Efficient and reliable Baxi heating equipment will provide you with heat and hot water. The Italian equipment differs in profitability, environmental friendliness, exact and silent work. A well-thought-out security system works in critical situations. In this case, the errors of the Baksi boiler may appear on the display. Below you will learn about the meanings of error codes and typical equipment malfunctions and how to troubleshoot with your own hands.

Features of the boiler, the principle of operation

Double-circuit wall and floor devices have a metal case. Thermal insulation layer retains heat and saves energy. There are also single-circuit models that are designed only for hot water supply (DHW).

The device can be connected to a common line and powered by a gas cylinder. Therefore, Baksi boilers are in demand in private homes. The most common models: Baxi EKO four (“Baxi Ecofor”), Baxi Main four (“Baxi Mine for”).

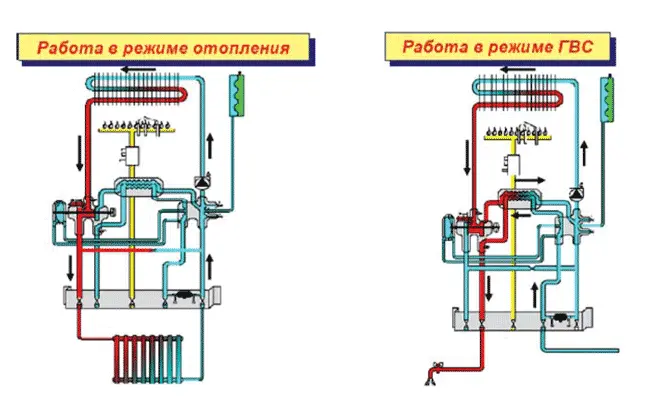

The equipment is equipped with special sensors. So, the temperature sensor measures the temperature in the room. As soon as it falls below the norm, heating starts automatically. The sensor gives a signal to turn on the pump. The burner turns on, heating the coolant. The pump accelerates it along the circuit. The remaining sensors maintain the specified settings, modulate the flame, and control the temperature.

In the event of a malfunction, the system issues an error on the display. The code begins with the letter “E”, which in abbreviated form means Error, that is, an error. A variety of symbols indicates the cause of the breakdown. You can find out about problems in work not only by the code, but also by signs:

- The burner turns on and off.

- Ignition does not start.

- The ignition block pops.

- The system is overheating.

- The water doesn’t heat up well.

- The equipment is noisy.

- Sensors don’t work.

Why the boiler is buzzing, not working or not turning on, how to fix the situation, you will learn further in the publication.

Baxi errors and malfunctions

In addition to our table, the decoding of the codes is indicated in the instruction manual.

| Malfunction code | Which means | What to do |

| E00/E09 | Non-working control board. | Contact the master. |

| E01 | The gas boiler does not turn on. No ignition. |

|

| E02 | Insufficient water heating. The thermostat has tripped. |

|

| Error E03 | For Baxi Main 24 FI means a configuration error. |

|

| E04 | No ignition. Unstable flame in the burner. |

|

| E05 | Malfunction of the heating temperature sensor. | Perform diagnostics of the element, its contacts. |

| E06 | The DHW temperature sensor is out of order. For dual circuit devices. | |

| E07/E36 | Flue gas evacuation sensor defective. | Repair the wiring, install a serviceable part. |

| E08 | Flame signal circuit broken. | Inspect the x4 connector between the electronic module and the power terminal. |

| E10 | No communication with hydraulic pressure switch. The pressure sensor has tripped. |

|

| “Exclamation mark” flashes on the screen | A warning. | Check:

|

| 12E | No hydraulic pressure switch signal. |

|

| E22 | Low voltage in the network (165 Volts). | Plug in the stabilizer. |

| E25/E26 | Problems with the circulation of the coolant. Temperature increase. |

|

| E27 | The DHW temperature sensor is offset. | Put the item back in place. |

| E32. The “Battery” and “Crane” indicators may also flash. | A large amount of scale in the heat exchanger. | Clean up. This can be done with a pump. A professional agent is poured into the pumping tank. You can also pour a solution of citric acid. After that, rinse the unit with clean water. |

| E35 | Parasitic flame. The system receives a signal before the gas valve opens. | Repair the electronic board, gas valve. Check ground connection. Plug in the stabilizer. |

| E40/E41 | The pressure drops. The chimney is clogged. | How to fix:

|

| E42 | The flame is gone. | Elimination:

|

| E50 | The temperature of the combustion products is above normal (180 degrees). | Problems with the circulation of the coolant. Clean the parts from scale. |

| E55 | Incorrect fuel valve settings. | After replacing the board, the settings are not set. Adjust the settings according to the instructions. |

| E62 | Inaccurate signal from the retraction and ignition sensor. | Inspect wiring, sensors. |

| E65 | Frequent start of the chimney function test. | Pressure rises in the gas line. Adjust flame supply. |

| E96 | Low voltage in the network. | Reboot the technique. |

| E98/E99 | Wrong settings. | After installing a new module, parameters F03 and F12 are not corrected. Set up the boiler as instructed. |

| 128 | The flame went out. | Low ionization current. Call the master. |

| E111 | The water temperature reached 95 degrees. | Hold down the Reset key. |

| E129 | Reduced fan speed. | Contact the service. |

| E133 | No fuel supply. | Hold down the Power button for a while. |

| E153 | Enable Reset. | Press this key again. |

| E154 | Water does not circulate. | Contact the service center. |

| 168 | Voltage surges. | This is dangerous for equipment – it is better to put a stabilizer. |

There are such problems:

- St. flashes on the screen. The temperature of the liquid dropped to 2 degrees.

- Flashing LoP. Low pressure in the gas line. Adjust settings.

Some problems are manifested not by the code on the screen, but by other signs:

- Claps when turned on. The gas supply must be adjusted to 5 mbar. Also make a gap between the igniter and the gas pipeline of 4–5 mm. Adjust the flue damper.

- The temperature in the circuit dropped sharply. Blockages in pipes and filters contribute to the problem. This reduces the efficiency of the device, worsens the quality of heating. Clean the parts from salts, rust, plaque.

Now you know how to troubleshoot the Baksi boiler. Watch a helpful video on solving the problem in turbocharged devices: