Contents

The agricultural industry supplies the market with raw materials for food production. Corn is a high-yielding crop, the grains of which are used for food and technical purposes. Growing a plant is easy. Harvesting of corn for grain, features of cultivation, drying, cleaning and storage are described below.

The place of corn in the crop rotation

The yield of a crop can fall, rise, depending on the state of the earth, its fortification, humidity, and predecessors. Corn is a drought-resistant plant, but to obtain an average yield of 8 t / ha, 450 – 600 mm of precipitation is needed during harvesting.

Corn produces little grain after crops that dry up the soil:

- sunflower;

- sorghum;

- sugar beet.

In dry areas, the recommended grain corn precursors are:

- winter wheat;

- legumes;

- potatoes;

- buckwheat;

- spring cereals;

- mustard;

- rape;

- coriander.

Thanks to modern technologies, corn can be grown as a monoculture 2-3 years in a row in one place, and in fertile soils with high rainfall – 4-5 seasons.

Preparing corn kernels for planting

The processing of seed material is carried out by special enterprises – corn processing plants, where grains after passing through special technological processes can be immediately planted in the ground. If it is not possible to deliver corn to the enterprise, then you will need to prepare it yourself.

Grain required:

- calibrate;

- pickle.

Calibration – separation of seeds by size, is carried out to separate large samples that can get stuck in the hole of the seeding combine from small corn. Further, the grains are subjected to solar or air-thermal heating for a week to accelerate germination.

Dressing is carried out to increase the protective properties of seeds between sowing and germination. Grains that have absorbed water have an alkaline environment, so they become a breeding ground for fungi that are in the ground. The fungicide creates a protective film that prevents the development of diseases before germination.

For seed processing use:

- Insecticide.

- Fungicides.

- A mixture of the first and second types.

Drugs and their recommended dosage:

- Tiram — with active substance Tiram 4 l/t;

- TMTD – with the active ingredient Tiram 2 l / t;

- Aatiram – with the active substance Tiram XNUMX kg / t;

- TMTD98% Satek – with the active substance Tiram 2 kg / t;

- Vitavax – with the active substance Carboxim + thiram Z l / t;

- Vitatiuram – with the active ingredient Carboxim + thiram 2-3 l / t;

- Maxim Gold AP – with the active substance Fludioxonil + mefenoxam 1 l / t.

Sowing corn for grain

The term for planting seeds is determined by weather conditions, weediness of the field, precocity of the variety and soil temperature, which at a depth of 10 cm should warm up to 10 – 12 ° C. Cold-resistant crops are planted at a temperature of 8 – 10 ° C. Sowing of corn for grain is carried out in a dotted way with the help of tractors.

Density and seeding rate of corn for grain

Sowing material is brought into the ground in early spring, most often from May 1 to May 15. The sowing density per hectare depends on the fertility of the land, rainfall, germination and other parameters. The average rate for the standard technology of growing corn for grain:

- in arid regions: 20 – 25 thousand;

- in the steppe and forest-steppe zone: 30-40 thousand;

- with regular watering: 40 – 60 thousand;

- in the southern regions on irrigated soil: 50 – 55 thousand.

Quantitative expression of sowing density – 15 – 22 pcs. for every 3 linear meters, and in terms of weight – 20 – 30 kg per hectare. If field germination is poor, the rate is increased by 10-15%. Planting depth is 5 – 7 cm, in dry soil – 12 – 13 cm. Row spacing should be at least 70 cm.

Density of standing maize before harvest, expressed in thousands of plants per hectare.

Ripeness group | Steppe | Forest steppe | Polessye |

FAO 100-200 | 65 – 70 | 80 – 85 | 90 – 95 |

FAO 200-300 | 60 – 65 | 75 – 80 | 85 – 90 |

FAO 300-400 | 55 – 60 | 70 – 75 | 80 – 85 |

FAO 400-500 | 50 – 55 | — | — |

Grain Corn Fertilizer

Corn draws out 24 – 30 kg of nitrogen, 10 – 12 kg of phosphorus, 25 – 30 kg of potassium when forming 1 ton of grain, so it is necessary to replenish the elements or add them when there is a shortage. Feeding rate: N – 60 kg, P- 60 – 90 kg, K – 40 – 60 kg. Fertilizers for grain corn are applied carefully, because a lack of nitrogen reduces the yield, and its excess delays ripening.

Before autumn plowing, rotted manure, phosphorus-potassium fertilizers and half of the nitrogen-containing substance are added. They are evenly distributed over the field by rotary spreaders, and with small field volumes – manually.

Pre-sowing top dressing of corn for grain has a good effect on growth and yield. With seeds, superphosphate is introduced into the ground. It should be 3 – 5 cm deeper than the seed and 2 – 3 cm further so as not to damage the sprouts.

