Contents

When the frame of the greenhouse is made of square or rectangular tubes, it is very reliable and has a long service life. This article will discuss how to bend a profile pipe so that the arched structure for your greenhouse turns out to be correct, reliable, and inexpensive.

How to make a square arc

Due to the fact that the metal structure is much thinner compared to wood, there is more natural light in the greenhouse. Also, this material is more technologically advanced. Being engaged in the construction of an arched greenhouse, the profile must be bent. It bends for an arch, going in a vertical way from the base up, and in the middle, in an arcuate way. For example, if you choose a Mitlider greenhouse, the strength of the frame will be ensured by connecting the racks and beams. In domed greenhouses, the structures consist of polygonal frames (aluminum / metal), but it is quite difficult to assemble them yourself.

The frame material itself is selected “under the design” of the entire structure and its dimensions. If you are going to build an arched plan greenhouse, the frame of which is made of metal, and not drywall, prepare:

- flexible rods (for semi-arcs) – one and a half meters long, in the amount of 12 pieces;

- for a building with a height of 1.8 m – 10 pieces of rods, the length of which is 2 meters and a diameter of 30 millimeters;

- it is necessary to start making a frame in order to determine the holes for the rods, sometimes it is necessary to bend a square pipe, in which the section is 20 by 20, and the diameter will be three meters.

You will need these tools:

- bending machine;

- shaped pipes;

- tape measure, simple pencil;

- Bulgarian;

- welding.

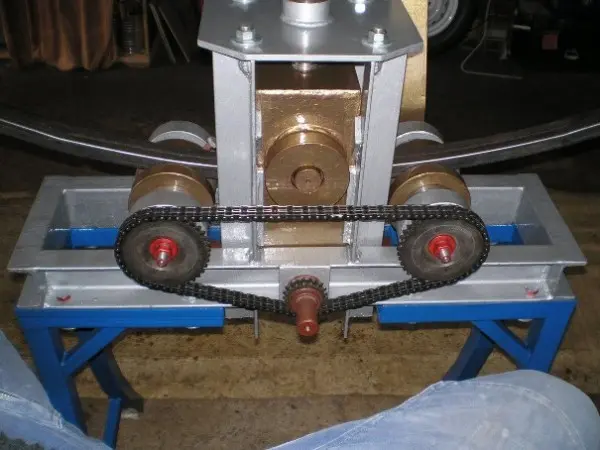

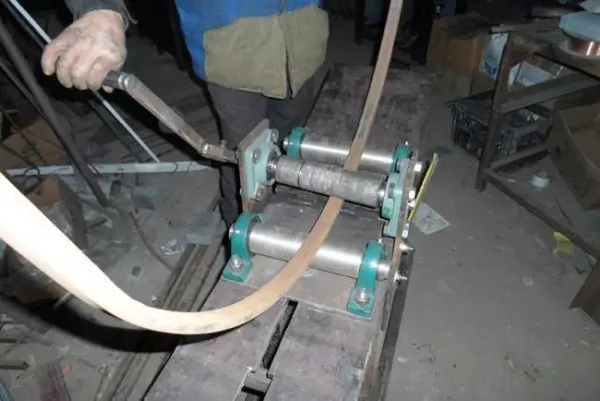

You can make a bending machine yourself, it is actually necessary to bend a profile pipe on it. Scroll it with the handle. It will take a lot of effort, even when the wall thickness of the material is about two millimeters, because this is not like laying down drywall! If you do not have a machine, you can bend it with your hands. Fasten the pipes running in parallel. Draw an arc of the desired radius directly on the ground, attach the product and bend it so that it becomes exactly the same as in the drawing. The next arc must be bent according to the pattern of the first.

The pipe must be cut in advance into equal parts with the help of a grinder, and then bend according to the pattern. In those places where there were cuts, process with spot welding. Lightweight and strong profile is easy enough to connect with the planes. In addition, it is able to withstand a fairly large transverse load.

Using a tube bender

Everyone who has tried to bend a profile pipe is aware that this is very difficult. Much easier and easier to work with drywall, but not in this case! Here to help – a special pipe bending machine or a hand-made method. Also one of the ways is fire. One part of the pipe is heated, then with the help of a lever, at a certain angle, it is bent. The disadvantages include the appearance (on completion) – rather unaesthetic and the fact that it will take a lot of physical effort, because this is not drywall!

