Contents

Many residents of the private sector are engaged in rabbit breeding. Animals are easy to care for if they are kept in a properly equipped cage. Houses for eared pets are easier to buy, but such costs will pay off for a long time. It will be cheaper to make cages for rabbits with your own hands, and after making the first profit, you can think about factory designs.

Sizes and drawings of cages

The size and design of the cages is determined by the number of animals, as well as the purpose of the livestock, that is, the rabbits are left for fattening, breeding, etc. Let’s look at the parameters by which cages are made for different groups of animals:

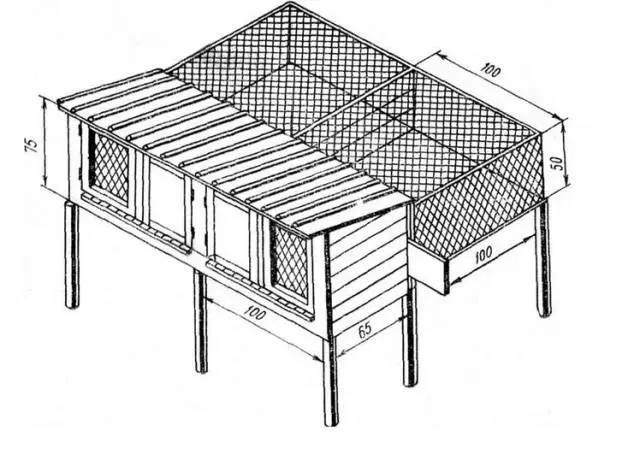

- The rabbits separated from the female are kept in a group cage until the age of three months. Moreover, animals are divided into breeding and slaughter individuals. A house for young rabbits is made 2–3 m long, 0,6 m high, and 1 m wide. Young animals are inhabited by 6–10 heads. Breeding individuals are grouped with a maximum of 6 goals. The photo shows a group cage with young rabbits.

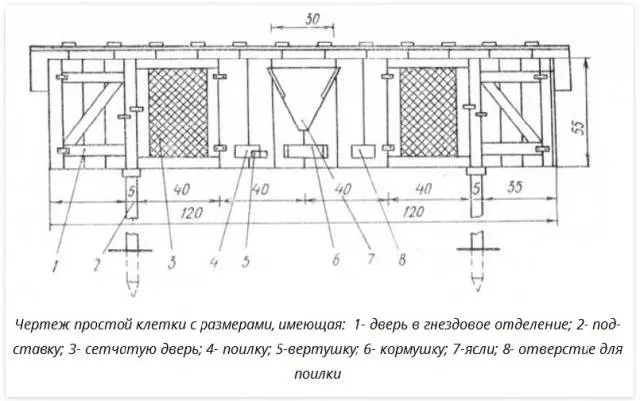

- The following photo shows a diagram of a house with dimensions for two pregnant rabbits. A cell with a queen cell can also be made single. Then its dimensions will be: 1,2×0,7×0,6 m. That is, it turns out half of the house shown in the drawing. The mother liquor can be made retractable, which is recommended by many rabbit breeders. This design simplifies the cleaning of the cage after weaning the young. A mother liquor for a female with rabbits is made: 40 cm long, 60 cm high, 70 cm deep. A hole 20×20 cm in size is cut out on the front wall.

- Now consider the cage sizes for rabbits that have reached puberty. Adults are kept in one- and two-section structures. The length of the first type of house is 0,8–1,1 m, and the second type is 1,3 m. The width of both types of construction is at least 0,6 m. -3 rabbits.

- Young males are kept in groups up to three months of age. If the animals are intended for slaughter, then they are simply castrated. Breeding rabbits are placed in single cages measuring 0,7×0,7×0,6 m. In the photo you can see a detailed drawing with the dimensions of the house for young animals. Simple mesh enclosures are attached to the back wall.

Using the presented drawings of cages for rabbits, you can try to make a similar design yourself at home.

Cell Building Recommendations

Even before the construction of cages for rabbits, you need to decide on the place of their installation. On the site, it is desirable to choose a corner without drafts, but it is better to refuse the south side. In summer, the rabbits will be very hot under the sun. It is important to provide a roof that reliably protects against precipitation. On the houses it is made lean-to, using the cheapest roofing.

