Contents

- How did the gin basket come about?

- Types of gin baskets

- Features of the operation of genie baskets

- How to connect the basket to the column correctly: with steam supply from above or from below?

- How often do you drain the sediment from the gin basket?

- Is it possible to connect a genie basket without using a drawstring with a nozzle and a dephlegmator?

- Is it possible to connect a genie-basket to a column with steam sampling up to a dephlegmator-condenser?

- Can a Soxhlet extractor be used instead of a gin basket?

This article discusses the basic principles for the preparation of aromatic spirits and drinks without distillation of raw materials – tinctures, alcoholized juices and fruit drinks, as well as the features of the operation of a gin basket in moonshine stills and columns.

Theory. First, let’s define terminology. Tinctures are made on roots, dried fruits, bark, etc. If the extract is obtained by squeezing the juice with its further fortification with alcohol, alcoholized juice will eventually come out. If the organoleptic properties (taste and aroma) of raw materials are extracted by several infusions of juicy raw materials in solutions with decreasing strength, the drink can be classified as fruit drink.

Tinctures, alcoholized juices and fruit drinks are saturated with both volatile and non-volatile soluble components of raw materials. This is their fundamental difference from aromatic alcohol, which contains only volatile substances, regardless of solubility.

A variety of properties of extractable substances allows you to create rational technologies and equipment for the manufacture of beverages, separating the necessary and leaving unnecessary substances. All methods for preparing aromatic drinks are reduced to three options recommended in 1971 in the technological instructions for the distillery production of the USSR.

Option “a” does not provide for preliminary infusion of raw materials and is used for the production of gin. The method has a popular modification, when raw materials are loaded not into a cube, but into a gin basket. This avoids the boiled (compote) taste of the drink, since the process is steamed. In fact, this is the extraction of volatile impurities from raw materials, regardless of their solubility.

Option “b” has come down to our time with some changes. It is believed that if the raw material is subject to distillation, then there is no point in long-term infusion. Maceration is enough – soaking in sorting (a mixture of water and alcohol in the required proportion) for 12-24 hours.

The main advantage is the separate extraction of soluble substances into the infusion of the first drain and volatile substances into the distillate. This is followed by blending, during which the infusion is not just mixed with distillate, but in the right proportions. The process is under the control of the master distiller, with periodic tasting and the addition of additional components – alcohol, water, sugar, etc.

Option “c” has not changed much. Long-term infusion allows the most complete extraction of soluble volatile and low-volatile substances, which, during subsequent distillation, enter the product. This is not always good. For example, in the production of gin, it is soluble low-volatile substances that give a soapy aftertaste.

To obtain aromatic spirits, there are various devices, the most popular of which in home distillation is the gin basket.

How did the gin basket come about?

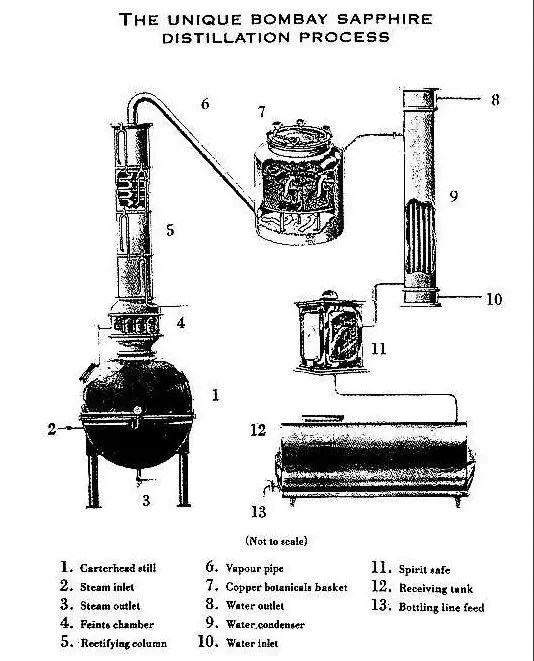

The gin basket was invented by the Carter brothers. In its original form, it looked more like a dry steamer, through which steam was directed on its way from the distillation column to the refrigerator.

