Contents

Wax is of great importance in beekeeping, as it is the basis for the construction of honeycombs by bees. The quantity and quality of honey largely depends on the quality of foundation. Today, many beekeepers know how to make this product on their own. There are several types of foundation, which you can make yourself at home.

What is foundation in beekeeping

Voshchina – a wax sheet in which recesses of a hexagonal shape are pressed through. Recesses are necessary for the rapid construction of honeycombs by insects. The foundation is attached to a special frame, which is subsequently placed in the hive.

What is wax and why is it needed

The main purpose of wax sheets is to unload the bee colony. The insects do not need to build the base for the comb, as the beekeeper places the finished wax sheets into the hive.

Natural foundation is the basis for honeycombs, which bees use as pantries for honey and “nurseries” for breeding. If you do not install foundation in the hive, hard-working insects will build honeycombs on their own, however, this will negatively affect the amount of honey, since construction takes a lot of time and effort from the bees.

Artificial foundation plays a very important role, it is intended for:

- Expansion of the nest of a bee colony.

- Increasing the productivity of honey family.

- Normal formation of a bee swarm with the onset of spring.

Bees make honeycombs using honey and pollen as building materials. Man went further and applied his own technology to make honeycombs.

Foundation types

Today, beekeepers use foundation made by hand from natural and artificial materials. Ideally, the honeycomb base should consist of pure white wax only. It is environmentally friendly, melts easily and leaves no residue at all. Honeycombs made from natural wax have many advantages: it is easy and convenient to work with them, the wax is plastic and melts at low temperatures.

The main disadvantage of natural foundation is that wax is a very soft and plastic material that requires special storage conditions and careful handling. Natural wax sheets cannot be reused.

Artificial foundation is made from special plastic. It has some advantages over wax:

- Lasts much longer.

- Sheets can be used many times.

- Less labor, time and money.

- The plastic sheet is much stronger than wax and almost does not deform during operation.

- Artificial sheets, like wax ones, can be made independently.

- The plastic sheet is easier and more convenient to store, as it does not break, does not bend and is not afraid of high temperatures.

In addition to the pros, artificial foundation for bees has several disadvantages:

- Voshchina needs constant inspection and treatment from various kinds of parasites and diseases. This should be done 3-4 times per season.

- Before attaching the leaf to the frame and placing it in the hive, a thin layer of wax must be applied to the leaf, which takes time.

- If the sheet deteriorates, it cannot be repaired and must be replaced with a new one.

Today, there is no reliable data on how bees perceive plastic foundation. In general, the use of artificial materials in beekeeping is undesirable.

How wax is made

Few beekeepers can boast that they make wax for their hives on their own. The lion’s share of the needs of beekeeping is provided by enterprises for the processing of wax materials. During the wax manufacturing process, raw materials are melted and poured into special rotating drums. The mixed hot wax mass is fed to the rollers, from which finished plates with embossed hexagonal recesses come out. At home, foundation is made in several ways: using foundation rollers or a special press.

Foundation rollers

They are a rather simple, but effective device for making foundation with your own hands at home.

The simplest manual rollers consist of:

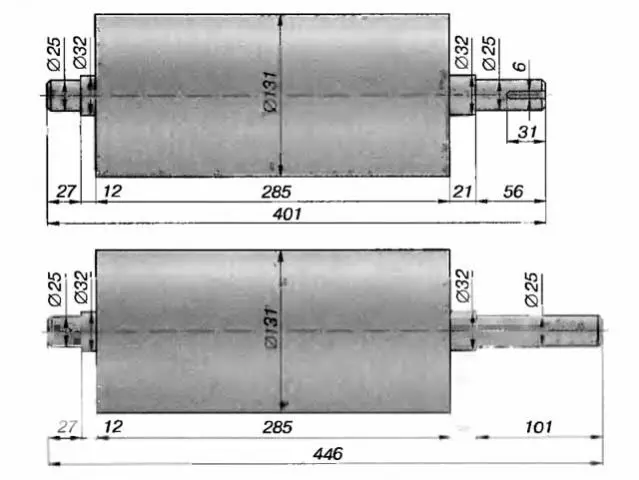

- Two engraved shafts through which wax is passed. They give the sheet the necessary relief, more often they are made of strong hardened steel. The corrugated surface is treated with special polymer compounds so that wax does not stick.

- Two gears with which the rollers are driven.

- Several adjusting bolts, the purpose of which is to set the desired distance between the rollers (adjusting the sheet thickness).

