Due to the rising cost and falling quality of store-bought liquor, home-brewing is gaining popularity. The first thing that is required for this is a moonshine still. For various reasons, not everyone can make a distiller; most beginner distillers buy devices. This article will help you decide which device is right for you. Separately, we will consider methods for checking sellers before buying.

1. Functional purpose. The first and most important criterion. On sale you can find the following types of moonshine stills:

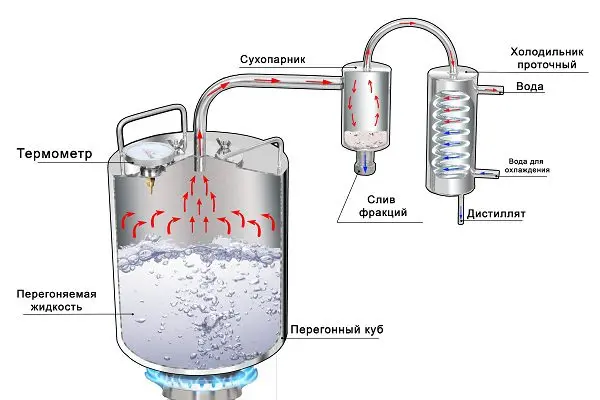

Classic distiller – consists of two interconnected parts: a distillation cube and a refrigerator (coil). For most ordinary people, it is this design that is associated with moonshine, because due to the ease of manufacture it has become widespread, especially in rural areas.

Principle of operation: first, the mash in a cube is heated to the boiling point of alcohol, then the steam is cooled (condensed) in a coil. It turns out a distillate – moonshine with a maximum strength of 75-80 degrees at the outlet (in the stream). But even theoretically, distillation cannot produce pure alcohol; there will always be other impurities in the drink. On the one hand, this is good for preserving aroma and taste, on the other hand, along with the “necessary” impurities, harmful substances also enter moonshine: methyl alcohol, acetone, acetaldehyde, fusel oils, etc.

Advantages of the distiller: low cost, ease of assembly, distillation and maintenance. The classic moonshine still preserves the aroma and taste of the raw materials better than other designs: grains, fruits, berries. Suitable for the preparation of analogues of such drinks as whiskey, cognac, calvados, rum.

Disadvantages: to obtain normal quality, moonshine must be distilled 2-3 times with the division of the output into fractions – the so-called “heads”, “body” and “tails”. Grain and sugar distillates are preferably further refined between distillations, for example with charcoal. All this requires time and energy (for heating and cooling).

Moonshine still with dryer – an ordinary distiller, in which another module is installed between the distillation cube and the coil – a dry steamer (aka a sump). This is an empty container of a certain volume, connected from above by tubes to a coil and a cube.

The principle of operation of the steamer is based on the fact that the boiling point of ethyl alcohol is higher than that of many dangerous substances. Theoretically, getting into the steamer, harmful impurities condense there, but do not boil again, since the thermal energy is spent on the evaporation of ethyl alcohol.

In practice, the pry bar does not cut off as many harmful substances as sellers like to talk about it. Despite this, a moonshine still with a dry steamer has two advantages: protection against splashing (hot mash gets into the coil when overheated) and the ability to flavor moonshine, for example, with lemon (orange) zest, berries and herbs, simply by putting these substances in a dry steamer. The rest of the design is no different from the classic distiller.

To protect against spray and aromatization, one dry steamer is enough. Installing two or more tanks is a marketing ploy and does not improve quality. In some cases, it is possible to increase the fortress, but this does not mean that moonshine has become cleaner. Even if you connect 12-20 cans (such models are on sale), harmful impurities will remain. Moonshine will be stronger at the exit (higher degrees), but not cleaner.

Alambic – This is a classic distiller (usually copper), in which the upper part of the distillation cube is made in the form of a dome. It is used in the traditional technology of making cognacs and whiskey. In terms of the quality of the drink, it has no advantages over other designs; only copper models retain the organoleptic quality of the drink better.

Almost all alambicas are handmade abroad, so their cost can be many times higher than the price of other devices. Usually, for the money spent on alambik, you can buy a mini distillery with a high degree of automation.

