Contents

Not every suburban area can fit a greenhouse. Because of this, greenhouses have gained great popularity. They are made independently from improvised materials or bought in a factory-made model. In terms of functionality, a greenhouse is the same greenhouse, only for the winter cultivation of vegetables, the shelter is not suitable due to the inability to organize heating. Among many models, the factory-made Snowdrop greenhouse has gained wide popularity. The design is so simple that any vegetable grower can easily assemble it.

Features of the greenhouse device and factory equipment

Neftekamsk company BashAgroPlast produces greenhouses Snowdrop from plastic arcs sewn into the covering sheet. The product is characterized by light weight, compact size, easy assembly.

The arcs are made of plastic HDPE pipes. Hence the light weight of the finished product. A feature of the design of the Snowdrop is the arcs sewn at the factory into the covering sheet. The purchased greenhouse is completely ready for use, you just need to unpack it and stretch it over the garden. The snowdrop is completed with plastic stakes 26 cm long. They are inserted into the end of each pipe, after which the arcs are stuck into the ground. To install the Snowdrop, you do not need to make a base, and a large supply of covering cloth from the ends allows you to organize strengthening extensions of the greenhouse.

The factory greenhouse Snowdrop goes on sale in the following configuration:

- A set of plastic arches is made of HDPE pipes with a diameter of 20 mm. The arches are a good support for the covering material and do not corrode. The number of arcs depends on the length of the greenhouse.

- Convenient installation of arcs into the ground is provided by plastic stakes 26 cm long. One spare pin is always included in the kit. Let’s say a Snowdrop 6 m long has 7 arcs, and is completed with 15 stakes.

- Spunbond non-woven material is used as a covering fabric. Its feature is a longer service life, unlike polyethylene. The porous structure of the spunbond allows moisture, air and sunlight to pass through it. At the same time, the non-woven material protects plants from temperature extremes. Pockets are sewn across a fragment of the covering sheet, slightly wider than the diameter of the pipe. The arcs are brought into pockets, which allows you to firmly hold the spunbond on the frame of the greenhouse.

- Snowdrop comes with plastic clips. Peculiar latches are designed to fix the covering sheet on plastic arcs.

After removing the Snowdrop from the package, the vegetable grower receives an assembled greenhouse, the arcs of which just need to be stuck into the ground.

Dimensions and cost of factory-made greenhouses

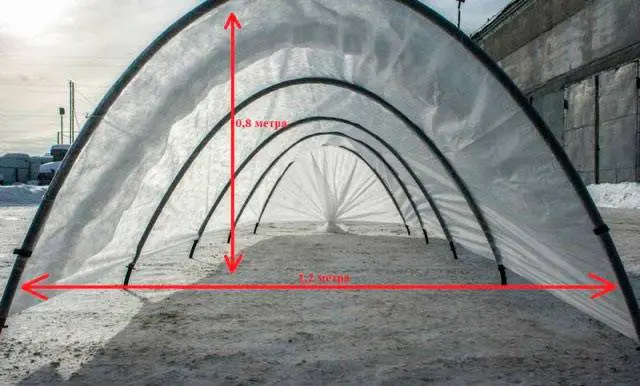

Snowdrop comes on sale in standard lengths of 3,4,6 and 8 m. Width, always fixed – 1,2 m. As for height, traditional products are limited to 0,8 m. However, there is a Snowdrop plus greenhouse model, in which the height of the arcs reaches 1,3 m.

The weight of each model depends on the dimensions, but the difference is small. Thanks to the use of lightweight materials, the weight of the finished product varies from 2,5 to 3,5 kg. For a greenhouse, the optimal density of spunbond is determined – 42 g / m2. Greenhouses Snowdrop can be produced by other manufacturers, which affects the cost of the finished product. Most often, the price ranges from 1000-1800 rubles.

Features models Podsnezhnik plus

As an improved modification of the main product, the manufacturer offers the Snowdrop plus greenhouse, which differs in its dimensions. The model is characterized by an increased height of the arcs up to 1,3 m. This does not greatly affect the convenience of caring for plants. After all, it is still impossible to enter a greenhouse with such a height. The advantage of the model is the possibility of growing tall plants. Snowdrop plus can be used for some varieties of semi-determinate tomatoes and trailing cucumbers.

