Contents

As you know from the legends, if you cut off the head of a hydra, then two will grow in its place. Fortunately, moonshine does not belong to mythical creatures – in most cases, it is enough to cut off the heads of the distillate once. This is done mainly during the second distillation. Let’s talk about her.

This article is purely advisory in nature and applies only to traditional fractional distillation. Here, as in all other articles about moonshine at Romovy, I defend the position that double distillation of moonshine at home is a prerequisite for making quality drinks. If for any reason you feel otherwise, welcome to comment, but it will be difficult to prove to me that a second distillation and crushing of the distillate is inappropriate.

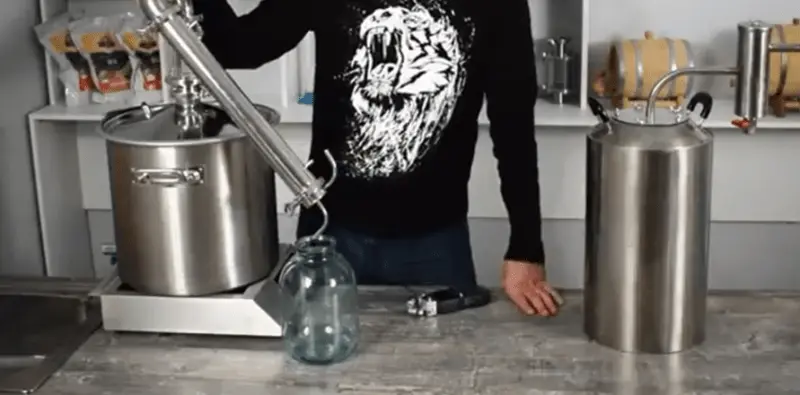

So, if you are reading this article, then you already have a mash. Most likely, you prepared it from sugar, but the second distillation is relevant for almost any distillate – starchy, fruit, etc. We will assume that the mash is ready, fermented well, you correctly prepared it for distillation – clarified it as much as possible (with bentonite, hibiscus and etc.) and removed from the sediment. Pour the mash into the distillation cube, collect the moonshine and put it on fire. At this stage, our main task is to obtain raw alcohol (SS), that is, to squeeze out the maximum alcohol-containing mixture from the fermented raw material and get rid of the insoluble impurities of the mash.

The first distillation of moonshine

We fill the cube by 2/3, maximum by 3/4. The first drops will begin to drip at a temperature in the cube of 88-89оC (this parameter depends on the strength of the mash). Do not forget to turn on the cold water supply to the coil. The first distillation is carried out, as a rule, at maximum power, without the selection of “heads” and “tails”. This is due to the fact that when yeast is boiled, their shells break and proteins decompose. Basically, it is because of this that CC acquires a very unpleasant smell and taste. Accordingly, the longer the yeast “boils”, the more unpleasant the SS will become.

However, the practice is often observed when the heads and tails are cut off during the first distillation of sugar mash. True, the temperature regime is left the same (without a decrease in heating, as is done during the second stage), that is, they are not taken drop by drop. Even with intense heating, the heads come out first – the boiling point of light impurities, which are called “heads”, is about 65-68 ° C. Therefore, it is recommended to collect the first 30 ml from each 1 kg of sugar immediately and get rid of them. For example, during the first distillation of mash from 5 kg of sugar, 150 ml of heads should be selected.

After selecting the heads, we continue the intensive heating of the cube and select the main fraction, in the common people the “body”. If your distiller is equipped with a thermometer, you need to drive up to 98 degrees cubed. After the temperature in the cube rises to 96 ° C, it is recommended to change the receiving container – ideally, the so-called “tails” will start to come out of the refrigerator, in common people “fusel oil”, “fusel oils” – not a food part of the mash, especially smelly and harmful .

