Contents

Each owner needs a barn on his own plot, but you don’t always want to bear the high costs of building it. It will be easier and cheaper to build a utility block after the construction of a residential building, since there are always extra materials. But what to do if a person has nothing on his hands, but a utility room is still necessary? Now we will look at what you can build a barn with your own hands cheaply and quickly.

Decide on the purpose of the barn

Before you build a cheap barn, you need to decide on a number of important issues. The design of the hozblok will depend on this, and what will you build it from:

- When erecting even the most inexpensive structure, ask yourself why you need this barn. The answer according to the principle: “It will come in handy for the future” or “To keep up with the neighbors” will not work. You need to know the purpose of the barn. Suppose, if you need a woodcutter, then it will be cheaper to assemble a frame hozblok from boards and timber. To keep animals, you need a strong and warm building. From cheap material here it is better to give preference to foam concrete.

- The amount of expenses depends on the dimensions of the hozblok. If the built barn will be used to keep poultry or animals, you need to roughly calculate how many livestock will live in the room.

- It will be possible to build a barn cheaply only on your own. If it is supposed to use the services of hired builders, then about half of the money will go out of the allocated budget to pay for the work. You also need to buy the right material. Often household blocks are built from used bricks or cinder blocks. They even use old lumber, which is sometimes sold by subsidiary farms after the buildings are dismantled. From cheap new materials for walls, foam block or wood concrete can be distinguished.

Having decided on all these issues, you can already begin to calculate the budget for future construction.

Cheap shed options

Now we will consider several options for how to build a barn with our own hands so that it is cheaper for the owner.

Frame shed – cheap and fast

The first place among cheap sheds should rightfully be given to the frame structure. It will not be possible to build anything faster than such a utility block, and even a person without building experience can do all the work on his own.

Let’s get acquainted with how the order of construction of the hozblok looks like:

- Before starting construction, you need to make a drawing of the barn. Guided by the scheme, mark the site. The site is cleared of debris and vegetation, after which an embankment about 15 cm thick is made of gravel, crushed stone or screenings.

- Frame sheds are usually placed on a column foundation, but our goal is to build cheaply and quickly. This means that the support racks of the frame themselves will serve as the basis. To do this, take a beam with a section of 100×100 mm and one end of all the pillars is lubricated with bitumen. You need to process a section about 70 cm long. Two layers of roofing material are wound on top of the hot bitumen.

- Adhering to the markup, holes 80 cm deep are dug around the perimeter of the future building. A layer of crushed stone or gravel 15 cm thick is poured onto the bottom. Racks are inserted into each hole, aligned vertically in level, and then poured with concrete mortar. To get a shed roof on a frame shed, the front pillars are made 60 cm higher. It is optimal to install pillars on the front side of the utility block with a height of 3 m, and the rear – 2,4 m.

- Further, a horizontal strapping of timber is nailed from above and below. For the rigidity of the frame, you need to make a couple more intermediate strappings.

- For the manufacture of a single-pitched roof, floor beams are attached to the timber of the upper trim of the frame in increments of 60 cm. To do this, use a board with a section of 50×100 mm. Along the length of the beams, they must protrude beyond the boundaries of the frame on both sides by at least 50 cm. The formed roof overhang will protect the walls from rain.

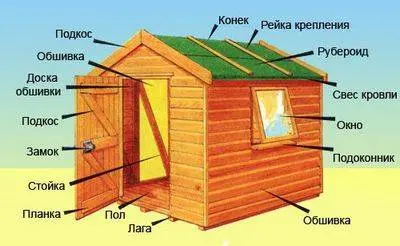

- The shedding of frame sheds is usually done with a wooden board or clapboard. Moreover, they can be nailed vertically or horizontally. The method of fastening the skin is shown in the photo. The board is nailed with an overlap to avoid the formation of cracks. With the cheapest version of the frame shed for wall cladding, the use of a slab is allowed.

- Now it remains to cover the finished hozblok. The cheapest roofing material is slate or roofing material. First, a crate is nailed to the floor beams. For roofing material, it is made solid from plywood or OSB. A board 25 mm thick is nailed under the slate in steps of 40–50 cm. Roofing is used as waterproofing.

The video shows the manufacture of the crate for the roof:

Rims - The floor inside the frame hozblok is laid from a board or OSB boards. The ceiling is lined with similar materials. For the winter shed, all the cladding elements are made double, and thermal insulation is laid in the voids. You can use mineral wool, and cheaper – sawdust.

