Many craftsmen are accustomed to making equipment for themselves. This also applies to mini tractors. The unit is made with a solid or broken frame. The first option is easier to manufacture, and the classic – breaking is considered more maneuverable. You can fold the unit from old spare parts or buy a kit for reworking the walk-behind tractor. Now we will look at how a home-made mini-tractor of a break 4×4 is assembled and figure out what is needed for this.

What is a fracture

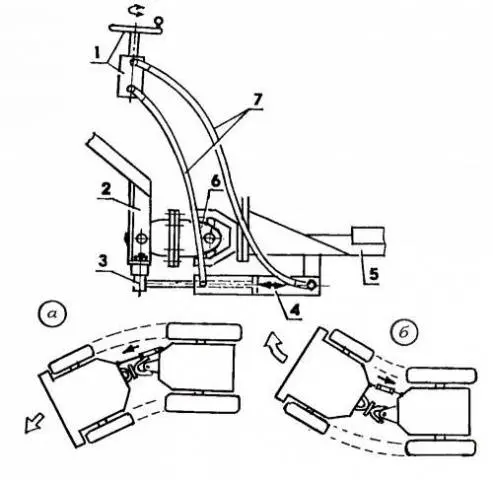

Externally, the breakage mini-tractor is no different from the usual compact tractor model. When self-made, such a technique is most often assembled on the basis of a walk-behind tractor. The main design difference is the broken frame, which consists of two parts. This is where the name came from.

When self-assembling fractures, you need to have a mini-tractor diagram on hand, where the dimensions of all units are indicated. When everything is calculated to the smallest details, you can start assembling.

What and how to collect

There are many options for assembling homemade products, since each craftsman makes his own adjustments to the drawings. In general terms, the process of creating a 4×4 fracture looks like this:

- The assembly of the mini-tractor breaks begins with the manufacture of the frame. Despite the rough shape of the two semi-frames, all chassis assemblies are positioned efficiently. A special feature of the frame is the three-stage design of the side members. Elements of the front steps are made of tens of channels. The last step can be made from a profile pipe with a cross section of 8×8 cm. Channel # 12 is suitable for the front traverse, and channel # 16 for the rear one. Crossbars are made in a similar system.

- You can take any motor for a fracture mini-tractor that is more suitable in size, fastening and power. A 40-horsepower four-cylinder diesel is a good fit. With. Water cooling will keep the motor from overheating, even if the tractor is on the field all day without interruption.

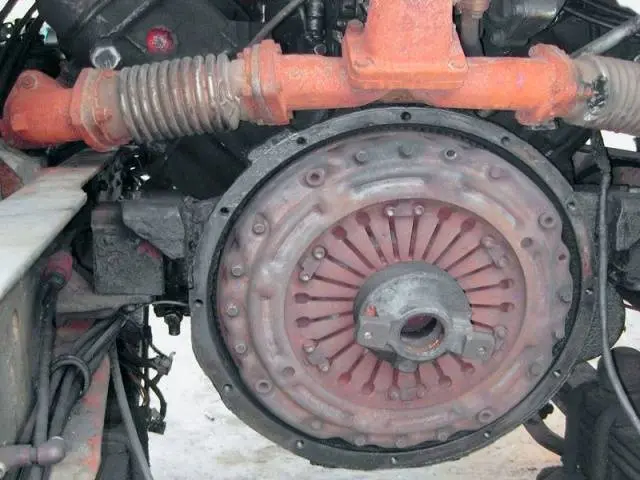

- After installing the engine, a power take-off shaft, a transfer case and a gearbox are installed on a mini-tractor with a fracture frame. They can be removed from a decommissioned GAZ-53 truck. To dock the clutch to the engine, you will have to redo the flywheel. To do this, cut off the rear part on a lathe, and then grind a new span in the center. Retrofitting the clutch basket cover is based on a fit.

- The rear axle will fit any vehicle. He does not need to make any changes. The same goes for the propeller shaft.

Next, you need to install a good wheelbase and steering on a mini-tractor with your own hands.

The video shows the gimbal for breaking 4×4:

Wheelbase installation

The choice of wheelbase size must be approached wisely. Often a mini-tractor is equipped with wheels from a passenger car. You can do that too. The main thing is that the dimensions of the front axle discs are at least 14 inches. Otherwise the tractor will load in the ground. However, you can not overdo it with the size. Large wheel diameters will make handling difficult. You can correct the situation by installing a hydraulic control system, which is completely removed from the old agricultural equipment.

You can assemble the front axle yourself from a piece of pipe with mounted bearings. Alternatively, it can also be removed from other equipment and put on a tractor without modification.

To achieve good shock absorption, it is advisable to install 18-inch tires on the rear axle. It is not difficult to fix the wheels to the hubs of the rear axle of a truck. First, a grinder or cutter cuts out the central part of the disk, where the mounting holes are located. The same part is welded into this place, only cut out from the disk of the ZIL-130 car.

Steering installation

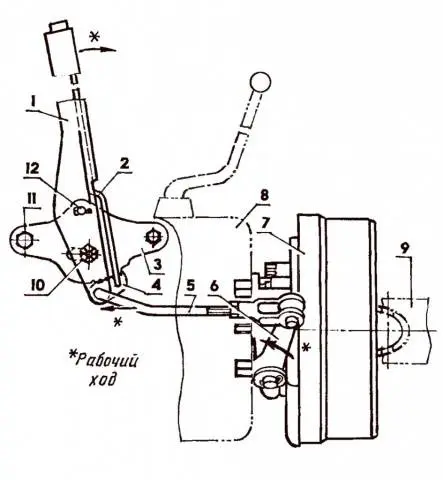

For breaking the steering is suitable from any passenger car. But in order to increase the maneuverability of the equipment, it is desirable to install hydraulics. It will make driving the tractor easier. The entire system is removed from the old agricultural equipment. You will also need an oil pump, which is driven by the motor. It is optimal to make sure that the wheels of the main shaft are controlled through a gearbox. In the photo, we offer to see the drawings of the main control units.

When installing the steering, it is important not to forget to put a hydromechanical drum brake. It is connected to the pedal with the help of traction.

When all the main components are ready, proceed to the design of the unit. That is, they equip the driver’s workplace by installing an adjustable seat. The canopy of the summer cab can be attached to the four poles welded on. The engine and all other components are hidden under a steel casing for safety. It can be bent from galvanization. For night work, the tractor is equipped with headlights. Only it will be necessary to adapt the place on the frame for the battery.

Here, according to this principle, a do-it-yourself mini-tractor is assembled from old spare parts. In words, everything is done simply, but in reality you will have to invest a lot of work and patience.