Contents

- Beekeeping knife: application in beekeeping

- What are the varieties

- Electric honeycomb knife

- How to make an electric bee knife with your own hands

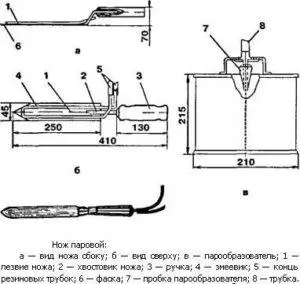

- Steam Knife for Printing Honeycombs

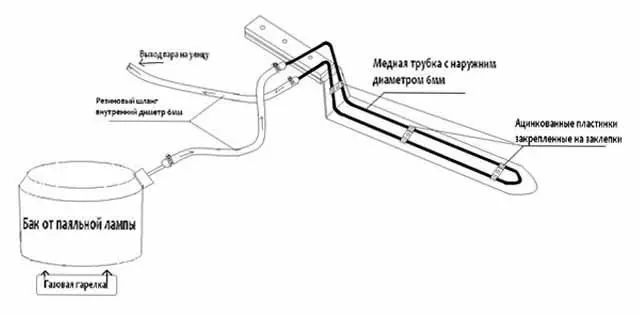

- How to make a steam knife for printing honeycombs with your own hands

- Which knife is better: steam or electric

- Homemade bee knife from a scythe

- Safety precautions and features of working with the tool

- Conclusion

The comb knife has a special shape, and before use it must be warmed up in hot water. The tool is convenient when used in a small apiary. If you need to print a large number of honeycombs, frequent heating in water takes a lot of time. It is more convenient to use an electric beekeeper’s knife or a tool that is constantly heated with steam.

Beekeeping knife: application in beekeeping

According to its intended purpose, a honeycomb knife is used when cutting wax growths from filled frames. The beekeeping tool is made of metal. The blade has a special two-sided sharpening and a pointed tip for easy opening of honeycombs. The shape of the handle is slightly curved. Blade length varies from 150 to 230 mm, width – from 35 to 45 mm. A perfectly flat plane is important. If the working blade is slightly curved, the crumbling of the cast will increase.

During operation, the bee knife is constantly heated in hot water. The heated blade does not stick with wax, which makes it easier to unseal the honeycombs. The inconvenience of conventional bee knives is associated with rapid cooling. You need to have a lot of tools on hand. While the beekeeper works with one knife, the others heat up. The cooled bee tool is changed to a heated one.

To increase productivity, a knife for printing honeycombs is used electric or steam. Constant heating eliminates the need to keep a large number of tools on hand.

What are the varieties

There are three types of apiary devices:

- A traditional tool without heating is heated in a container with hot water before use.

- Steam-heated beekeeping tool. Often they make such a steam knife for printing honeycombs from aluminum, since the heat-intensive metal tends to warm up quickly.

- Electrically heated knife. In a homemade version, often a bee tool is made from an old scythe. There are models with a built-in heater for 220 volts and with a step-down transformer. It is considered safe to use a stainless steel bee knife for printing honeycombs 12 V, since a safe low voltage passes through the blade.

Each model has its pros and cons. The beekeeper individually selects a knife according to the amount of work.

Electric honeycomb knife

The most popular and easy-to-use comb knife is electric, which heats up when connected to a power source. A power tool is more convenient than a steam model, since the heating temperature is easy to adjust.

An electric bee knife 220 V is considered more dangerous, since there is a threat of breakdown of insulators, electric shock. Mostly there are tools that operate on a voltage of 12 volts through a step-down transformer. Such models cannot be plugged into a 220 volt outlet.

The power of the apiary electric knife is adjustable from 20 to 50 W, due to which the heating temperature changes – from 50 оFrom to 120 оC. The approximate weight of the beekeeping tool is from 200 to 300 g. Full heating takes about 1 minute.

Due to the fact that the electric bee knife is automatically heated, the process of unsealing honeycombs is accelerated. The work is going on continuously. During cutting, contact with the wax cools the blade. Heating to the set temperature is carried out during the break, while the beekeeper prepares a new frame.

The quality of the cut will always be good if the blade is kept clean. After work, it is washed with hot water. Be sure to clean off the resulting soot. The blade should always shine.

Store the bee knife in a dry place. No tool case required.