- The base on which this whole simple structure is attached.

In the process of honeycomb production, both finished sheets purchased from the manufacturer and material of our own production can be passed through manual rollers. It is not difficult to make a sheet of wax. The easiest way – a sheet of plywood or glass of the right size is immersed in a container with molten raw materials. After the wax has cooled, it easily separates from the base. As a rule, in order to obtain a sheet of the required thickness, the base has to be lowered into wax several times.

Another, more civilized way, which allows you to get the foundation of the desired thickness the first time, involves the use of special rollers with smooth shafts. A heated bar of wax is passed through them and a finished sheet is obtained at the exit.

How to make wax rollers

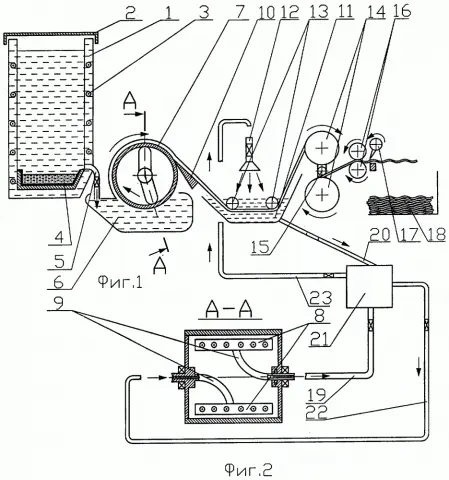

Homemade manual rollers are a convenient and practical thing that does not need electricity. The simplest foundation machine consists of two shafts, clamps that feed the rollers, and a chain drive. All this is attached to the main frame.

Making rollers with your own hands is not an easy task, but with the right skills and tools, you can save from 20000 rubles (the cost of a factory model). In the manufacture, you can use ready-made drawings or make your own. The drawings must clearly show the operation of all moving parts.

An approximate workflow for the manufacture of rollers is as follows:

- Installation of the bed. It can be made from a pipe, a massive profile, etc.

- Installation of a U-shaped profile, which acts as a vertical support for the mechanism.

- A deforming structural element is installed in the upper part. After that, the part is fixed with a threaded clamp.

- Installing the chain drive on the sprockets, tensioning the chain, testing the chain travel, installing the handle for turning the chain drive.

- Shaft manufacturing. The recommended material is hardened steel.

- Formation of the relief surface of the rollers.

- Production of a mechanism for adjusting the gap between the shafts.

- Mounting of the rollers to the bed with the help of rolling bearings.

How to make bee wax at home

To begin with, the rollers are installed in a container with a separating solution. The liquid prevents hot wax from sticking to the rollers and promotes the quality formation of hexagonal recesses on the wax sheet. The solution is usually made by the beekeepers themselves. The recipe is very simple – either liquid honey is used, or a solution of 1 liter of water, liquid soap (about 100 gr.) And 2 teaspoons of glycerin.

The wax manufacturing process proceeds as follows: a wax sheet is placed in a container with a solution so that it stays on the surface, it is carefully directed towards the rollers. Next, they begin to slowly turn the roller handle away from themselves and pass a sheet of wax through the shafts. The surface of the wax sheet passed through the rollers is covered with hexagonal recesses.

In the process of work, it is necessary to ensure that the working surface of the rollers is constantly moistened with a separating solution. The finished foundation is dried, after which it can be mounted on a frame and installed in a hive. After finishing work, the rollers are washed with warm water and dried. It is necessary to store the tool at a positive temperature in a dry room.

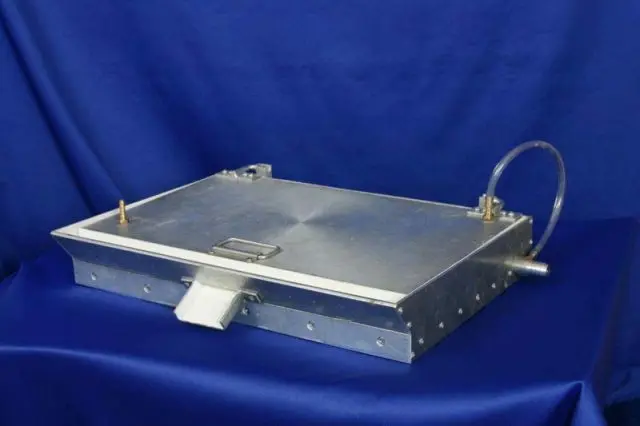

Foundation press

This is a fairly simple device with which you can get a limited amount of finished product (the average productivity of a hand press is no more than 10 sheets per hour). Therefore, in large apiaries, the use of a press is impractical. The principle of operation of the device is similar to a waffle iron – the press consists of two halves with corrugated internal parts. The factory-made press consists of two heavy plates, usually made of aluminum. Between themselves, they are connected with a small gap, which is equal to the thickness of the sheet – from 0,2 to 0,6 mm. Sometimes beekeepers manage to convert old waffle irons into a wax press, fixing silicone matrices for wax inside.

