Contents

The main disadvantage of plastic is that it is still not strong enough to avoid breakage or cracks. Advantage – high maintainability. Moreover, most of the products can be glued at home. But specifically, how to glue plastic in a particular product depends on the type of plastic, and there are a lot of them. Adhesive compositions for the most common types of plastics are given below.

How to choose glue for plastic

Under the name “plastic” or “plastic” materials of different properties and characteristics are hidden. Glue is selected depending on the type of plastic. Typically, the packaging of the adhesive indicates the type of plastic that can be worked with.

This can be a listing of names, abbreviations or graphic icons. Some of them are in the picture, in fact there are many more.

Selection of the type of glue depending on the type of seam and loads

In addition to the type of plastic, the adhesive must be selected taking into account the scope of the product. For seams that will be exposed bending loads are more suitable for contact adhesives. They form an elastic, well-flexible seam. When gluing, it is necessary to apply the composition to both parts, let it dry, then press and hold for a while.

For static seams, it is better to use a reaction (one and two-component) or liquid composition:

- Two-part reactive adhesives are mixed before use. In one-component, oxygen or water vapor, which are contained in the air, can be used as a reagent.

- Liquid can be based on solvents and water. Water-based for plastics are not used. Solvent based only. For bonding, the solvent must evaporate, so it is important to ensure the specified temperature conditions and good ventilation.

For load-bearing parts or for large bonding areas, look for structural compounds. They are designed for various types of loads – bending, twisting, straight lines, etc. Choose depending on the type of loads to which the seam will be subjected.

Not many compositions are suitable for gluing plastic at home. Some require special conditions (high temperatures or a special environment), others are too dangerous for health or expensive. In any case, plastic glue cannot be completely safe, so it is best to work outdoors, or at least with an open window. And don’t forget gloves, goggles and a respirator.

How to glue polystyrene

For gluing polystyrene and acrylic, it is best to dissolve shavings of the same plastic in dichloroethane. But dichloroethane releases toxic substances. It should be used only for thick-walled parts with which you are not in constant contact. It is better to work in a respirator and gloves.

For indoor use, you can use adhesive for plastic panels. Examples:

- Korapur 666. Designed for gluing materials based on wood, fiberglass, steel and aluminum sheets, plastics based on polyurethane, polystyrene and PVC.

- Акрид FS22 (ACRID FS22). Two-component methacrylic adhesive that forms a seam of high rigidity. Bonds polyurethanes, polystyrenes, acrylics, fiberglass, steel, aluminium, duralumin, artificial stone and plexiglass.

Insulation plates (polystyrene foam or extruded polystyrene foam), decor elements and stucco moldings have recently been made from polystyrene. They have their own ingredients. They are suitable for gluing plastic parts, but they are not able to carry any serious loads.

You can make homemade glue for polystyrene. Dissolve crumbs / chips of material in gasoline.

The composition should be fluid, but thick. They lubricate the parts with it, wait until the gasoline evaporates a little, press it and leave it in this state for several hours. The same composition can fill unnecessary recesses and holes.

Adhesive for PVC plastics (polyvinylchloride, PVC)

This type of plastic becomes brittle from prolonged exposure to ultraviolet light. If it began to break in your hands, you can no longer help with glue. If there are only chips or cracks, you can use the same dichloroethane with dissolved chips for repairs, but glue is safer. There are a lot of them for this type of plastic. Here are a few names:

- Quilosa SINTEX H44. Designed for welding hard PVC, as it literally melts the material. So in the cut, the junction looks like a monolith with no signs of a seam. Bonds PVC pipes for cold and hot water, sewer, window profiles, linoleum, wallboard and other PVC materials. Can be used to repair cases of household appliances.

- Cosmofen Plus for PVC. Often used to repair plastic window frames. Glue extra holes, cracks, close up the gaps between the window sill and the frame. The composition has a good filling capacity, so that sufficiently wide gaps can be sealed in two or three passes. The seam is tight, does not pass air, moisture.