The product package remains unchanged. The difference is the greater height of the arc and elongated stakes. With an increase in the dimensions of the greenhouse, the windage increases proportionally. For a strong fixation to the ground, elongated stakes are needed. The weight and compactness of the shelter in the assembled state remain almost at the same level as the standard Snowdrop.

The video shows Snowdrop plus:

The advantage of covering material for Snowdrop

Plastic film for sheltering greenhouses is gradually becoming a thing of the past due to its fragility. Usually it lasts for one season. The manufacturer decided to cover the Snowdrop greenhouse with non-woven material – spunbond.

The advantages of spunbond over film are obvious:

- The porous fabric transmits the sun’s rays well. However, at the same time it creates shading that protects the leaves of plants from burns.

- During rain, spunbond passes water through itself. Free irrigation of plantings with rainwater is carried out, plus liquid does not accumulate on the surface. In the case of the film, the formation of puddles is accompanied by large sags. In addition to the fact that polyethylene is capable of bursting, a large volume of water that has collapsed will break the delicate stems of plants.

- Spunbond is not afraid of UV rays, temperature changes and severe frosts. The resulting hole is easy to patch, which is impossible to do with the film.

With careful use and careful storage, spunbond will last at least three seasons.

Installation of a factory-made snowdrop

So, it’s time to consider the procedure for installing a factory-made Snowdrop greenhouse. There is nothing difficult in this, let’s get started:

- The greenhouse is sold in a package. Most often it is a plastic bag. Before installation, the structure is removed from the package, stretched along the entire length of the beds and the folds on the canvas are allowed to even out.

- On the broken beds, it remains only to install the structure, but if they are not there yet, you need to choose the optimal location. The beds are best placed in an unshaded area of uXNUMXbuXNUMXbthe yard, slightly blown by the winds. If the size of the site allows you to choose the best place, then it is better to place the greenhouse from south to north. From this, the sun’s rays from morning to evening will evenly heat the plants.

- Having decided on the location of the beds, proceed to the assembly of the frame. In principle, the Snowdrop is sold already assembled, you just need to insert pegs into the ends of the pipes. Starting from the extreme arc in the garden, they are stuck with stakes into the ground. The distance between the arches is determined by the covering material stretched over each section. It cannot be reduced or enlarged.

- After installing all the arcs, the covering material is spread over the skeleton. It should be slightly taut without sagging or wrinkling. On the arcs, the spunbond is fixed with plastic clips. In the future, they will provide the convenience of opening the sides of the greenhouse for plant care.

- In this photo, the Snowdrop greenhouse is depicted with the edges of the covering cloth tied at the ends. This is the final install. Spunbond at the ends of the greenhouse is tied to stakes or tied in a knot and pressed down with a load.

For further arrangement of the greenhouse, you can use a few tips. For example, the end edges of a spunbond, tied in a knot, should be pressed to the ground at an angle. This will provide an additional stretch of the covering material on the entire frame. On one side of the spunbond structure, the load is pressed to the ground, and on the other hand, the canvas will be held only by clips. Plants will be taken care of from here.

The video shows the Snowdrop:

Self-made snowdrop greenhouse

There is nothing easier than making a snowdrop greenhouse with your own hands from materials available on the farm. Any plastic pipe taken from an old water pipe and a non-woven fabric will work.

The manufacturing process is simple:

- In order for the bed to be warm, a depression of about 50 cm is dug in its place. Compost, leaves, small grass are poured into the pit, and covered with fertile soil on top.

- The plastic pipe is cut into pieces and the arcs are bent. Instead of stakes, pieces of reinforcement are used. The arcs are stuck into the ground in increments of 60–70 cm.

- The covering material can simply be laid out along the frame of the greenhouse, fixed to the pipes with purchased clips. If the house has a sewing machine, pockets for arcs can be sewn on the canvas from the stripes. Such a greenhouse will turn out like a factory model.

The canvas is pressed to the ground with any load or tied to driven stakes. On this homemade Snowdrop is ready.

Reviews

Users about the Snowdrop greenhouse leave very different reviews. Let’s get to know some of them.