Contents

Wear-resistant materials significantly increase the shelf life of buildings. This is best proved by the floor on the veranda of well-dried tongue-and-groove boards. The material is laid according to the tongue-and-groove principle, so cold and moisture always remain outside the buildings.

Features of the coating

Outdoor terraces are preferred mainly by sunbathers. But in conditions of poor weather protection, the owners of such structures have to use only moisture-resistant coatings. They withstand temperature fluctuations well and retain physical properties for 15 years. In enclosed spaces, this figure doubles.

When choosing materials, be sure to consider:

- Hydrophobicity, that is, the ability to repel moisture. Lightweight vinyl flooring, commercial linoleum and polymer tile win here. Inside the house, they provide high-quality sound insulation, but due to poor resistance to high temperatures, they are not suitable for use outside.

- Hygroscopicity, as a result of which the products are subject to swelling and warping. With timely treatment of the terrace board with protective compounds, its resistance to moisture will increase by 1,5 times. If this is not possible, it is better to make floors on the street from wood-polymer materials.

- Porosity, on which the frost resistance of coatings depends. The leading position here is occupied by clinker paving stones, imitating natural stone, wood and leather. Open terraces are supposed to be sheathed with products with abrasion class V.

- Thermal conductivity. In this case, it is more logical to choose an edged board. It retains heat well, and due to its resistance to decay, it is ideal for private construction. In open structures, deck boards can last longer, which can withstand up to -40 ° C.

No less important selection criteria are fire resistance, coefficient of thermal expansion and, finally, the acoustic properties of floor coverings.

Video “Laying the floor from the edged board”

From this video you will learn how to lay the floor from the edged board with your own hands.

Types of materials

Plastic floors are especially popular. For the price they are available to many. Their other advantages include good resistance to moisture, temperature extremes and mechanical stress. Household linoleum is well combined with the “warm floor” system. And if a kitchen area is provided on the terrace, it is more logical to choose its commercial “brother”. This type of material does not ignite and does not deteriorate under the influence of frequent rearrangements of furniture.

Beautiful flooring involves the use of products of different shades that perform specific functions both indoors and outdoors. For example, saturated red visually narrows the space, and yellow, on the contrary, expands its boundaries.

The device of the floor on the street is unthinkable without cement-gypsum-based materials, with the help of which it is really possible to make a perfectly even coating by hand in just a day. If this is not possible, use OSB-plates with a width of at least 2 cm. Inexpensive ceiling products, due to their low performance properties, are only suitable for completely enclosed structures.

Terrace board

The material is ideal for indoor and outdoor flooring. Its only drawback is its low fire resistance, due to which it is not recommended to buy decking for finishing rooms with barbecues. When in contact with the body, it provides a pleasant tactile sensation, which cannot be said about cold tiles and concrete. Thanks to the corrugated surface, the coating does not retain moisture and does not slip.

The terrace board can be cut with a regular saw, but due to the increased hardness of the material, the work will take a lot of time. It is better to use special carbide discs. These tools contribute to convenient processing of wood and, as a result, quick installation. In the fight against its premature destruction, frost-resistant additives, polyurethane paints and fat-containing compounds will help. Penetrating deep into the pores, they compact the surface of the decking.

Tile

Ceramic products show greater resistance to shock and stress than plastic floors. Unlike wood, they have not only hypoallergenic, but also antifungal properties. And good resistance to abrasion and fading makes them suitable for outdoor flooring.

Sawing ceramic tiles requires certain skills. For beginners, it is better to use a roller glass cutter with a special lubricant that facilitates the processing of hard products. Before their “cutting” it is important:

- draw a cut line with a pencil;

- draw the first strip from the far edge of the tile;

- break the material along the notch;

- file the edges of the product.

A flat surface on a winter veranda can be covered with micropore tiles. For open terraces, satin-type porcelain stoneware is more suitable.

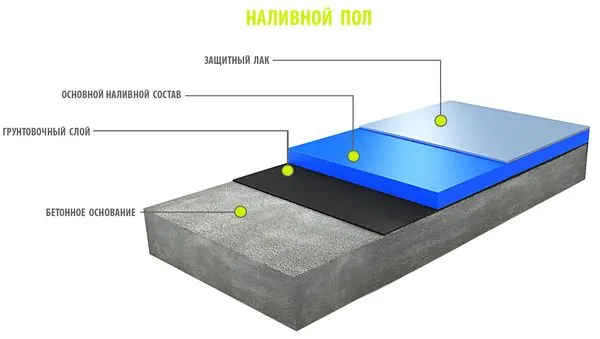

Filling floor

The main advantage of the coating is good adhesion to any substrate. It can be a wooden board, natural stone, linoleum or concrete. The absence of seams and joints simplifies installation, and resistance to high temperatures contributes to high-quality work even outdoors.

Of the shortcomings, it is worth noting the simple design and the need for a perfectly flat substrate. Weather-resistant polyurethane coatings are the best option for an outdoor terrace. They withstand temperature extremes well, but are absolutely beyond repair. Therefore, if the budget allows, for giving it is better to purchase polyurethane-cement coatings with anti-slip impregnation.

Rubber

Modern rubber coatings are 96% natural fillers. They do not contain formaldehyde hazardous to health, so they are ideal for indoor and outdoor installations. Their other advantages include strength, hypoallergenicity and good elasticity. When ignited, the material does not emit toxic substances that provoke burns of the respiratory tract.

Proper care of the rubber coating is the key to its long-term use on the playground and in the gym. Inside the house, dust can be collected with a vacuum cleaner. Wet cleaning with soft brushes is allowed only once every 3 months. On the street, such a floor cannot be exposed to acids and alkalis. To clean surfaces, you need purified water without rust.

Linoleum

The material impresses with a variety of textures and colors. The anti-slip coating is suitable for dance halls, guest rooms and semi-enclosed outbuildings. Due to their low thermal conductivity, such coatings do not cool the heat, and their high hydrophobicity increases their resistance to moisture in fully open structures.

Old linoleum can be painted with acrylics. Unlike oil and alkyd paints, they do not smell and exhibit greater UV resistance. In order for the updated material to last as long as possible, before repair you need:

- remove pile;

- wash the floor with water;

- seal cracks with putty;

- polish linoleum.

DIY flooring

Polymer-based roll products are often laid on a concrete base. Before that, it is leveled with a screed, and if the tubercles are insignificant, a grinder is used. Linoleum can also be laid on a wooden surface. Only for this you need well-dried lumber with maximum resistance to moisture and insects.

The adhesive must be applied in small portions, smoothing the coating with a heavy roller. After a few days, the seams should be sealed and the skirting boards should be filled.

If the pattern is blurry, plain canvases are laid in one direction. You can use double sided tape instead of glue.