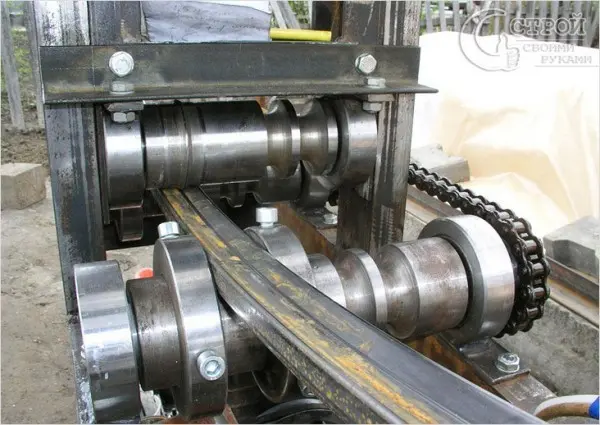

Of course, with the help of a pipe bending machine, you can bend the pipe much more accurately, faster and easier. Holding on to the handle, the profile stretches along the rollers of the machine, while the other of them presses down on the material, which deforms it. It is much more “pleasant” to bend a product in this way, when it passes through a pipe bender, it turns into an arch, and of the radius that was given to it. Using a manual machine, products can be bent to heat the greenhouse during the cold season.

Make a pipe bender. You will need:

- 3 pieces of roller;

- a special bracket with a clamping axis and a lead screw;

- metal table;

- template and blank;

- steel pipes, 0.7-1.5 cm in diameter;

- channel and welding;

- concrete mortar.

Bending methods

You can bend the pipe for the greenhouse in a cold or hot way. Both options are provided. If you heat it with a gas burner, the plasticity will be much higher. But if the pipe has a small cross section, it is already easy to bend it, without exposure to high temperatures. Pipes with thin walls are plastic and easy to bend. There are no specific recommendations regarding the heating of materials, with the exception of a pipe whose diameter is more than one hundred millimeters. But if the pipe is square or rectangular, you need to work with them a little differently.

If the profile height is less than ten millimeters, it must be cold-bent. If the height is from forty millimeters, then heating is indispensable. Regarding bending the material with a height of ten to forty millimeters, everyone decides for himself how it is convenient for anyone and in what way, because this is not drywall, you still need to bend it! If you have a special tool for bending the pipe, then you can do without heating.

Video “How to make a pipe bender and bend a profile pipe with it”

A lot of necessary information about the pipe bender, in order to eventually make a frame for the greenhouse.

Cold method

If the profile height is up to ten millimeters, it must be filled. You can use sand, rosin or a tightly coiled spring for this. You can do it yourself, for which you will need: a bending plate, a vice and a mandrel, a bend profile (you can either make it yourself or buy it in a store).

with heating

Material that does not lend itself to the cold method must be heated at high temperatures. The pipe is pre-filled with sand for even bending and quality of work. You will definitely need canvas mittens. Trimmings (logs) will be needed for a pyramidal plug, ten times longer than the base. The very area of the base of the cork should be twice the size of the hole that it will close. Try on how the corks fit, then on one make grooves of a longitudinal shape, on each side. On the future bend, you need to anneal the workpiece.

Prepare a filler from building medium-grained sand (it must be thoroughly sieved, several times through a sieve with cells of different diameters, first 2 mm, then 0.7 mm). Next, the filler must be heated when exposed to a temperature of 150 degrees Celsius. Plug one end of the pipe with a plug, put a funnel on the other. The workpiece must be installed perpendicular to the ground, or at an angle, it all depends on the size. And fill with sand through the funnel. In order for it to compact, tap the pipe with a mallet. A dull sound means fullness.

Then close with a second cork the end of the pipe through which the sand was poured. Secure the product in a pipe clamp or vise. The welded joint should be on the side. Very carefully give the desired shape to the pipe. In one move, bend it not sharply, but always in a vertical or only in a horizontal position. Everything worked out. Corks can be knocked out (burned out) and sand poured out, the material for the greenhouse frame is ready!

Video “How a pipe bender works”

In this video you can see the sequence of actions that must be carried out in order to bend the pipe.