How to make an electric bee knife with your own hands

For a homemade beekeeping tool, steel is required. An old braid or stainless steel sheet will do. First, the blade blank is cut out with a grinder. The length is taken 210 mm for the working part, plus another 25 mm for bending. The width of the workpiece is cut 45 mm. The strip is clamped with clamps, a small cut is made in the center with a grinder. The workpiece is clamped into a tesk. The handle area is heated with a blowtorch. When the metal heats up to a scarlet color, the edge of the strip is bent with pliers.

The handle is made from fiber. First, cut out 2 identical blanks. In one half, a groove is selected where the copper strip is laid, cutting off a piece of the winding of the car starter. The element will serve as a conductor from the knife blade to the wire.

The copper strip is additionally fixed to the blade with screws for reliable contact. The wire for connection to the transformer use a flexible stranded. The cross section is taken about 5 mm2so that it doesn’t overheat under load. The halves of the handle are connected with rivets or screws.

The power source is a 12 volt transformer. You can use a car battery, but it will drain quickly. The heating temperature is regulated by a rheostat. You can change the power by adding or reducing the turns of the secondary winding of the transformer. Reliable insulation is wound between the primary and secondary windings. The transformer housing together with the secondary winding is connected to ground.

Steam Knife for Printing Honeycombs

By design, a steam knife for printing honeycombs resembles an electrical counterpart, only a tube is fixed instead of current-carrying tires. It is connected by a rubber hose to the steam generator. The steam passing through the tube heats the blade and exits in the form of condensate through another hose, put on the second end of the tube.

The advantage of a beekeeping steam knife is a quick warm-up. Water does not get into honey, as is the case with a classic instrument heated with boiling water. The downside is attachment to a heat source to heat the steam generator, for example, a stove.

In the video, a beekeeper homemade steam knife:

How to make a steam knife for printing honeycombs with your own hands

The blade is made similarly to the electrical counterpart. The handle is better to make wooden. Wood poorly transmits heat. The handle will not heat up from the steam passing through the tube.

The blade heater is made from a thin copper tube. It is soldered to the plate using phosphoric acid. The tube should be located on the two edges of the blade. The steam generator is made from an aluminum can or kettle with a capacity of 5 liters. A pipe is attached to the hose. The connection is clamped with a clamp so that the hose is not torn off by steam. The second section of the hose is put at one end on the outlet of the copper tube heating the blade. The other end of the hose is lowered into a bucket or sink to drain the condensate.

Which knife is better: steam or electric

The steam and electric knife have an attachment to the source of energy. In the first case, this is an electrical network with a step-down power supply or a battery. In the second case, the source of energy is a steam generator with a stove or fire. Such attachment is a huge disadvantage of both beekeeping tools.

Which one is better, the beekeeper chooses according to the convenience of work. In terms of ease of use, a factory-made or self-made electric knife for printing honeycombs outperforms its fellow. It is enough to connect the bee tool like a soldering iron to a power source and you can work around the clock. The steam generator must be monitored so that the water does not boil away, otherwise the empty container will burn out on fire.

Homemade bee knife from a scythe

An old scythe makes a good bee knife. The heating element is a soldering iron. To make a blade from a braid, a blank is cut out 150 mm long and 50 mm wide. Drill 2 holes on one side. Rivets and steel clamps fasten the tip of a powerful soldering iron. On the working side, the heads of the rivets are grinded to the maximum in order to reduce their protrusion. The blade is sharpened on both sides. The sting is made a little with a bevel upwards, so that the honeycombs are easier to cut.

The heating of a homemade apiary knife can only be adjusted by selecting the power of the soldering iron. To prevent the blade from overheating, it is dipped in cold water between work.

Safety precautions and features of working with the tool

The opening of the honeycombs is carried out in a closed room, preventing the access of bees. A bee tool of any type is first inspected for serviceability, warmed up. The cut is carried out with fast sawing movements. The blade stuck with wax is cleaned. If the wax begins to burn on the blade, reduce the heating temperature. At the end of the work, the knife is cleaned and put away for storage.

Conclusion

The honeycomb knife cannot be made from ferrous metals. The resulting rust will spoil the taste of honey. If there are no suitable materials, it is better to purchase a bee tool in a store.