Contents

Probably, every vegetable grower is thinking about building a simple, inexpensive greenhouse, which you can assemble with your own hands from construction residues or improvised means. A greenhouse made of fiberglass reinforcement is just such an option – budgetary and interesting in execution. The design of reinforcement is quite reliable and durable, and if you study the technology of its assembly, then in just a couple of hours you can build a strong and functional greenhouse on the site.

Greenhouse construction

As it has already become clear, the greenhouse is assembled from fiberglass reinforcement. This is a spiral ribbed profile consisting of glass, polymer and other composite fibers. It is from such material that the main load-bearing structural element, the frame, is erected with their own hands. As a rule, the frame of the greenhouse has an arcuate shape, since it is easiest to bend the reinforcement into this position.

It should be said that reinforcement is an ideal material for building greenhouses with your own hands. It bends well, is easy to process, harmoniously fits into any design and, importantly, its cost is literally a penny. You can create a project for such a greenhouse yourself, without having any special knowledge in the field of construction and architecture.

The simplest greenhouse design is made up of the following parts:

- base support (the so-called foundation) – the easiest way is to make a wooden support, however, if you wish, you can also lay a real concrete foundation, but you need to take into account that such a greenhouse will no longer be portable or you will have to spend a lot of effort to move it, and possibly even funds;

- outer frame – this part of the structure is assembled by hand from fiberglass reinforcement curved into an arc, which is attached to the base (support), and connected to each other using longitudinal rods;

- doors – to fasten the doors, you need to mount an additional section of reinforcement with hinges (the doors themselves, as a rule, are made of the same material that is used to cover the structure, but you can also use ready-made ones);

- sheathing – polycarbonate can be taken as a coating for a greenhouse, but this option can hardly be called economical, so most often a greenhouse is covered with a film.

As for the base support, it is a rectangle of arbitrary size, consisting of long boards or several bars fastened together. Its function is to hold the frame and the greenhouse itself on the surface.

Advantages

When choosing a fiberglass greenhouse project, you want to make sure that such a greenhouse is really better than other structures consisting of traditional materials. The advantages of fiberglass reinforcement are obvious:

- it is very light, so it does not cause difficulties in moving and transporting;

- resistant to corrosion;

- bends well and at the same time does not lose its strength, due to which structures made of it are considered quite rigid and reliable;

- easily takes its original shape – after disassembling the greenhouse, the rods do not take up much space;

- it is easy to build a greenhouse from reinforcement with your own hands – the simplest design is assembled in 1–1,5 hours;

- the reinforcement structure can be adjusted to any size, as well as supplemented with various openings, sections;

- the cost of reinforcement is quite low – not a single building material is as cheap as fiberglass reinforcement;

- the design is made up of modules, which makes it easy to carry and modify.

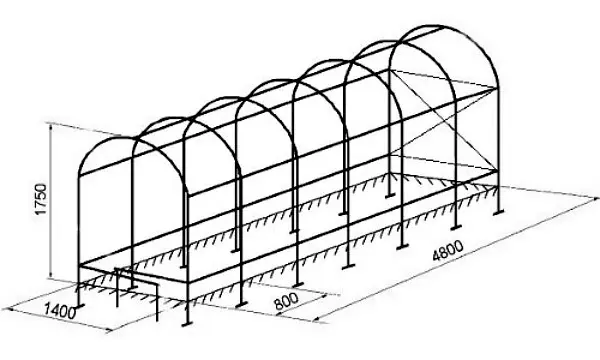

Drawing of a greenhouse frame made of fiberglass reinforcement

In fact, these arguments are more than enough to consider fiberglass reinforcement as an ideal material for building a greenhouse with your own hands. For a low cost, you get a high-quality, durable and functional greenhouse.

Necessary materials and tools

The construction of any greenhouse begins with the selection and purchase of materials. In this case, we will consider the design of a simple structure, consisting of a wooden base, a frame made of reinforcement and upholstery made of foil. To build such a structure, you will need the following materials:

- wood (bars or boards) – if we consider a portable option, then bars are best suited for it, but high-quality wooden slats can also be used;

- reinforcement (its diameter and quantity depends on the size of the future greenhouse) – for a structure with a size of 6 x 3 m and a height of 1,8 m, 50 m of reinforcement (10 arcs of 5 m each) with a section of 10 mm are required;

- film – if you buy a new one, then its total area should be 50 square meters. m, but you can also use the used film, which remained from the repair work, and this may not be a single piece, but several different pieces.

Additionally you need to purchase:

- bolts, screws, nuts, nails – the length of the fastening material must necessarily exceed the thickness of a wooden block or board;

- ridge fittings with a large cross section (used to fix and strengthen the support);

- wooden or metal corners (for fastening the base).

You will also need the following tools: drill, tape measure, square, screwdriver, hammer, saw, construction stapler. A jigsaw and a grinder can also come in handy, but usually building a temporary greenhouse with your own hands is somewhat easier.

This set of tools and materials is needed for the construction of a portable and temporary structure.

If a stationary winter greenhouse is built from reinforcement, then double-glazed windows and sheet fiberglass cannot be dispensed with. This material is able to withstand low temperatures, and in addition, it is possible to conduct electricity in a double-glazed greenhouse and make heating.

Assembly technology

The process of building a greenhouse with your own hands is quite simple. If we consider the assembly technology in stages, then it is as follows:

- prepare the necessary materials and equipment;

- then you need to prepare a site for assembling a greenhouse – level the surface of the earth, remove stones, roots and other debris;

- we bring a tree to the site, unfold the film;

- then we fasten the boards so that we get a rectangular base;

- install and strengthen the support on the surface of the earth;

- now we cut the reinforcement into pieces of the same length (roofing scissors can be used to cut the profile);

- pieces of reinforcement are alternately buried in the ground inside the support to a depth of about 30 cm, then we attach them to wooden beams using a stapler or other available method;

- we strengthen the support with ridge reinforcement (the rods are attached longitudinally in the form of a grid);

- then you need to install sections with doors and windows (if the latter are available);

- now we once again check the reliability of the structure, additionally strengthen weak points;

- in conclusion, we stretch the coating (film), fix it with a stapler from below to the support and at the points of contact with the reinforcement.

So the prefabricated temporary greenhouse is ready. The stationary winter structure is mounted according to the same principle, only double-glazed windows are used as a coating.

Video “Assembling a greenhouse from fiberglass reinforcement”

See how easy it is to assemble a homemade greenhouse from fiberglass reinforcement and plastic film.

Author: Svetlana Galitsina

Loading…