Building winter houses for rabbits is much more difficult. Firstly, the floor is not made of a mesh, but a rail is stuffed in 15 mm increments. A solid pallet is installed under the floor. It must be pulled out to clear manure. Secondly, you need to take care of saving offspring in winter. The walls and ceiling of the winter house are insulated with any available thermal insulation. Feeders and drinkers are removable. In severe frosts, food and water will freeze in them. The removable design will allow you to bring the drinker and feeder into the heat for thawing.

Overview of rabbit cage varieties

To make it easier to make a do-it-yourself rabbit cage, let’s look at several popular designs. The photo shows the original solution of the summer house. The design stands on high legs, and under the house and near it there is a mesh aviary. There are two compartments inside: a mother liquor and a place for feeding. The rooms are separated by a plywood partition with a manhole.

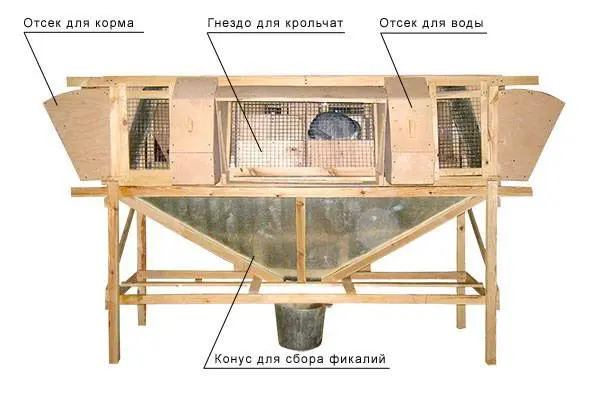

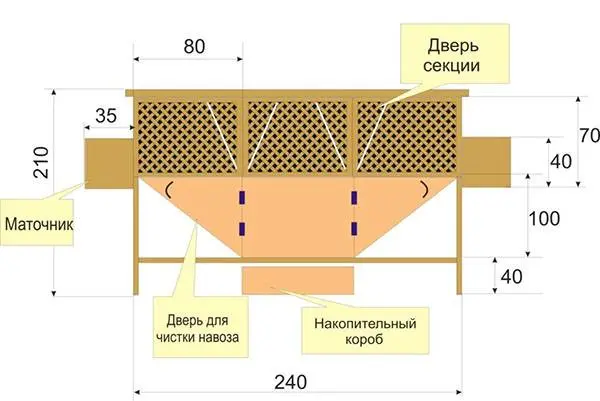

The following photo shows a Mikhailov cage designed for industrial rabbit breeding. The author of the technology provided for the heating of the mother liquor, the ventilation system and other nuances. The chip is a cone-shaped pan for automatic manure removal. The design can be called a mini-farm that allows you to engage in rabbit breeding at a professional level.

If someone wants to know how to make a cage for rabbits by analogy with Mikhailov, he can use a detailed drawing with the indicated dimensions.

No less interesting in the device is the Zolotukhin cell. Its distinguishing feature is the design of the floor. It is made solid from plywood, boards or flat asbestos-cement slate. Reiki and a pallet are not used, and a 20 cm wide mesh is installed on the floor only at the back wall of the house. Manure is removed through it. To make this happen automatically, the floor is equipped with a slight slope.

Feeding troughs are placed outside, and they are made to tip over. This design option is due to the ease of cleaning. The feeder does not have to be removed, but only needs to be tilted and thoroughly cleaned with a scraper.

Another distinguishing feature of the cell is the absence of a queen liquor. The author of the technology suggests that inside the house in the summer to fence off a place for okrol with a board 20 cm wide. The rabbit herself will arrange a hay nest. Zolotukhin assures that rabbits born in such conditions are healthier and rarely pick up infectious diseases. When the kids begin to move independently, the board is removed. There is a lot of free space in the house.

In winter, in such cages, they also get offspring from rabbits, only the option with the board does not work. Instead of a fence, they put a wooden mother cell.

In the video, Zolotukhin Nikolai Ivanovich talks about his cages and the technology for raising rabbits:

The guide for making Zolotukhin cells looks like this:

- For the manufacture of the house will not need expensive materials. Most of them you can find at home. So, the frame of the house, the doors, the base of the partition are assembled from a bar or a thick board.

- On the lower part of the frame, a slope is arranged by adding a horizontally laid board, after which plywood or flat slate is fixed. At the rear wall along its entire length, the floor area is covered with a mesh. The doors where the feeders will hang are also lined with mesh. Only the shutter of the mother liquor is made solid to prevent drafts and get rid of excess light.

- All wooden elements of the frame from the inside of the house are upholstered with sheet metal. It will protect the structure from the sharp teeth of rabbits. A threshold from a board at least 10 cm wide is nailed to the floor from the side of the mother liquor door. It will prevent the babies from falling out of the cage when the sash is opened.

- Zolotukhin’s cells are made multi-tiered. Manure will be discharged through the mesh at the back of the house. To prevent waste from the upper floor from falling into the cells of the lower level, the back paneling is made at an angle. Moreover, the slope is maintained only on the lower cells, and the wall of the upper house remains flat.

That’s all the secrets of making Zolotukhin’s cell. The design is so simple that it can be made and installed on your site.

Self-manufacturing of a single-tiered cage with a mother liquor and a bunker feeder

Now we propose to consider what a step-by-step instruction for a do-it-yourself rabbit cage looks like, equipped with two compartments:

- The fabrication of the structure begins with the assembly of the frame. To do this, a lower frame is assembled from a bar with a section of 50×50 mm. Racks are attached to it, and then the upper harness is attached. When the frame is assembled, a steel mesh is nailed to the bottom frame. Such a floor is made only where there will be a compartment for feeding rabbits. A board is nailed in the mother liquor. Here the floor is made solid without gaps. The optimal grid cell size is 2×2 cm. Coarse-mesh material for the floor is not suitable, as the rabbit’s paws will fall through and get stuck.

- From the board or plywood put the side and back walls. To separate the mother liquor and the place for feeding, a partition is installed. The manhole can be cut rectangular or round, with a diameter of about 20 cm.

- Next, move on to the interior design. First, a cover is placed on the nest. After that, the internal partition of the two compartments is assembled. Here they also provide a section for grass from steel rods and put bunker feeders.

- From above, the structure is covered with plywood. This will be the roof. Doors with handles are attached to the feeders. On the front side of the house, they put a mesh door on the feeding compartment and a solid sash for the mother liquor.

- If the cage is to be installed outdoors, the plywood roof must be protected with a waterproof roof covering. Be sure to provide for a slope towards the back wall so that precipitation does not accumulate on the roof.

The advantage of the design lies in the ease of manufacture and the provided capacious feeder. The bunker is designed for 6 kg of feed, which saves the owner from the daily attachment to the rabbits.

Independent production of a multi-tiered cage

The instruction for the manufacture of a multi-tiered structure differs only in the assembly of the frame:

- The process begins with the assembly of the lower frame. Vertical posts are attached to it. Their length depends on the number of tiers. Moreover, a minimum of 15 cm is added to the height of each house. The stock is needed to form a gap where the pallet will be inserted. The last knot in the frame structure is the top harness.

- Between the racks fasten transverse jumpers. They will hold the houses of each tier. From below, legs are attached to a frame made of thick timber or pieces of steel pipe. They must raise the cage from the ground to a height of at least 40 cm.

- Dividing the houses into several sections will not be simple partitions, but a V-shaped grass feeder. Its frame is assembled from timber. For sheathing, a large-mesh mesh is used or metal rods are attached.

- The manufacture of the mother liquor, fastening of the doors and other internal arrangements are carried out in the same way as they did in a single-tiered cage. When the structure is fully completed, a galvanized pallet is placed under each tier. It needs to be fixed with a slope so that it is more convenient to rake out manure.

Multi-tiered cages are convenient because, if necessary, they can be disassembled into separate modules, the frame can be moved to another place, and the house can be reassembled.

The video shows the process of making cells:

As practice shows, multi-tiered cages are more often popular in household and farming. This is to save space. However, it is not advisable to build a structure more than three levels due to the complexity of caring for it.