During the primary and secondary processing of row spacings, the second half of nitrogen fertilizers is applied. To increase the protein content, foliar spraying with 30% urea is necessary before harvesting.

Stages of ripeness of corn

The grains ripen gradually, becoming harder at each stage. There are 5 stages of ripeness:

- dairy;

- early wax;

- late wax;

- vitreous;

- complete.

Grain corn harvesting dates

The crop is ready for mowing when 65 – 70% of ears have reached wax maturity. There are two ways to harvest corn:

- On the cob with a percentage of moisture in the seeds is not more than 40%.

- In grain with their moisture content of 32%.

Corn harvesters are engaged in corn harvesters, or corn harvesters, as they are also called. For threshing, stream headers are used – special attachments to grain harvesting equipment, which clean the cobs from seeds during harvesting.

Grain corn harvesting technology

All types of combine harvesters with tangential or axial threshers are used. The quality of harvesting corn is affected by two indicators:

- the scheme of the movement of equipment;

- level of quality.

The serviceability of the combine is checked before entering the field. Unloading equipment is also subjected to a thorough inspection.

The scheme of movement of combines for collecting grain

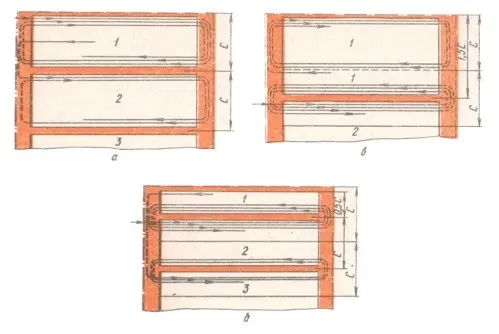

Cleaning is recommended to be carried out in the same direction in which it was planted. The field before the work of the combine is mowed along the perimeter, divided into paddocks, starting from the butt aisle. There are 2 ways to harvest corn for grain:

- racing;

- circular.

The last movement pattern is used in small fields.

Scheme of the rutting method of cleaning:

1, 2, 3 – paddocks, C – width.

The productivity of a combine harvester with a six-row corn attachment is 1,2 – 1,5 ha/h. The indicator depends on the time spent on shipment – when pouring onto a trolley, the value is higher than when leaving for the edge of the field.

How corn is harvested for grain can be seen in the video:

Combine quality indicator

Corn harvesting equipment does not always work well. The quality of crop harvesting can be assessed by indicators:

- grain loss;

- cutting height;

- cleaning;

- the number of damaged cobs.

To determine the quality of work, it is necessary to collect seeds and ears on an area of 10 square meters. m – 3 times. Knowing the crop yield, and weighing the collected residues, determine the amount of loss as a percentage.

Handling corn after harvest

Wet grains with garbage are not stored for a long time, therefore, before being sent to the hangar, they are cleaned of extraneous plant residues and then dried. Feed grains are stored for a short time, so more moisture is allowed in them than in seeds intended for planting.

cleaning

To remove unwanted impurities, corn is passed through cleaning units. They come in 5 types according to the way they work:

- air;

- air-sieve;

- separators;

- trier installations;

- pneumogravity tables.

In the aggregates, the seeds go through 3 degrees of purification:

- Primary: to eliminate weeds, leaf debris and other debris.

- Primary: to separate excess impurities.

- Secondary: for sorting by fractions.

Drying

Grain after harvesting is wet, contains a lot of mineral, organic impurities, so it is poorly stored. Further processing of corn consists in dividing the seeds into categories according to moisture content. With a humidity of 14 – 15% they are sent to storage immediately, at 15,5 – 17% – for drying and ventilation, with a high percentage of water – in a drying chamber.

Drying units are of several types:

- mine;

- columnar;

- bunker.

Drying plants by technological mode of operation:

- Direct-flow. They reduce grain moisture by 5-8%, but require material homogeneity.

- Recirculation. They do not require the same moisture content of corn, they dry better.

To make moisture evaporate faster, use different drying modes:

- with preheating;

- with alternating heating-cooling;

- with mild temperatures.

Dry corn storage

After harvesting, cleaning and drying, the seeds are sent to storage. Corn for mixed fodder is stored with a grain moisture content of 15-16%, for the production of products – 14-15%. So that the seed does not deteriorate during the year, it is necessary to dry it up to 13 – 14%, more than a year – up to 12 – 13%.

Storage of corn for grain for technical, food, fodder purposes is carried out in granaries and bunkers in bulk. The height of the pile is only limited by the roof of the storage, the convenience of quality control and maintenance. During storage, regular cleaning of the room is required.

Conclusion

Harvesting of corn for grain is carried out when wax maturity is reached. Corn harvesters harvest the cobs or thresh them immediately. Harvesting is carried out at the stage of wax maturity of the culture. Store grain in a dry, well-ventilated room after cleaning and drying.