Contents

Snowy winters, along with joy, bring a lot of worries related to snow removal. Cleaning a large area with a shovel is quite difficult. Craftsmen immediately found a way out and invented a huge number of homemade products. The advantage of this technique lies in the lower cost compared to factory counterparts. Now we will look at how to make a snow blower with your own hands from the spare parts available on the farm.

How to make a snow blower with your own hands

Snow blower manufacturing process

The most efficient do-it-yourself homemade snow blower for your home will turn out if you equip it with an auger mechanism. Most all factory-made snow blowers have a similar design. The principle of operation of the equipment is to capture the snow with rotating spiral blades. The snow blower auger consists of two spirals on the sides, and metal blades are welded between them in the center of the shaft. They throw snow into the outlet sleeve. The snow blower is connected to the traction unit itself through a belt drive.

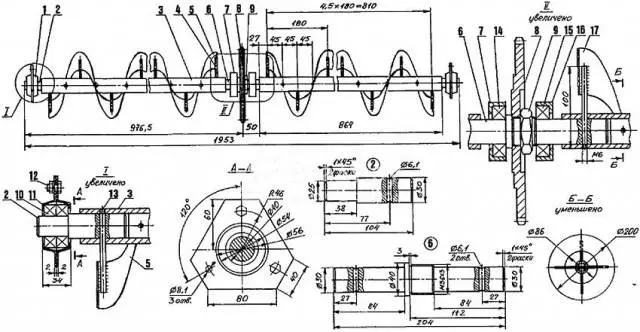

The assembly of a rotary snow blower begins with the manufacture of an auger. First you need to find material for spiral knives. To get four rings with a diameter of 28 cm, you need to find 1,5 m of a conveyor belt 1 cm thick. Knives for the auger are cut out, leaving petals inside the ring. They are needed for attachment to the working shaft – the rotor. As a result, the harvesting of the auger knives should be obtained, as in the presented photo.

Sheet steel auger knives will be stronger. In this case, eight half-rings are cut out, which are then welded with a spiral. You can go the other way. Four disks are cut out of sheet steel. On the side, each ring is cut with a grinder, after which the edges are pulled in opposite directions.

For self-manufacturing of the auger, it is better to use the drawings. If you look at the presented diagram, it will immediately become clear that the spiral knives consist of two parts, and between them there is a shovel for throwing snow into the discharge sleeve.

The working shaft of the snow blower auger is made of a steel tube with a diameter of 20 mm and a length of 800 mm. Bearings No. 203 or 205 are mounted on both ends. But they cannot be stuffed onto the pipe. For bearings, you will have to machine two trunnions. And one of them is made longer. A belt drive pulley is then mounted on this trunnion, from which the rotor will rotate.

Two metal blades are welded parallel to each other in the center of the pipe. The steel blades of the auger are simply welded to the pipe. If they were made from a conveyor belt, then the mounting lugs are first fixed to the shaft by welding, and the knives are already bolted to them.

Now it remains to assemble the body of the snow blower and insert the finished auger inside. For these works you will need sheet steel 2 mm thick. Fragments of the future body of the snow blower are cut out with a grinder, after which they are welded into a single structure. From the inside, in the center of the side elements of the housing, the bearing seats are fixed, after which the auger is inserted into its permanent place. A belt drive pulley is mounted on a trunnion protruding on one side. The body of the snow blower itself is mounted on skis, and a steel strip of a stationary knife is bolted from below. This element will cut the layers of snow.

The video shows a homemade auger snowplow:

For the full implementation of this project, it remains to choose a traction unit that will power the rotary snow blower.

Re-equipment of a walk-behind tractor into an auger snow blower

The easiest way is to assemble a snowplow with your own hands if you have a working walk-behind tractor. To implement this project, you do not need to look for additional spare parts. The rotary snow blower is already assembled. There is a traction device. Now it remains to couple these two units, make a belt drive and the snowplow is ready.

Depending on the brand of the walk-behind tractor, the snow plow hitch is attached to the bracket on the front or rear of the frame. In the second option, the steering wheel will have to be turned 1800. The snow thrower will travel at reverse speed. In the case of a front mounted hitch, the walk-behind tractor rides in first gear at a speed of no more than 4 km / h.

The drive of a rotary snow blower is easier to make a belt. If the auger is jammed, the belts will simply slip on the pulleys. Can be installed on a snow blower and chain drive through sprockets. However, if a large solid object enters the auger, there is a risk of breaking the chain or breaking the teeth on the sprockets.

Chainsaw powered snow blower

If there is no walk-behind tractor at home, then the simplest snowplow can be assembled with a chainsaw engine. Such a primitive option is suitable for giving, where snow will not have to be removed very often.

The same rotary snow blower remains the working mechanism. The implementation of this project is aimed at the manufacture of a traction device – a machine. The motor is taken from an old powerful chainsaw, for example, “Friendship”. To fix it, you need to weld the frame. There is no need to invent anything complicated here. The snowplow will not be self-propelled, so the frame is welded from four pieces of the channel, and the axle of the wheelset is fixed from below. The motor itself is bolted on top.

If you want to have a self-propelled snowplow, then you will have to adapt a gearbox to the frame, which will transmit torque from the engine to the wheelset. In this case, you can leave your native asterisk on the chainsaw motor. A similar part is fixed on the axle of the wheelset. Now it remains to put on the chain, and you get a direct drive for the snowplow.

In the final, it remains to weld the handles to the frame from behind. A hitch with a rotary nozzle is organized in front. All working bodies of the snow blower are covered with a removable casing made of tin.

Electric snow blower

To assemble a homemade snow blower with your own hands with an electric motor, you must start work again with the manufacture of the frame. Handles are attached to it. Instead of a pair of wheels, a snowplow can be put on skis, but in some difficult areas such equipment will be harder to push.

The nozzle again acts as a rotary snow blower. To transmit torque to the auger, a set of pulleys is used. A belt drive is assembled from them, which is hidden under a steel protective casing. You can organize a snow blower chain drive through sprockets. However, when the mechanism is jammed, there is a threat of burning the electric motor.

Sometimes craftsmen additionally reinforce the rotary nozzle with a fan. An example of such a snow blower is shown in the photo. The fan blades are inside a round volute with a snow ejection pipe, which is tightly connected to the body of the rotary nozzle. During rotation, the auger scoops up snow and feeds it with blades to the outlet nozzle. The fan impeller behind it draws in the supplied mass, after which it is thrown out through the outlet sleeve with a strong air flow.

It is better to take a three-phase electric motor for a screw machine, with a power of at least 1,5 kW. The disadvantage of such a snow blower is the constantly dragging cable and attachment to the electrical panel where the connection is made.

The video talks about making a snow blower from an electric trimmer:

Conclusion

You can assemble a snowplow from almost any home appliance that has an engine. It is only important to remember that snow is water. Electric homemade products carry a certain danger of electric shock. It is best to give preference to gasoline engines.