements.

If a decision is made to make a structure without fillies, then in addition to the width of the board, attention should be paid to the type of wood. Stringers must maintain their strength throughout the life of the stairs. It is best to use an oak board or beech. The structure of wood is resistant to heavy loads, and tolerates dampness well. Boards must be chosen even without a single knot.

For the manufacture of the steps themselves, a board with a thickness of 50 mm is used, provided that the width of the march is 0,9–1,1 m. In general, when making calculations, they adhere to the indicator at which the thickness of the step is taken twenty times less than the width of the stairs. Deviations are allowed only in the direction of increasing thickness. However, at the same time, the mass of the structure itself also increases. This means that the stringers are made from a board with a large cross section.

A flight of stairs is fixed to the vertical posts, which are firmly screwed with anchor bolts to the concrete floor of the cellar. Railings are an optional element, but necessary. They are installed at a height of 800–900 mm from the steps.

The video provides an overview of the stairs on the stringers:

Bolts construction

The manufacturing technology of flights of stairs on the rails came from Germany. Now it is gaining great popularity in our country. A design feature is the steps connected by bolts from the inside. At the same time, they seem to be pulled together with each other. Fasten the steps to the bearing wall with a special pin. Here it is called Bolts.

Immediately it is necessary to determine the dignity of the march on the Bolts. First, the design is easy to install. Secondly, a strong mount ensures the reliability of the structure. Although the opinions of experts in this regard differ. Some talk about the lack of strength of such a descent for the cellar, others say the opposite. But the last word remains with the owner of the cellar.

In the cellar, the stairs on the bolts can be made of two types:

- Let’s say the width of the march is limited to 1 m, and boards 60 mm thick are taken for the step. The supporting element of this structure from the outside is the wall. From the inside, the steps are tightened with bolts. The railings themselves are attached only to the body of the stairs, and do not require additional support.

- If the march to the cellar is fastened with bolts from the side of the wall, then the supporting handrail acts as a support, as well as the screeds of the steps themselves. For this design, a board with a thickness of 50–60 mm is used. The flight of stairs is held by the main handrail thanks to the railing posts.

The stairs to the cellar on the rails can be installed without a supporting wall. With an increase in the width of the march, thicker boards are used. Naturally, at the same time, the cross section of all other elements of the stairs is increased.

Conclusion

With the independent manufacture of stairs to the cellar, you should not succumb to haste. A poorly planned structure will turn out to be inconvenient for walking, and incorrect calculations can lead to the collapse of the march.