Contents

The calf feeder is a container in the form of a box. However, its design has some differences, depending on the purpose of the stern. Feeding troughs for mixed fodder are made with a single trough. For hay, lattice nurseries made of wooden slats or metal rods are used.

Features of feeders for cattle

The capacity for feeding cattle is installed during the arrangement of the stall. Calves are given loose feed and hay. For each type of food, a feeder of a certain design is used. Fresh grass or dry hay is poured into a mounted manger. While eating, calves scatter food, trample it with their hooves. For economical use of hay, rectangular nurseries are made slatted. Calves take only the required amount of food through the cells, and the excess remains in the feeder. Whole containers are used for wet mixers. In home barns, deep plastic buckets are popular. They are hung on a stall.

The feeder should not only be convenient for the calves, but also take up a minimum of space. The most popular are the structures of the angular or hinged type. Manufacturers offer a huge selection of models. It is important to note that feeders for different animals are different. Cattle are suitable for nurseries of the following sizes:

- the optimal length varies from 100 to 120 cm;

- bottom width about 35-40 cm;

- comfortable side height 70-75 cm.

Despite the wide variety of factory products, many owners create do-it-yourself cattle feeders made of wood or metal. The advantage of homemade nurseries are individual sizes. Another advantage is the possibility of improving the design. Craftsmen came up with models with removable bars, folding walls. Collapsible nurseries for cattle are convenient for maintenance. They are easier to clean, wash, dry in the sun.

Types of feeders for cows and calves

All feeders for young calves and adult cattle differ in the type of feed and installation location. There are mangers for hay and loose mash, and they are installed in a stall or on a pasture.

Feeders for cattle for hay

Hay mangers are distinguished by a lattice structure. The stall model is usually rectangular in shape. Often it resembles an inverted cone. The capacity for feeding cattle is equipped with a grate. The calves will pull the hay through the wicker windows. Lattice nurseries in the stall are hung to save space to the maximum. The design does not interfere with the calves, allows access to hay at any time, is easy to maintain, and serves for many years.

Even when cattle are pastured, the calves may not have enough grass. The deficiency is filled with hay. However, you can’t just pile it on the ground. The cattle will trample the hay into the ground. The solution to the problem is the installation of pasture containers for feeding. They similarly have a lattice structure, but increased in size. The shape is given round or conical, which improves the convenience of collective use. The size is calculated to fit a roll of hay. The calves will gradually draw out the dried grass. The roll in the conical container settles as it is eaten. Feed is always available for cattle, and the owner does not need to replenish the nursery with hay often.

Feeders for compound feed and grain

For bulk feed in the form of mash, grain, compound feed, the nursery is made with a solid container. Buckets and rectangular boxes are hung in the stall for calves. Collective troughs of great length are placed on the pasture. Sometimes the containers are covered with a grate on top so that the cattle do not rake out the grain. However, cows often get stuck between the rods and injure their heads. The best option is to abandon the grid. However, the demand for it arises when adult cattle are kept together with calves.

Young growth may not get food. Calves are given separate troughs with restrictive bars, only narrow cells are made. Only a small calf’s head can fit between the bars. An adult animal does not get to feed.

Requirements for feeders

The device of the cattle feeder for hay or grain is simple. However, there are a number of requirements for the nursery, and they must comply with them.

pasture feeders

If it becomes necessary to use a feeder on a pasture, a site is equipped for its installation. Hay and wet food are given in separate nurseries. The following requirements are imposed on pasture feeders for cattle:

- strength and functionality of the structure;

- a container for feeding cattle should not create a hazard;

- collective nurseries require a large capacity;

- must have devices to prevent loss of feed;

- nurseries should be easy to transport, install, maintain.

For dry compound feed or grain on a pasture, it is more efficient to install automatic feeders. They carry out automatic supply of loose feed, provide the necessary norm for each calf, exclude the possibility of losses.

A feeder is in demand for hay during a period when there is a shortage of fresh grass on the pasture. The manger is placed capacious, preferably cone-shaped only in an inverted state. This design works on the principle of an automatic feeder. The hay bale will gradually slide down the sloping walls as it is eaten by the calves.

Stall feeders

On farms, cattle in a stall are serviced manually or automatically by special equipment. Depending on this, the type of stall feeder is chosen. In addition, the number of calves and the way they are kept are taken into account.

The following requirements are imposed on the manger for the stall:

- capacious volume;

- lack of sharp edges that create a danger to cattle;

- availability of simple maintenance;

- the presence of a restrictive wall on the side that prevents the stern from falling out.

In a stall that contains a small number of cattle or one calf, small homemade feeders, such as deep buckets, can be used. On large farms, special tables are used, adapted for the automatic distribution of feed. The device is made by passing along the corrals with calves. Side walls 50 cm high can act as a fence. The table is raised from the floor to a maximum height of 30 cm.

If the type of cattle keeping in the stall is loose, then the hay tables are fenced with one of three types of gratings:

- Straight fences do not prevent calves from moving freely, getting hay at any time they want. The design is considered the most convenient.