Advantages: due to its beautiful appearance, this is the best version of the moonshine still as a gift or as an exhibit for decorating the distiller’s house, ancient traditions are respected.

Disadvantages: very high cost, after several distillations, the alambic tarnishes, losing its original luster.

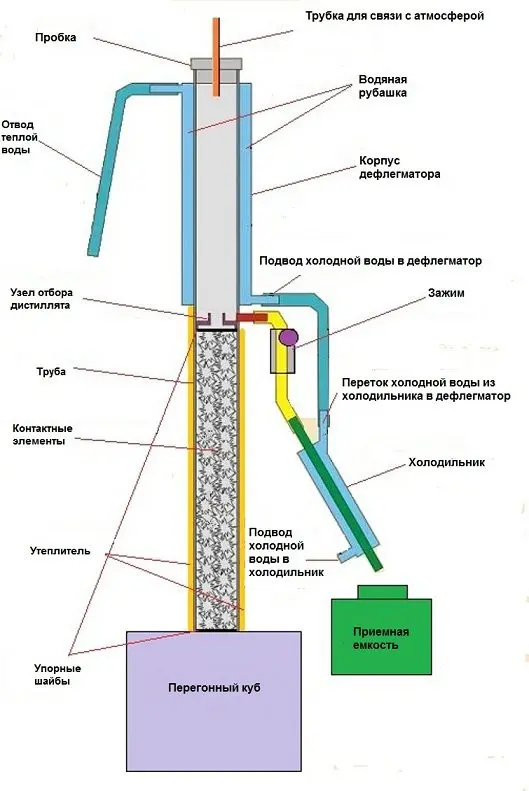

beer column – moonshine, in which the alcohol vapor cooling module is made in the form of a vertical pipe with a reflux condenser (reflux condenser) installed on top, which separates the liquid into fractions during distillation. It can be used to prepare any drinks: both ordinary sugar moonshine, and for “noble” distillates (cognac, whiskey, chacha), while retaining the aroma.

Advantages: versatility of use, good purification from harmful impurities while preserving the aroma of raw materials, average price, relative ease of operation.

Disadvantages: it is impossible to get all the alcohol contained in the mash without degrading the quality, the losses are 45-70% of the total volume, that is, from 2 liters of absolute alcohol in the mash, an average of 1 liter of high-quality distillate will come out. The design turns out to be overall (in height), it is not always possible to install it in an apartment.

Distillation column – This is a vertical cylindrical vessel, equipped inside with heat and mass transfer devices (plates or nozzles) for separating a liquid into fractions that have a close boiling point. If necessary, it can be used as a conventional distiller or beer column.

Rectification separates harmful impurities much better than distillation, theoretically you can get pure alcohol (without foreign smell and taste) up to 96% of the fortress, but the result on home distillation columns is usually more modest.

The advantages of a distillation column: the only way to qualitatively separate impurities, obtaining almost pure alcohol from any mash. Does not require double or triple distillation. In the course of work there is no specific smell.

Disadvantages: during rectification, the aroma and taste of the feedstock are lost, the column is more difficult to maintain and operate than a conventional apparatus. Due to the large height dimensions, there may be problems with a suitable installation location. The cost of distillation equipment (in addition to the column itself, at least temperature sensors are also needed) is usually higher than that of classical distillers (except for alambicas).

2. The volume of the cube, power, dimensions. These parameters depend on how often you plan to drive moonshine. General rule: other things being equal, the more productive the moonshine is, the more expensive, heavier and larger it is.

First of all, you need to decide on the volume of the cube. During distillation, any apparatus is allowed to fill up to 80% of the volume. For example, if the cube is 15 liters, then for safety reasons no more than 12 liters of mash are distilled at a time. This is not as little as it might seem, because dividing the mash into two distillations is much more practical than purchasing one large apparatus, especially if you drive moonshine no more than 1-2 times a week.

The capacity of the cooler should correspond to the volume of the cube – be equivalent or higher with a margin in case you plan to connect a larger cube in the future. You need to find out the performance of the device from the manufacturer, being interested not only in the number of liters per hour, but also in the maximum possible volume of the connected cube, degrees of heating and recommended cooling intensity.