The frame barn will last at least 10 years. During this time, maybe the owner will be able to save money for a more serious building.

In the video, an example of the construction of a frame barn:

Hozblok from corrugated board

To build not only a cheap, but also a beautiful hozblok will turn out from corrugated board. The material is inexpensive and very light in addition will last for many years. The only disadvantage of corrugated board is its weak rigidity. Before sheathing the walls, the frame of the barn will have to be reinforced with additional jibs and lintels.

In fact, a corrugated board hozblok is an ordinary frame shed. Only the lining material is different. The frame is assembled from a bar, but it is better to give preference to a profile pipe. The costs will not be much more, but once having built a metal structure, it will be enough for the owner for life. The profile frame is assembled by welding. Sometimes craftsmen fasten the elements with a bolted connection.

The corrugated board is fixed with galvanized self-tapping screws with a rubber washer. When sheathing walls, it becomes necessary to trim the sheets. It is better to do this with metal shears. If not, you can use a hand tool. But with such scissors it is easy to cut the corrugated board across the waves. It is difficult to do this along, since the stiffening ribs do not allow the sheet to bend.

You can use a grinder to cut sheets, but the abrasive wheel burns the protective coating of the profiled sheet. Over time, this area will begin to rust. If there is no other way out, you can cut the sheet with a grinder, and then it will be easier to cut the burned edge with scissors. Alternatively, the cut point can be hidden under another sheet, because the laying is still done with an overlap. At the corners of the shed, around the window and door opening, the cut edge of the corrugated board can be hidden under the additional elements.

Reliable and inexpensive barn for animals and poultry

If you need to build a barn for keeping poultry or animals cheaply and quickly, then it is better not to find foam blocks of material. Of course, a hozblok will cost more than a frame structure, but it will last for many decades. Moreover, a foam block shed is great for winter use.

The construction of the barn is carried out in the following sequence:

- A barn made of foam blocks is considered a capital building. Here you need to seriously approach the drafting and development of drawings. This will help to accurately calculate the required amount of material.

- Construction begins with marking the site for the strip foundation. Further actions involve digging a trench up to 80 cm deep. The width of the concrete tape is made 5–10 cm more than the thickness of the wall.

- Formwork is installed around the trench. The bottom is covered with a 20 cm layer of expanded clay or crushed stone with sand. Now this pillow and the walls of the trench are covered with roofing material so that the liquid solution does not soak into the ground.

- Inside the trench, a box-shaped reinforcing frame is knitted from steel rods. It is optimal to use reinforcement with a thickness of 12 mm for this. When the frame is ready, the trench is poured with concrete mortar with the addition of crushed stone. In height, the tape should protrude from the ground by at least 10 cm.

- After about a month, the concrete tape will gain its strength, after which you can begin to build walls. First, the foundation is covered with two layers of roofing material. The laying of foam blocks begins from the corners, gradually moving to the sides. As a solution, it is better to use a special adhesive mixture. It is sold in any hardware store. In the worst case, concrete mortar is also suitable.

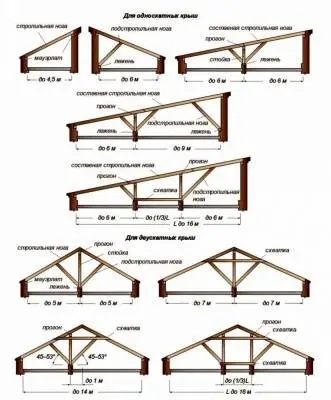

- When all the walls are built, the turn comes up to the roof. On such a shed, you can install a single or gable roof. The first option is simpler and cheaper, and the second roof design allows you to organize attic storage space.

- The foam block is considered a soft material. In order to properly distribute the load from any roof structure, a mauerlat from a bar is laid on the walls. Floor beams are nailed on top, and then a truss system of a shed or gable roof is installed.

It is desirable to choose a quality roofing for a barn made of foam blocks. From inexpensive materials, slate or corrugated board is suitable. From what to make the floor inside the barn depends on who will live in it. It is better to send boards to goats. For a bird, a clay floor with sawdust or straw is suitable. Pigs will have to pour a concrete screed, but it is desirable to lay waterproofing and insulation under it. And in the corral where the pigs will sleep, you need to lay the boards.

Conclusion

To truly build a cheap barn, you must first take a closer look at what material is at hand. After that, you can start with the choice of the type of building.