- Sloping fences limit the free movement of calves in the stall.

- Automatic fences provide an additional opportunity to fix the calf in one position. The device helps to carry out examinations, medical and other procedures.

Of the three varieties, automatic gratings are the most expensive. Violent calves are able to quickly break them.

How to make do-it-yourself calf feeders

In the household, homemade feeders are usually used. The material of manufacture is metal or wood. Assembling a do-it-yourself feeder for hay or loose feed is available to any owner with minimal skills. However, in the manufacture of a metal structure, welding experience will be required.

In the video, an example of making a manger made of metal:

How to make a hay trough

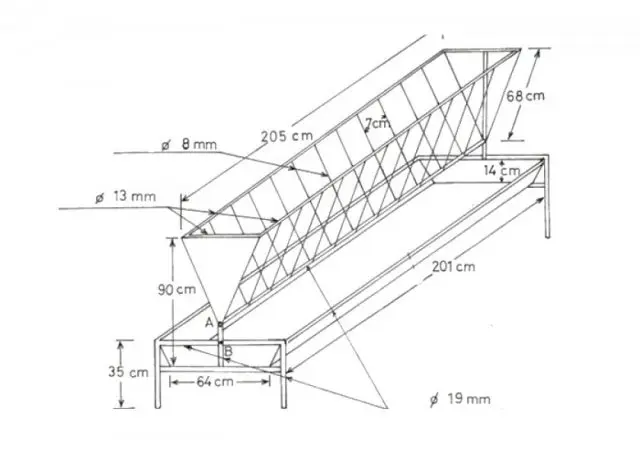

The most reliable hay feeder is a lattice structure welded from metal. A manger can be knocked down from wooden slats, but their service life is much inferior to a steel counterpart. A feeder for a small number of calves is made suspended. For a large number of cattle, collective nurseries are provided. They are usually mounted on legs. The lattice container for hay is welded in the shape of the letter “V”. It is attached to a rectangular base. Often, a pallet is attached under the trellised container to help collect the fallen hay. An example of such a feeder is shown in the drawing.

The metal structure is made of tubes and rods. The frame and legs are welded from a thick pipe with a diameter of 20 mm. The frame of the V-shaped container is made of tubes with a diameter of 15 mm. For the grate, a rod 8 mm thick is used.

Assembly order:

- The pipe and rod are cut with a grinder. The length of the blanks corresponds to the dimensions of the drawing.

- First, a base is welded from a thick pipe. You should get the right rectangle.

- The next step is to weld a V-shaped frame under the hay tank from a tube with a diameter of 15 mm. Vertically welded rods that form the cells of the feeder.

- The rectangular base is connected to a V-shaped lattice structure. On request, a galvanized pallet can be installed.

To protect against corrosion, the finished feeder is painted with non-toxic paint.

How to make a feeder for cattle feed

Compound feed for calves is easier to give in plastic buckets suspended on the wall of the stall. However, for adult cattle, it is desirable to install a solid feeder. It is made in the form of a trough. The material of manufacture can be sheet metal or board. The iron trough is heavy, quickly rusting from wet mash. It is optimal to build a wooden feeder from boards 40 mm thick.

Assembly order:

- From three boards 60 cm long, 15 cm wide, a shield is knocked down. The element will serve as the bottom of the cattle feeder. A shield of the same size is knocked down for the inner side.

- For the outer side, three boards 60 cm long are taken, only the width of two blanks is similarly 15 cm, and the third element is 10 cm. The shield is knocked down so that the narrow board is between two wide ones.

- Side plugs are cut from a wide solid board or cut into narrow blanks, and then knocked into small shields. You should get two rectangles measuring 40×45 cm.

- A trough is assembled from ready-made shields. Elements are fastened with nails or screws.

The finished feeder is subjected to grinding. Sharp edges are cut at an angle of 45 о.

Nursery for young cattle

The process of manufacturing feeders for young calves is similar, only it is necessary to provide for a folding grate that prevents adult cattle from eating food. The length of the nursery is made a maximum of 1 m, the width is at least 40 cm. The sides are set up to 100 cm high.

The best material for manufacturing are boards made of hardwood. The blanks are cut according to the individual dimensions of the drawn up drawing. If we dwell on the established standards, then the feeders of young calves have the following dimensions:

- the height of the inner side – 100 cm, the outer – 30 cm;

- bottom width – 45 cm;

- feeder length – 80 cm.

Having decided on the size, they begin to manufacture a nursery for calves.

Assembly order:

- Dry boards are sanded, sawn with a hand or circular saw. According to the drawing, shields are knocked down from blanks, after which a trough is assembled.

- A semicircular recess is cut out on the side, which makes it easier for the calf to get food.

- Lattices are knocked down from the rails. The width of the cells is selected so that the calf’s head does not get stuck.

Finished nurseries are polished, sharp edges are cut off.

Conclusion

The feeder for calves should be convenient for the animals and the attendants who clean it and distribute feed. In the manufacture of home-made mangers, you need to worry about the strength and safety of using the structure.