When buying a beer or distillation column, you should remember that their height usually exceeds 1 meter. Taking into account the fact that the device has to be installed on a stove, there may not be enough free height to the ceiling or to the hood.

3. Material. Craftsmen made moonshine from aluminum, but this is not the most suitable material, because it affects the taste and releases harmful substances into the drink. Modern manufacturers use two inert (not reacting with alcohol) metals – stainless steel and copper.

The advantage of stainless steel is its low cost, long service life and reliability of the device, which requires almost no maintenance (only rinsing and cleaning). The main thing is that the stainless steel complies with GOST for the food industry. This document must be shown by the seller or manufacturer. The thickness is not less than 2 mm, otherwise, with strong heating, the mash may burn.

The only material (other than glass) that does not affect the organoleptic properties of the distillate in any way is copper. In addition, due to its high thermal conductivity, copper quickly heats up and cools down, which reduces the time spent on distillation. The disadvantage is that copper moonshine stills are more expensive and are used to produce elite alcohol: whiskey, cognac, tequila, calvados.

Any turbidity of moonshine and third-party tastes in copper devices appear only due to poor maintenance of the device and have nothing to do with the material itself. According to GOST, copper is allowed to be used in the production of alcohol.

4. Design features. Depending on the situation, both simplify and complicate the process of moonshine brewing. For example, if all the modules of the device are collapsible, they are easier to clean. The presence of drain taps on the cube and on the steamer also simplifies maintenance. The neck of the distillation cube should be wide enough so that you can easily put your hand inside, otherwise it will be problematic to remove the scale.

If the device does not fit into the height dimensions, you can buy a cube with built-in heating elements and not put it on the stove, saving space. But during distillation, the heating element must be immersed in the mash, otherwise it will burn out. As a moonshine still for summer cottages, where there are problems with water supply, devices that do not require running water are better suited, such are on sale.

Each modern model must necessarily be equipped with at least one thermometer, which can be used to navigate when separating distillate into fractions.

The presence of automation, on the one hand, simplifies the process, on the other hand, complicates maintenance, because even if one controller fails, often the entire device ceases to function.

How to buy moonshine still

5. Checking documents. Choosing a suitable model is only half the battle, it is much more important to find a normal seller and check the product documentation. This is very important when buying a moonshine still over the Internet, where there are many businessmen who want to profit from inexperienced moonshiners.

Unfortunately, cases of fraud and the sale of unsuitable devices of dubious design have become commonplace. Reviews on the forums and the advice of the “specialists” living there are paid for in 90% of cases, you should not be guided by them.

If possible, purchase a moonshine in your locality in a stationary store so that in case of problems you can consult or return the goods. But often a distiller or distillation column is chosen on the Internet. In this case, I advise you to pay attention to the following aspects:

- Check seller registration. The methodology varies by country. For example, in Russia, you can check the OGRN (Main State Registration Number) and OGRNIP (Main State Registration Number) on the website of the Federal Tax Service (FTS). If there is no data or they do not match those on the seller’s website, you have a scammer in front of you.

- It is desirable that the seller has a real physical address where it can be found. A direct landline phone number (not 8800), complete data on the site and the availability of a support service that responds quickly at the stated time are an indirect confirmation of honesty.

- The description of the moonshine still must be complete: all parts and assemblies are listed, the materials from which they are made are named, all technical characteristics are indicated in numbers or ranges under specific operating conditions. At the first request, the seller must name the manufacturer of the equipment, its physical address and contact details.

- Familiarize yourself with the instructions and certificates for the goods. At the request of the buyer, any normal store provides instructions in electronic or paper form. The document itself should contain not only complete information about the configuration and assembly, but also descriptions of various modes of operation, including safety precautions and rules for caring for equipment. The more detailed everything is, the better. A separate chapter is the terms of warranty service. The provided quality certificates also need to be checked; in Russia, for this, it is enough to enter the number on the website of the Unified Register of Certificates of Conformity. Only if all the documents are in order, you can make a purchase.