Contents

Private houses are increasingly being built from foam concrete. Since the material is relatively new, there are many questions. The first thing you need to figure out is how foam blocks differ from gas blocks. Next, you need to figure out what the dimensions of the foam block are, what density and mass they are. That’s all about it and let’s talk further.

Foam concrete and aerated concrete – not to be confused

There are two porous building materials of artificial origin on the market – aerated concrete and foam concrete. Their composition is similar. It is a mixture of cement and sand with the addition of water and a foaming agent. As a result, the mixture acquires a porous structure, which increases thermal conductivity and reduces weight. These are the main advantages of materials of this type.

But not everyone understands the difference between foam concrete and aerated concrete. It is not surprising: they are very similar in appearance, even they have a common GOST. The difference is mainly in the features of the technology. The characteristics of both materials are very close and they belong to the same group – cellular concrete.

What is the difference

The difference between foam and aerated concrete is the foaming agent used and the order in which it is added.

- In the manufacture of aerated concrete, aluminum powder is added to a dry mixture of cement and sand, everything is thoroughly mixed. Then water is added. As a result of the reaction (aluminum powder with cement components) it forms hydrogen and aluminum oxides. Hydrogen “carbonates” the mixture, resulting in the formation of cells of different sizes – there are large ones – 3 mm or more, and small ones – 1 mm or less. At a low level of production, a non-uniform structure of the block in height is possible. Such heterogeneity is reflected in the thermal conductivity and soundproofing characteristics. Aerated concrete of normal quality has a more or less homogeneous structure and stable characteristics. So when choosing this material, the level of production is of great importance.

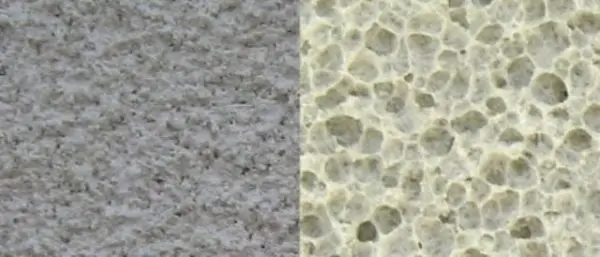

Technology for the production of gas blocks - A chemical or organic foaming agent is added to foam concrete in the form of ready-made foam. First, dry components are mixed, water is added to them, foam is introduced into a uniformly mixed solution, which gives pores of approximately the same size. That is, the foam blocks are more homogeneous in structure (in the photo on the left). In addition, the shell of the bubbles is thicker and more durable.

Production technology of foam blocks

If we consider the materials from this side, then foam blocks have more advantages. But there are other nuances that also need to be taken into account.

Production features

When choosing building materials, especially such as cellular concrete, you need to pay attention to even the smallest details. Because it is they who ultimately affect how warm and durable the structure will turn out. It is these subtleties that we will describe in this section.

- Production technology.

- Making foam concrete is so simple that it can be made in the garage. It is enough to buy a foaming agent, and the rest of the components are readily available. The mixture (cement + sand + water) is kneaded in any container, a foaming agent is added. Next, the composition is poured into molds. The ripening of the blocks occurs in natural conditions – in the air. That is, you can do without special equipment, quality control is conditional – you must adhere to known proportions and technology. But you really want to save money … Therefore, there are a large number of foam blocks on the market, the qualities of which are far from GOST ones.

Foam concrete has a more uniform structure - Aerated concrete is mixed just as easily, but there are two types – autoclaved and non-autoclaved. The non-autoclave also dries outdoors, but does not have the best performance. Autoclaved aerated concrete undergoes a hardening process at elevated pressure and temperature. As a result, blocks are obtained with increased strength. They are more expensive, but much more durable.

- Making foam concrete is so simple that it can be made in the garage. It is enough to buy a foaming agent, and the rest of the components are readily available. The mixture (cement + sand + water) is kneaded in any container, a foaming agent is added. Next, the composition is poured into molds. The ripening of the blocks occurs in natural conditions – in the air. That is, you can do without special equipment, quality control is conditional – you must adhere to known proportions and technology. But you really want to save money … Therefore, there are a large number of foam blocks on the market, the qualities of which are far from GOST ones.

- The accuracy of geometric dimensions.

- Aerated concrete blocks are produced in two ways. According to one technology, the composition is poured into finished forms. These blocks have a difference in size up to 3-5 mm. Using another technology, large-format blocks are formed, which are then cut to the specified dimensions. The difference in the size of such material is minimal.

Strength of foam concrete of different density - Foam concrete is poured into ready-made molds. There is no other technology. Accordingly, the difference in block geometry can be significant. It is corrected by an increase in the masonry joint, which reduces the thermal insulation characteristics of the masonry as a whole. So when choosing, focus on geometry. If the blocks are almost the same (GOST allows deviations of 1 mm), there is hope that the technology was followed.

- Aerated concrete blocks are produced in two ways. According to one technology, the composition is poured into finished forms. These blocks have a difference in size up to 3-5 mm. Using another technology, large-format blocks are formed, which are then cut to the specified dimensions. The difference in the size of such material is minimal.

If we consider these materials from this point of view, then autoclaved aerated concrete with minimal differences in size is more preferable. Masonry from such material is made using special glue. It is applied in a layer of a couple of millimeters, since the ideal geometry allows this. Since a seam with a wall made of this material is a cold bridge, the wall turns out to be very warm (due to the small thickness of the seam, heat is retained in the building better).

When using foam blocks with a large discrepancy in size, a conventional mortar is used for masonry. Glue is too expensive to be laid in large layers. When using cement mortar, the costs are much less, but the thermal insulation characteristics of the building cannot be compared – they are much lower.

Density and mass of foam blocks

Foam concrete can have different densities. It is denoted by the Latin letter D, after which there are numbers from 300 to 1200 in increments of 100 units. The higher the density, the greater the mass and strength, but the lower the thermal insulation characteristics. Therefore, according to the area of uXNUMXbuXNUMXbuse, foam blocks are divided into three categories:

- from D300 to D500 – heat-insulating blocks of foam concrete. They are used as a heater (for example, when insulating a balcony or loggia), they are not able to withstand any significant load.

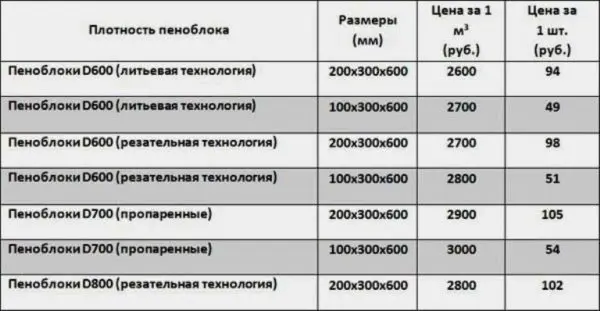

The price of one of the firms. Cut blocks are more expensive, but they are much easier to work with. - from D600 to D900 – structural and heat-insulating blocks. They are also often called construction. They withstand some load, while they have good heat retention properties. These are usually used in the construction of private one-two-story houses. The best choice is D600 and D700. The thickness of the wall when using blocks of this density is only 35-45 cm (for central Russia), and without the need for additional insulation.

- from D1000 to D1200 – structural blocks. Able to carry significant loads, but the thermal conductivity is low. Additional insulation required. Little is used in private construction.

The density of foam blocks affects its mass. In fact, the brand also displays the mass of one cubic meter of material. For example, a cubic meter of D400 brand foam blocks will weigh about 400 kg, a cube of D700 density blocks has a mass of about 700 kg.

Why “about”, because the manufacturing process allows for some error. A little more weight is considered normal – in the range of 10-15%. But at the same time, you need to make sure that there are no extraneous inclusions. Some manufacturers mix broken bricks or crushed stone to reduce costs. Because of this, the mass becomes a little larger, which is generally uncritical. But these additives greatly reduce thermal conductivity, which is not good at all. And this is no longer foam concrete, but incomprehensible building blocks with unknown characteristics and it is not clear how they will behave during operation. So when buying, be sure to be interested in the mass, and if possible, break a couple and see what’s inside.

