Contents

Your walk-behind tractor in the household will become an indispensable assistant in the cultivation of the garden, caring for animals, as well as performing a number of other agricultural work. Now the consumer is offered a huge selection of such equipment, but not everyone can afford its cost. This does not mean that you should abandon the idea of making your work easier. Now we will look at how to make a walk-behind tractor with our own hands from existing spare parts from old equipment.

Walk-behind tractor device

The general principle of the device of walk-behind tractors of different brands is almost the same. Any unit consists of a motor, gearbox, frame, chassis, clutch and controls. According to this principle, the walk-behind tractor will be assembled with your own hands from old spare parts.

The power of the unit will depend on the found engine. For homemade products, it is better to use an air-cooled motor, for example, from a motorcycle or an arc of similar equipment. The walk-behind tractor can even be equipped with an electric motor with a power of 2 kW or more, only it will have to be connected to a three-phase network. It is difficult to find a single-phase electric motor of such power, and if you run a three-phase one through capacitors, then part of the power will be lost.

The clutch on the walk-behind tractor must be installed when using any type of engine. This node is responsible for transmitting torque to the wheels from the motor. It’s good when a native clutch is available along with a gasoline motorcycle engine. In this case, you do not have to customize anything.

All motors have a high speed, and the walk-behind tractor must move slowly. A gearbox installed between the engine and the drive wheelset will help to reduce the speed. This assembly consists of a set of gears of different diameters, which allow you to reduce the speed of the wheels.

Getting started assembly

When all the necessary parts are selected, you can start assembling homemade products. The first step is to weld the frame. All nodes of the walk-behind tractor will be attached to it. For reference, we presented the frame diagram in the photo.

You can calculate your own sizes, as they may differ from the units available. The frame is made of a metal pipe with a cross section of 32 mm. It’s good if you can bend the whole structure, and the jumpers still have to be welded.

In the diagram, the element under No. 8 is needed to attach a mechanism that allows you to tension the chain. A chain reducer and a running gear will be fixed to item No. 5. You can also attach a transport trolley here.

The following photo shows an air-cooled motor. In the considered design of the walk-behind tractor, the engine from the “Ant” was used.

A mount is installed on the common frame of the walk-behind tractor for the engine. His scheme is shown in the photo. The design is an arc curved from a pipe with a diameter of 32 mm. Three loops are welded from a steel strip in places corresponding to the location of the motor mounting holes.

The motor mount must move along the frame. This is necessary so that the chain can be pulled. After installing the engine, they begin to deal with the muffler. It is taken aside so that the exhaust gases do not fall on the operator.

The next node is a chain reducer. The scheme of its device is shown in the photo. The mechanism has two stages, where the speed reduction occurs due to two sprockets with 57 and 17 teeth.

You can make a wheel pair for a walk-behind tractor yourself or remove it from old equipment. In our example, the assembly was removed from the SMZ motorized carriage. In the photo you can see a diagram of additional nozzles for wheels.

In order for the unit to be made to process the soil, it is necessary to turn it into a motor cultivator. For this, a T-shaped bracket is made of a square pipe. His scheme is shown in the photo.

The result was a basic model of a walk-behind tractor. But after all, equipment is needed to perform different tasks, so the following homemade products will be elements of attachments.

The video shows a homemade walk-behind tractor:

Additional equipment for a homemade walk-behind tractor

The assembled walk-behind tractor from old spare parts is only 50% of success. Further, there is no less difficult work on the manufacture of iron wheels and attachments.

Lugs

There are many ways to make do-it-yourself lugs for a walk-behind tractor, and the first of them is the easiest. To do this, take sheet steel 3 mm thick, cut a strip from it along the width of the tire tread and weld it on top, bent at an angle of 120о, metal plates. The strip with lugs on the tire is pulled together with two studs.

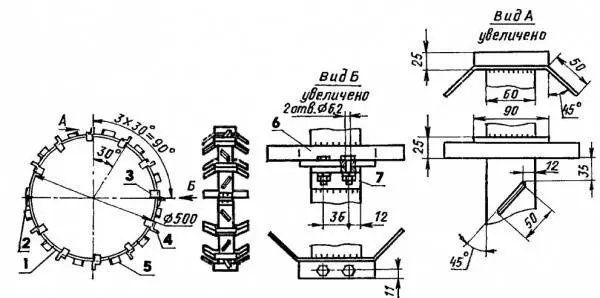

It is optimal to make lugs for a walk-behind tractor with your own hands according to the principle of a factory design. The scheme of such iron wheels is shown in the photo.

The central lugs disc is cut out of 5 mm thick sheet steel. Strips 50 mm wide are cut out of the same metal, after which rings are formed from them. For two wheels, you need 6 pieces. The hooks themselves are cut from a steel strip 8 mm thick. All elements are connected by welding. Axles are attached to the center of the disks. It is better to make them adjustable so that you can change the gauge of the walk-behind tractor.

The mass of each iron wheel will be about 10 kg. This will ensure a reliable hitch of the unit to the ground.

Plow

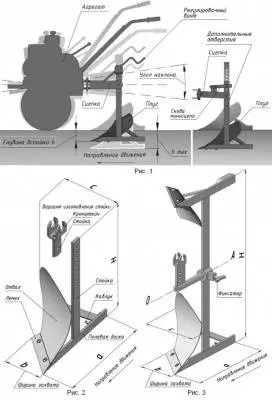

To plow a garden, you need to assemble a plow for a walk-behind tractor with your own hands, the scheme of which we propose to look at in the photo. This typical single case design is suitable for any unit size.