The device was simply called a basket for loading aromatic raw materials in the production of gin. It seemed easier to the lazy and currently unknown translator to combine everything into one word. This is how the term “gin basket” was born.

Types of gin baskets

The designs of modern gin baskets do not shine with variety and come down to several options.

The simplest design is a basket placed directly in the neck of the cube on its way to the column.

The disadvantage of this method of placing flavors is that they are washed with foam in the cube during the distillation process. This can give the drink a specific boiled flavor. Such a gin basket is similar to the use of dry steamers, where the raw material boils in a “puddle”.

In addition, it is necessary to reasonably dose the amount of raw materials to be poured. During processing, it becomes saturated with liquid and swells, which can lead to clogging of the steam pipe.

A more advanced method: a gin basket without a drain cock, which is installed in a column gap above a reflux condenser or on a downward steam flow in front of a refrigerator. The debate about which is better is pointless. Both options are bad.

In the first case, the sediment flows through the reflux condenser into the column and contaminates the packing. Because of this, even after disassembling half a column and replacing the flavoring, it is impossible to get another drink. You also need to rinse the nozzle.

To avoid these unpleasant operations, it is enough to install an intermediate (full) selection partition between the gin basket and the reflux condenser and divert all the flowing phlegm through a long PVC tube into a separate dish. Steam will not break through, it is enough to make a tube one and a half meters long. Such knots are used as a set with pasteurization drawers or as knots for the lower selection of phlegm enriched with fusel oil. The main thing is that the design ensures complete selection.

Numerous nodes for the selection of “heads”, in which the lion’s share of phlegm flies through the node, and the selection comes only from the walls, are not suitable. It is necessary to remove all the condensate formed in the basket from the column.

In the second case, when the basket is installed above the refrigerator, the sediment is sent to the selection, which is often also bad. For example, in the production of gin, this phlegm is saturated with soluble but non-volatile substances that give the drink a soapy taste and turbidity. Although there are a number of flavors for which this is not essential.

There are modifications of gin baskets installed at the very top of the column and having a side outlet for steam outlet to the refrigerator. Some models with the help of corner bends shift the body of the basket from the axis of the column. Both options solve only the issue of quick replacement of raw materials.

The problem is solved, as in the previous case, by installing a selection node.

The second option allows you to work for some time without draining the sediment into the cube, at least until the glass is filled. These designs became the prototypes for most modern baskets equipped with a drain cock or a complete selection unit built into the basket.

In expensive models, a diopter is added to monitor the process and timely drain the sediment. As a rule, these gin baskets are equipped with 1,5 or 2 inch clamp connections, and are intended for use in beer columns with steam extraction after the reflux condenser.

The most popular and rational gin baskets with a body diameter of 3 inches. They have rather large loading hoppers, which make it possible to conveniently and rationally obtain drinks with different flavors, changing the load during one distillation.

Baskets with a diameter of 4 inches at home are too large.

Features of the operation of genie baskets

As a rule, when using genie baskets, a number of standard questions arise.

How to connect the basket to the column correctly: with steam supply from above or from below?

There is no difference, connect, based on overall considerations.

How often do you drain the sediment from the gin basket?

The main thing is that the flavoring hopper does not sink and does not begin to boil in the sediment.

Is it possible to connect a genie basket without using a drawstring with a nozzle and a dephlegmator?

It is possible, but then it is not raw alcohol that needs to be poured into the cube, but the finished sorting or distillate. This is most often done, since it is easier to store the finished product than the semi-finished product.

Is it possible to connect a genie-basket to a column with steam sampling up to a dephlegmator-condenser?

Yes, install in the gap between the valve that regulates the amount of steam that goes into the extraction and the refrigerator. That is, on the downward flow of steam. But at the same time, the additional resistance exerted by the gin basket to the flow of steam can completely stop the selection. To avoid this, it is necessary to place a narrowing ring above the distribution chamber at the inlet to the condenser. Its inner diameter is selected experimentally.

If the column has an internal diameter of 48 mm, then the outlet to the cooler is usually made with a diameter of 24 mm. This provides a maximum reflux ratio of 4 with the valve fully open. But this is pure geometry, in fact, the pressure in the distribution chamber drops. Steam going in a column with a diameter of 48 mm enters a chamber with two outlets, the total cross section of which is 1,25 times larger, and it has a choice where to go – to a dephlegmator or to a refrigerator. In this case, the rise vertically upwards for steam is a priority in comparison with the movement to the side outlet. Arithmetic gives in to physics.

For confident adjustment of the extraction rate, it is necessary to narrow the diameter of the flow section into the reflux condenser by installing a ring with an inner diameter of at least 42 mm. This will give equality of the cross-sectional area at the inlet and outlet of the distribution chamber. If the diameter is further reduced, then the pressure in the chamber will become excessive, and the controllability will improve even more. Naturally, you need to know the measure. In most cases, a slight overpressure is enough – the result will be noticeable.

If you install a genie basket on the path of steam going along the side outlet to the refrigerator, then you need to estimate how much the flow area to the refrigerator will be narrowed. If there is no narrowing, most likely, everything will work immediately and without additional hassle. Otherwise, you need to pick up a ring to create a slight overpressure and balance the volume of steam sent to the extraction and return.

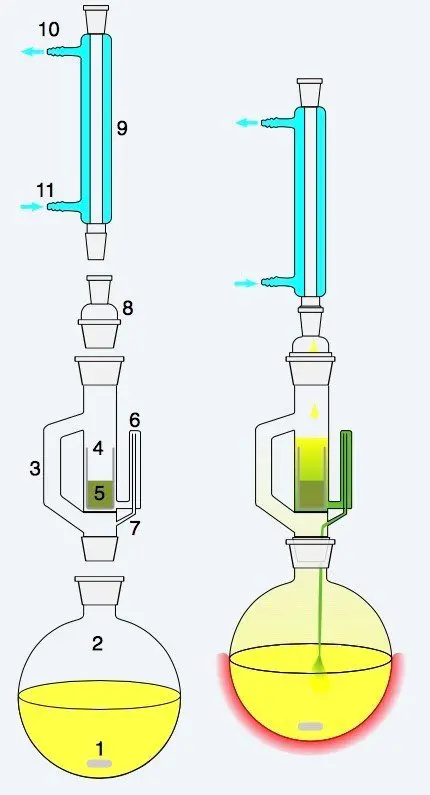

Can a Soxhlet extractor be used instead of a gin basket?

No. They are different tools and have different purposes. A gin basket is needed to extract volatile substances from raw materials. The product saturated with them is obtained after the condensation of steam in the selection. The contents of the basket are not boiled, but evaporated. Ethers and other volatile substances are included in the selection.

The Soxhlet extractor is designed for washing out hardly soluble non-volatile substances by repeatedly washing them with hot distillate. If you look closely at its device, the first thing that catches your eye is that steam does not meet fragrant raw materials at all, but rises up through the side bypass tube (3) into a dephlegmator (9) and flows down hot phlegm onto raw materials (5). In this case, the steam washes everything that is possible. As soon as the amount of this decoction in the glass (4) reaches the top of the siphon (6), everything flows into the cube. This is the final product for the Soxhlet extractor. If the liquid is then distilled, then the resulting distillate will bear a clear trace of the process – the taste of boiled herbs or fruits.

For the purposes of distillation, the use of a Soxhlet extractor is impractical.

PS Concluding a brief story about the features of using gin baskets to obtain aromatic alcohol, it is necessary to recall the safety rules. The use of a genie basket does not reduce the dangers of our hobby, but on the contrary, it creates additional risks. Be careful!

The author of the article is IgorGor.