Foam block dimensions

The production of cellular concrete blocks is regulated by GOST 215 20-89. It defines the characteristics and standard sizes, but there is also a note that it is allowed to change the parameters by order of the consumer.

By appointment, foam blocks are wall and partition. Wall used in the laying of load-bearing walls. They usually have a size of 600*300*200 mm. Some firms produce blocks with a length of 625 mm. The rest of the parameters remain the same. In that case, the size of the most popular foam block looks like this 625 * 300 * 200 mm.

In any case, for a wall 30 cm wide, it is enough to lay one block. Moreover, if you use the brand D600 or D700, it is quite possible to work alone. One block does not weigh that much – from 21 kg to 26 kg (21 kg – less dense, 26 kg – more).

| Foam block dimensions | D 300 | D 400 | D 500 | D 600 | D 700 | D 800 |

|---|---|---|---|---|---|---|

| 600 * 300 * 200 mm | 10.8-11.3 kg | 14,0-14,8 kg | 18,0-19,0 kg | 21,5-22,4 kg | 25,0-26,4 kg | 28,6-29,8 kg |

| 600 * 300 * 250 mm | 13,5-14,9 kg | 18,0 – 19,9 kg | 22,5-24,5 kg | 27,0-28,4 kg | 31,5-34,6 kg | 36,0-39,6 kg |

| 600 * 300 * 300 mm | 16,2-17,4 kg | 21,6-23,7 kg | 27,0-29,7 kg | 32,4-35,6 kg | 37,8-41,6 kg | 43,2-47,5 kg |

| 600 * 300 * 400 mm | 21,6-23,7 kg | 28,8-31,7 kg | 36,0-39,6 kg | 43,2-47,5 kg | 50,4-55,4 kg | 57,6-63,4 kg |

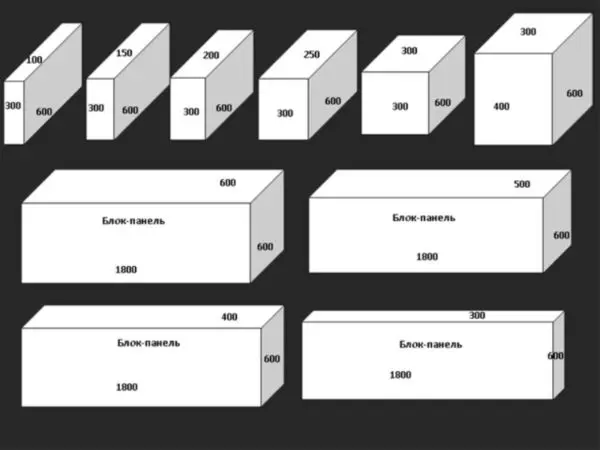

There are wall blocks of different formats. Here are the main dimensions of the foam block, which is used for laying load-bearing walls and partitions:

- 600 * 300 * 200 mm – the most popular size of foam blocks;

- 600*300*250mm;

- 600*300*300mm;

- 600 * 300 * 400 mm.

With a density of D600 or D700, it is quite possible to work alone with foam blocks 200 mm wide, 250 mm wide. Their weight is 20-35 kg. You can handle it alone. Even larger ones, with a width of 300 mm and even more so 400 mm, are already work for two. It is even possible to use a lifting mechanism.

There are large-format block panels. You can work with them only using lifting equipment – at least a winch. But construction is progressing very quickly. The dimensions of the large format foam block are as follows:

- 1000*600*600mm;

- 1000*600*500mm;

- 1000*600*400mm;

- 1000 * 600 * 300 mm.

That is, blocks with a width of 300 mm and 400 mm are stacked in one row during the construction of a building in central Russia. Since their height is 60 cm, there will also be few rows.

There are also smaller blocks. They are usually used for insulation, in some cases for the construction of walls – if the partition is needed with a small thickness, or they decided to build from small foam concrete blocks. The dimensions of the foam block of small thickness are as follows:

- 600*300*100mm;

- 600 * 300 * 150 mm.

It is easy to work with them, since the mass is small, especially if they are used as heat-insulating ones. The density of foam concrete is then 300 or 400 units, so that the weight of one foam block does not exceed 10 kg.