Do-it-yourself wax press

Despite the modest performance, such a waxing machine still enjoys stable popularity among beekeepers. Unfortunately, there are no domestic-made presses for sale, and the price of a foreign tool goes off scale for 50000 rubles. For this money, you can buy good rollers from a or Ukrainian manufacturer. The simplest press can be assembled independently without any problems and costs. For this you will need:

- Beeswax.

- Silicone for mold. Any non-toxic variety of silicone or synthetic raw material that is used to make molds will do.

- Two wooden plates, fasteners for plates.

- Wax sheet – 1 piece.

First of all, they take one wooden plate and a finished wax sheet, a layer of silicone is applied to it. Silicone must be very carefully smoothed over the surface of the wax sheet so that all the cells are filled. Then the silicone is applied to the plate itself and smoothed well. Next, the foundation sheet is covered with a second layer of silicone, smoothed, and connected to a wooden plate with the silicone-coated side.

As a result, the reverse side of the sheet remains clean, like the second wooden plate. They are also treated with silicone in a similar way.

The first layer of silicone is gently smoothed over the surface, after applying the second layer, both wooden plates are connected together so that the wax sheet is between them.

Now you can attach metal loops to the wood-wax “sandwich” and wait until the silicone has completely hardened. You can speed up this process if you place the structure in the oven and hold it for some time at a temperature of 70-100 ° C. Once the silicone is strong enough, you can open the plates, attach the handle and additional side restraint plates. For ease of use, you also need a tank into which excess wax will drain.

How to make wax on the press yourself

Working with the press is very simple: first, the melted wax is poured evenly over the bottom wooden plate with a corrugated silicone surface and pressed with the top plate.

The remains of hardened wax on the edges of the plates can be cut off with a spatula. After that, the plates are unclenched, they wait until the wax has completely hardened, and the finished sheet is carefully removed.

In order for the wax not to stick to the silicone, it is recommended to lubricate the matrix with a solution of laundry soap. However, as practice shows, sometimes the bees build up very bad foundation sheets, on which there are traces of soapy water.

The result is a light, translucent corrugated sheet of fairly high quality. The only possible disadvantage of this design is that the edges of the hexagonal cells can be expressed a little worse, which practically does not affect the construction of combs by bees. Of course, this description of the wax production process is very superficial. In fact, every good beekeeper has his own secrets for making high-quality foundation: special wax preparation, its repeated melting in a wax melter and in a water bath, dehydration, heating the press plates to a certain temperature, etc.

Separately, it is worth considering the process of manufacturing plastic foundation in a press. In fact, it is not much different from the manufacture of foundation from natural material. You will need:

- Silicone (as a plastic substitute) and silicone hardener.

- Spatula, tape.

- Actually, press.

The workflow is the following:

In a separate container, silicone and hardener are mixed in the required proportions. Using a spatula or knife, silicone is applied in an even layer to the matrix, after which it is tightly pressed on top with a press lid. After the silicone has hardened, the finished sheet is removed from the press and kept for some time until the artificial foundation is completely hardened.

Melted wax is applied to silicone with a soft brush or roller. You can also dip artificial foundation into melted wax – it will be faster.

Products made of silicone and other shaping synthetic substances last quite a long time, and silicone matrices in a home-made press will last more than one season. The only condition is not to overheat the form. Thus, using a press even of such a primitive design, it is possible to provide a small apiary with the necessary amount of natural high-quality foundation.

Conclusion

Do-it-yourself wax can be made by any beekeeper who has the desire and enough time for this. This is mainly done by amateur beekeepers who contain a small number of hives. They can afford to recycle excess wax in order to save money and get a quality natural product. Some farms produce colored wax. It is used to make natural multi-colored candles for sale and for interior decoration. People who maintain large apiaries simply do not have time for this, and they buy foundation from trusted suppliers.