Contents

Even the most expensive hoods do not cope with their purpose by 100%. As a result, the surrounding space is still saturated with the smells of food. This problem can be solved by a gazebo attached to the house with a barbecue or barbecue.

Types of extensions

Open-type gazebos contribute to a relaxing holiday in the bosom of nature. Here it is especially pleasant to arrange tea parties, celebrate family holidays and learn the basics of science. Fully glazed outbuildings provide better protection from the cold. They let in up to 95% of natural light, due to which it is possible to visually expand the space.

Structures with non-standard forms are preferred by supporters of the loft and hi-tech. They contribute to a clearer delineation of functional areas. Based on the shape and purpose of the seasonal building, you can choose the optimal type of roof:

- a flat roof with a minimum angle of inclination facilitates finishing work at height;

- single-sided version minimizes the cost of installing roofing materials;

- a gable roof is more suitable for square and rectangular buildings;

- a multi-level roof is the best solution for octagonal gazebos equipped with barbecues or electric cooking appliances.

Video “Terrace-gazebo attached to the house with their own hands”

From this video you will learn how to attach a gazebo terrace to the house with your own hands.

How to build yourself

To begin with, it is important to determine the raw material base. For example, buildings made of wood retain heat better than any metal structures. But in the absence of regular surface treatment with protective compounds, they quickly become unusable. Brick gazebos attached to the house retain an attractive appearance in any climate. In addition, they provide high-quality thermal insulation of the premises.

Plastic extensions demonstrate good resistance to aggressive environments. However, due to their flammability, barbecues and stoves cannot be used in them.

For self-construction, you will definitely need shovels, hammers, drills, a building level, tape measure and power tools. If you make a shallow foundation – a concrete mixer, cement grade M-400, crushed stone and sand.

When choosing a site for future construction, it is important to take into account the visibility of the most attractive objects and the level of its illumination. It must be flat and dry. The bumpy place will have to be leveled with special equipment, and the roots of the trees uprooted. If the groundwater is fairly close, you will have to find another area.

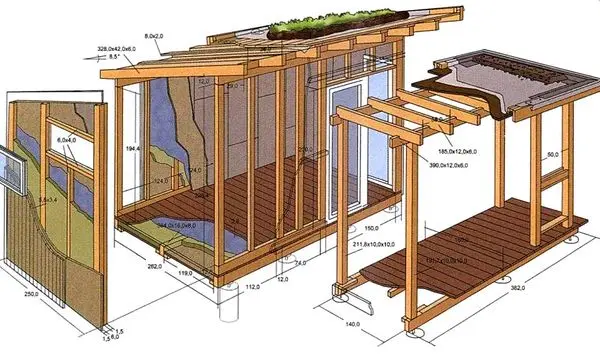

A detailed drawing of the gazebo will allow:

- accurately calculate the required amount of finishing materials;

- choose the best place for a brick oven and barbecue;

- avoid unnecessary costs in the construction of walls and the installation of a truss system;

- attach a gazebo to the main building in the shortest possible time.

The image should detail the location and dimensions of each structural element. This refers to supports, gratings, crossbars, shingles, lower and upper strapping. Separately, you need to make a sectional drawing of the furnace.

Base

Lightweight plastic and metal structures can be installed on a concrete surface. In the case of capital structures made of stone, a monolithic foundation is required. First you need to mark the base line on the site, dig a trench, tamp a sand cushion at the bottom of the pit, install formwork and make a reinforced frame. At the end of the work, pour concrete and compact the mortar with a vibrating plate. In this case, the air will definitely come out of the mixture, and the base will turn out to be reliable.

In order to avoid cracks in the first days of concrete drying, it should be sprayed with cold water. Final hardening is possible only after 10-12 days.

Wall supports

For work, profiled bars with a thickness of 100-125 mm are needed. Unlike conventional lumber, they contain grooves on both sides. The rectangular section increases the contact area of the rims, and the optimal density of the bars contributes to the creation of an inextricable array. Thus, the rigidity of the walls, their resistance to moisture and penetrating winds increases.

The side pole is needed for mounting the rafters. If everything is done correctly, the supports will hold the surfaces for many years. The corner posts adjacent to the wall must be at least 50 cm higher than the others, otherwise the roof will not slope. In this case, there is no need to talk about high-quality drainage.

Rafter system

To install the most practical and inexpensive do-it-yourself shed roof, you need to perform a number of operations:

- Attach the upper Mauerlat to the wall of the building, that is, firmly fix the lower support. To do this, you will need several bars with a section of 50×200 mm and up to ten anchor bolts.

- Install the rafters using hot-rolled corners (70×70 mm). Due to the increased rigidity, they withstand maximum load, and their light weight contributes to quick installation.

- Lay a wooden crate and about 9 profiled sheets on top of the supporting structure. Self-tapping screws with washers are useful in the work.

When using euroslate on the roof, you will have to install refractory cuts. With their help, you can quickly put out the fire.

Sheathing

To finish the exterior, you will need frost-resistant ceramic bricks. It almost does not absorb liquid and tolerates temperature changes well. Flammable vinyl siding is best replaced with cement siding. This is ideal for arranging the furnace zone. From other materials, slatted planks or a block house, which looks like rounded logs, are suitable.

For the roof device, you will need the same materials that were used when installing the roof of the main building. It can be soft tiles, asbestos-cement sheets, slate or corrugated board. The latter is most often overlapped at the rate of 6–7 sheets per 1 m².

Floor laying

Wood flooring can be laid on a concrete base. In this case, the wood should not come into contact with the stone surface. To do this, you need an intermediate layer of ground mastic, with which you can really improve the viability of the wood.

The optimal distance between walls and boards when laying the floor is 12–15 mm. To fix them, you will need screws and wedges. It is advisable to grind the joints, after which you can proceed with the installation of the finish coating.

When laying ceramic tiles, you must adhere to the optimal thickness of the adhesive.

How to install a brazier

In round gazebos in the country, barbecues with chimneys are installed right in the center of the buildings. At the same time, the distance between the kitchen area and the seating area should not be less than 2 m. Portable structures are more suitable for sheds and tents. Stationary with supports for fuel are intended for capital constructions from a stone and a brick.

In a large gazebo with an area of 12 m², it is possible to install a barbecue oven with a hood. If the budget allows, it is better to choose stationary structures, equipped with sinks and countertops.

From lighting fixtures you will need LED lamps and sconces. To decorate the extension – flowerpots, clay figurines and plastic crafts.