They make a plow for a walk-behind tractor with their own hands using the following technology:

- The rack is made of a steel strip 10–12 mm thick. To adjust the angle of inclination and the depth of immersion of the plow, holes are drilled on the stand in one row. Alternatively, for adjustment, you can make a latch moving along the rack.

- The most difficult thing is to bend the blade. For its manufacture, sheet steel with a thickness of 3 mm is taken. It is better to bend according to the model of the factory plow, otherwise you can make a mistake with the angle. The finished blade is hardened by heating red-hot on fire, after which it is thrown into alkaline water.

- The ploughshare is made of high-alloy steel. It is attached to the dump with rivets so that their hats do not protrude to the surface.

All elements are assembled according to the proposed scheme. When the plow for the walk-behind tractor is completed with their own hands, they try to plow the ground. If all the elements are held at the right angle, and the plowshare is well sharpened, then the plow will smoothly cut off the ground layer without jerking.

Harrow

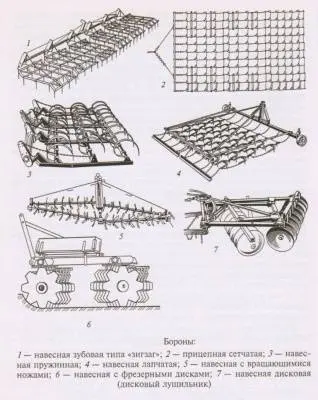

The next element of attachments is to make a do-it-yourself harrow for a walk-behind tractor, which are rotary, disc and tooth.

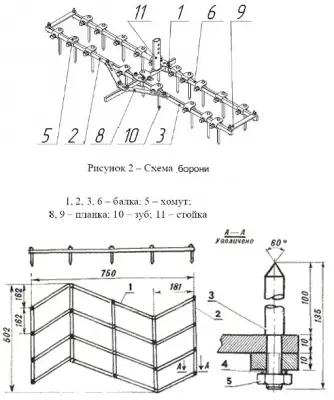

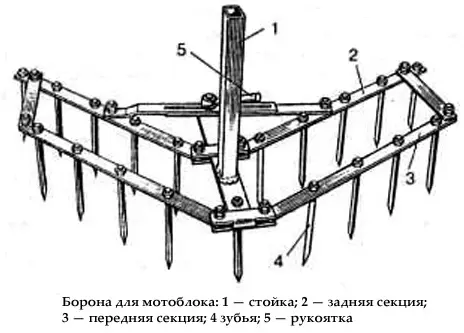

The simplest in design is the tooth harrow. For its manufacture, the frame is first assembled, and then teeth 25–50 mm long are welded at the same distance.

The scheme for manufacturing a tooth harrow is shown in the photo. The frame is welded from a square pipe. It is better not to weld the teeth, but to cut the threads and fasten them with nuts. In the event of a breakdown, it will be easier to replace them.

For longitudinal travel in a homemade harrow, you can install a hinge from a GAZ 53 car. In addition to the towing device, you will need two traction. They will provide better controllability of the harrow.

Trolley

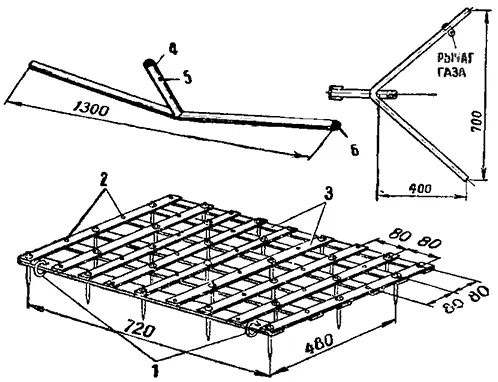

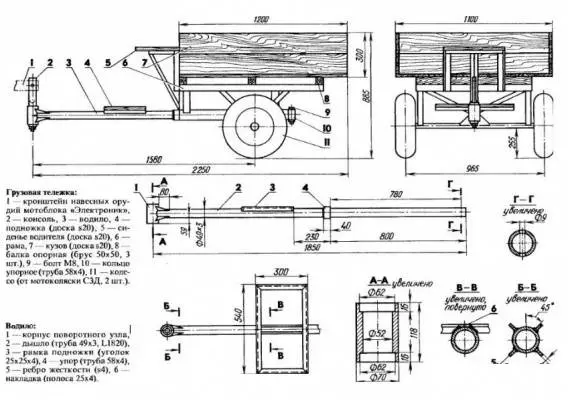

To transport goods, you need to make a do-it-yourself cart for a walk-behind tractor, the diagram of which is shown in the photo.

There are different design options: from simple bodies to dump trucks. In any case, it is imperative for the cart to do:

- The frame is welded from a channel, corner or pipe.

- The body can be made: with a folding tailgate, opening rear and side boards or completely fixed. The best material for manufacturing is tin, and in its absence, you can use a board.

- For coupling with a walk-behind tractor, a drawbar is installed. The length is selected individually so that it is convenient to control the equipment.

- The driver’s seat can be equipped in the body or mounted on the drawbar.

- To connect the hitch of a walk-behind tractor with a drawbar, a hinge is needed. It is better to order it in a turning workshop or remove it from other equipment.

- An axle with a pair of wheels can be removed from other equipment or made from a piece of pipe. But then you have to grind the bushings, fit the bearings and adjust the hubs with the wheel disks.

If you plan to transport heavy loads, then it is better to make a trolley on four wheels. In this case, it is necessary to install shock absorbers.

The video shows a dump truck:

Conclusion

Self-manufacturing of a walk-behind tractor and additional equipment is a rather complicated matter. However, the cost savings are significant.