Cosmofen Plus is available in clear or white. Often used to repair plastic window frames - Bailey L-6023. Adhesive for PVC pipes. Also suitable for bonding ABS plastics. Can be used for tap water, food containers, technical purposes. The connection is tight, withstands pressure up to 2,5 MPa.

- Adhesive for PVC fabrics for sticking boats, air mattresses, pools. The name is usually “PVC Glue Patch” or something like that. There are different manufacturers. Allows you to patch up gaps and holes in PVC films and fabrics.

Polyvinyl chloride-based plastics are one of the most common and almost every plastic adhesive is suitable for them. It’s just that the strength of the seam will be different and this should be taken into account when choosing. The strength of the bond with different materials or at least plastic/plastic must be stated on the data sheet or on the packaging.

For bonding ABS plastic

The most suitable adhesive for ABS (ABS) plastic is cyanoacrylate. They also glue plexiglass, PVC and polystyrene, but check each composition for compatibility. Universal reaction types of adhesives are also suitable for ABS, which glue a wide range of different materials.

- CUDO and Cosmoplast 500. These are cyanoacrylate compounds. The first is a second, with a very short setting time (from 5 to 10 seconds), the latter is just a quick action.

- Griffon B-25. For gluing/welding ABS pipes – melts the surface to which it is applied. It requires careful handling due to the pungent odor, which irritates not only the bronchi, but also the eyes.

Adhesive for ABS plastic is not such a rarity - Loctite 406. Adhesive for plastics, metals and elastomeric materials. Including for ABS plastic. Can be used to join different types of plastics.

- SikaFast®-555 L05. It is a two-component reactive adhesive for flexible joints under continuous stress. Used in the automotive industry. You can glue glass, plastics, metals.

- TEROSON PU 9225 SF ME. Fast two-component polyurethane adhesive for the repair of plastic parts. Also suitable for ABS plastic. This is another glue for repairing automotive plastics: interior parts, bumpers. Can be dyed after polymerization.

Glue TEROSON PU 9225 SF for the repair of plastic parts. It is also used for gluing autoplastics

In general, this type of plastic is characterized by brittleness under compressive loads. The seam, as a rule, is also fragile. For reliability, reinforcement is required. An example of reinforcement for domestic conditions is the reinforcement of a seam with a strip of fiberglass impregnated with a suitable composition. The strip is laid on the back side over the already frozen seam.

Adhesive for polyurethane

Polyurethane is more commonly found in foamed form. Moldings and decorative elements are made from it. There are special formulations for these products. There are sometimes products made of sheet or cast polyurethane. Most two-component reactive compounds can be used with them, but check the description for compatibility with this type of plastic.

There are few options that are designed specifically for this type of polymer. One of them is glue for polyurethane “Uranus”. They can glue polyurethane with other plastics (PVC, ABC). Suitable for repairing artificial leather shoes. Forms an elastic seam, can be glued in a cold and hot way.

In case of cold gluing, grease both glued surfaces with glue, hold for 1-2 minutes, apply and press for 5-6 hours. For hot gluing, spread glue on both parts, heat up to 90°C, press for 1-2 minutes. Can be used after 4 hours. Most often used for repairing shoes, it can be used to repair air mattresses, circles, slides, tents and other similar products.

If you need a solid hard seam, look among the universal compositions. It can be a mounting, structural adhesive. Most often – reaction based on polyurethane. A couple of examples:

- SikaBond-T2. A one-component polyurethane adhesive that adheres well to various types of materials, both smooth and porous. Glues all types of plastic, including polyurethane.

Any of them is suitable for gluing automotive plastics. Difference in curing speed - Wurth replast easy. Two component polyurethane adhesive. Used to repair plastic parts in cars, trucks, motorcycles (auto plastics). Suitable for gluing bumpers, headlights, grilles, trim parts. Resistant to many types of solvents, works with almost all types of plastics.

There are many adhesives based on polyurethane. They can be with different properties – transparent and opaque, waterproofing, with fixation to porous and smooth substrates (including anodized aluminum, brick, etc.). Since the basis of the compositions is polyurethane, it glues the plastic of the same name by 100%. It is only necessary to choose the required properties of the seam – elastic or rigid, waterproof or acid-resistant, with increased resistance to high temperatures or other properties. There are really a lot of compositions, so there is plenty to choose from.

How to glue polyethylene, silicone and polypropylene

Polyethylene is one of the most commonly used plastics in everyday life. Polypropylene is less common, and silicone is beginning to compete with polyethylene. But gluing these types of plastics is not easy. It’s all about their inertness – they do not react with most substances. This is what makes them so popular for home use. But, due to the same inertness, it is very difficult to find a suitable glue. There are only single copies. Here are all the names we found:

- TYTAN CLASSIC FIX. A general purpose adhesive that has high adhesion to hard plastics including polyethylene and polypropylene. Gives an elastic seam resistant to water. Seizes quickly, does not freeze.

- Korapren 88; Körapren 82 2К. Glue one of the subspecies of polyethylene – CSPE chlorosulfonated polyethylene, synthetic rubber, PVC. Also suitable for fabrics or woven fabrics made from the materials listed. It can be used for gluing air mattresses, boats, slides and other similar products. 82 2K has a higher initial setting speed.

Even for polyethylene, silicone and polypropylene, there are several types of glue - Glue Temonten “Duct tape”. After drying, it leaves a permanently sticky film on the surface. Provides adhesion to most building materials, wood, glass, fabrics, inert surfaces, including PP polyethylene, PE polypropylene, PPE foam.

- LOCTITE® AA 303. Suitable for gluing different types of polyethylene (LDPE and HDPE), polypropylene. The seam has a high resistance to impact loads.

LOCTITE® AA 303 is a highly resistant polyethylene adhesive. Glues, if not tightly, then very firmly - Permabond 2050. It is an elastic cyanoacrylate adhesive with high peel strength. Paired with Permabond Polyolefin Primer, it can be used to bond polyethylene, silicone and polypropylene.

- Permabond C2011. Cyanoacrylate gel adhesive for bonding to porous materials, for vertical or inverted bonding. Permabond Polyolefin Primer can also be used on PP, PE, silicone, provided that Permabond Polyolefin Primer is used first.

- Scotch-Weld DP-8005. Two-component acrylic-based adhesive that can bond “low reactive” materials, including polyethylene, polypropylene, silicone. Moreover, they can be interconnected, glued to other materials with other characteristics.

- MONTAGEFIX-F. Mounting adhesive for gluing polyethylene films and membranes, aluminum foil and other plastic films. It is used in construction to create a hermetic vapor barrier. Does not run when applied to vertical surfaces.

Description of adhesive for PVC film MontageFix-F - Aerosol 3M 90 Scotch-Weld. Adhesive composition in the form of a spray for gluing rubber, wood, fabrics, polyethylene, glass, laminates, flexible PVC. It has a fast initial setting time and super strong adhesion.

As you can see, you can find compositions for gluing even such complex materials to any type of surface. The bad news is that almost all of them are made to order. So you have to wait at least a couple of weeks for delivery.

How to seal securely: ways to reinforce the glue line

Some seams have a significant load. There are compositions that replace welding, riveting and other types of mechanical connections. They dissolve the top layer of plastic on the parts to be joined, so that there is no seam at the junction, but a monolith is formed. But not all adhesives work that way. To increase reliability when using “ordinary glue”, the gluing place is reinforced:

- In thick plastic, holes can be drilled along the crack or edges of the parts to be glued. “Sew” the edges with metal wire. To make such “art” less noticeable, we warm up the wire by melting it into plastic.

- The seam of thin-walled parts can be reinforced with a strip of fiberglass fabric. It is glued from the back along the seam after the glue has dried. Use the same composition as for the connection.

For seams with less stress, you can use a strip of fiberglass - In plastics with a low melting point, the adhesive line can be strengthened by soldering the wire. You can make a bracket out of wire or use staples for a stapler. The bracket is placed perpendicular to the seam, the back is heated with a soldering iron until the legs are immersed in plastic. You can also bend the wire in a zigzag and immerse this “snake” in sections in molten plastic. In any case, we heat the metal with a soldering iron until the plastic begins to melt.

An example of fastening a seam of hard thick-walled plastic using metal staples for a stapler

After such reinforcement, well-marked irregularities remain. The appearance can be improved by sanding the surface. If necessary, you can polish. Sanding plastic will require medium to fine grit sandpaper (100-150 for smoothing and 180-240 for sanding). For polishing, you can use GOI paste applied to felt or other soft material.

How to glue plastic with other materials

It is often necessary to bond plastics to other types of materials. For these tasks, repair, universal, assembly or structural types of compositions are selected. They are designed for bonding materials of various characteristics.

- Quilosa Bunitex P-55. Glues plastic (especially PVC) with rubber, wood, cork, paper.

How to glue plastic and other materials: structural, universal, assembly compounds. One example is Quilosa Bunitex P-55 - Quilosa Fix Express Mounting. Bonds PVC with all other materials, including metal, glass.

- Den Braven Zwaluw Montagefix-PU. Universal adhesive for outdoor and indoor use. Bonds wood, chipboard, metal, stone, concrete to hard plastics.

Compositions of different companies, with different properties, setting and curing speeds - Soudal Cyanofix 84 А. Cyanoacrylate contact adhesive for bonding plastic, paper, cardboard, ceramics, porcelain, glass. Not suitable for bonding metals.

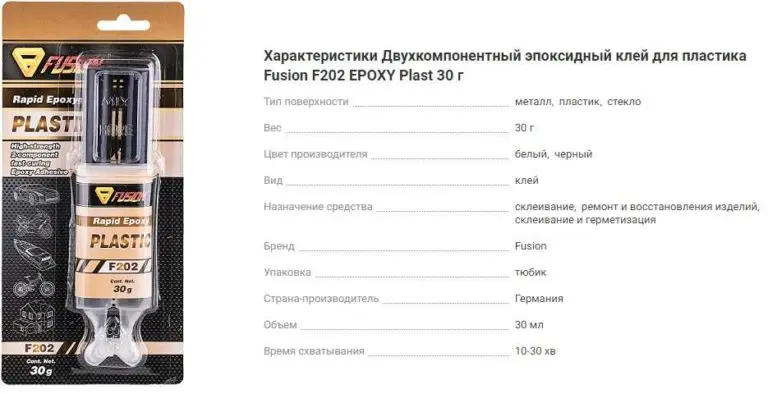

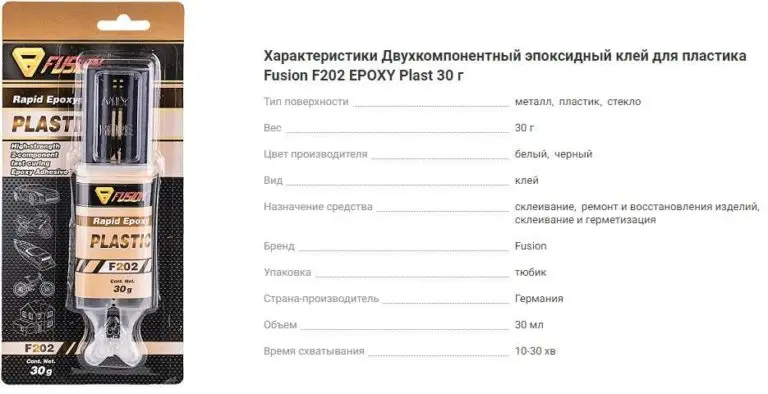

- Fusion F202 EPOXY Plast. Two-component epoxy adhesive for plastic, glass, ceramics, porcelain. Can be used to fill holes and defects. It is applied to repair of details of the car, motorcycle, bicycle. Resistant to UV, solvents, waterproof. Does not shrink, does not deform.

Adhesive for the repair and restoration of plastic parts of a car, motorcycle, bicycle

There are many compounds for gluing plastic to various materials. From the whole set, you should choose based on the properties that are required: resistance to light, the possibility of coloring, water resistance, elasticity. They are not always combined in the same composition.