For owners of thermometers embedded in a cube, I propose the following table to help:

In general, during the first distillation, tails are taken only from sugar mash. For grain and fruit distillates, they are too important, because it is the heavy fractions, the boiling point of which is higher than the boiling point of ethyl alcohol (above 78 ° C), that determine the taste of the drink. Therefore, grain and fruit mashes are distilled as long as there is at least some hint of alcohol in the stream (usually up to 5%). But there is nothing good in the tails of sugar mash, so it is customary to cut them off already at the first distillation, especially since this does not require reducing the heating intensity. If your alembic is not equipped with a thermometer, sample the body until the CC output is lit or its abv is below 40%.

Tailings after the first distillation do not need to be thrown away. They can be added to the next mash to increase the yield of the product. This process is called tail ringing. Selected heads after the first distillation are better to pour out altogether. As a result, you should get SS of acceptable quality, but not suitable for consumption. Before the second distillation, it is desirable to subject it to purification.

Purification of the SS before the second distillation

After the first distillation, the SS is subjected to the so-called “intermediate” purification. This process significantly improves the organoleptic qualities of moonshine. There are several ways of intermediate cleaning of the SS before the second distillation: potassium permanganate, milk, vegetable oil, activated carbon, etc. I will not go deep into the processes – the most popular methods of intermediate cleaning are described in the manual for the preparation of sugar moonshine.

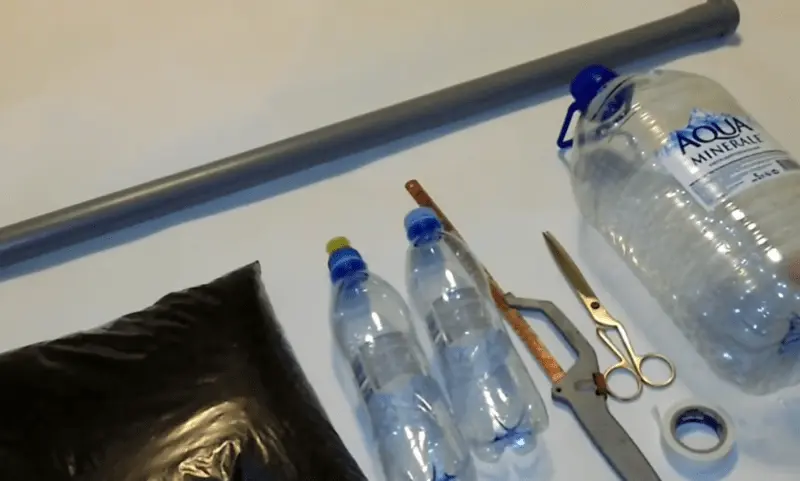

Primitive carbon filter from a plastic bottle

I myself tend to complex cleaning: first with vegetable oil, then with charcoal. To clean with oil, dilute the SS to 15%, pour it into a container with a tight lid and add 20 ml of refined vegetable oil per 1 liter of SS. Intensively mixes 3 times for 1 minute with an interval of 1-2 minutes. After 12-24 hours, carefully drain the more or less pure SS from below – the oil, with impurities dissolved in it, will gather in a uniform film on top of the container. Then we filter the SS several times through any filter: cotton, gauze, coffee, etc. Then the SS must be passed through a carbon filter. Primitive or not – it depends on your imagination. Read more about cleaning moonshine with activated charcoal in this article.

Intermediate cleaning of the SS is applicable not only for sugar moonshine, but also for distillate from starch-containing raw materials. For fruit and berry raw materials, intermediate purification is carried out extremely rarely, limited to only two or three fractional distillations.

Second distillation by classical technology

The principle of the classical technology of the second distillation is not much different from the first, when it comes to sugar distillate. However, some nuances are still present. First of all, if for some reason you have not done an intermediate purification, for example, you are making a fruit distillate, the SS should be diluted to 15-20%. To do this, you can use our alcohol dilution calculator with water. This procedure is necessary for better separation of the distillate into fractions (there is a whole discussion on this topic in the comments to the manual on sugar moonshine).

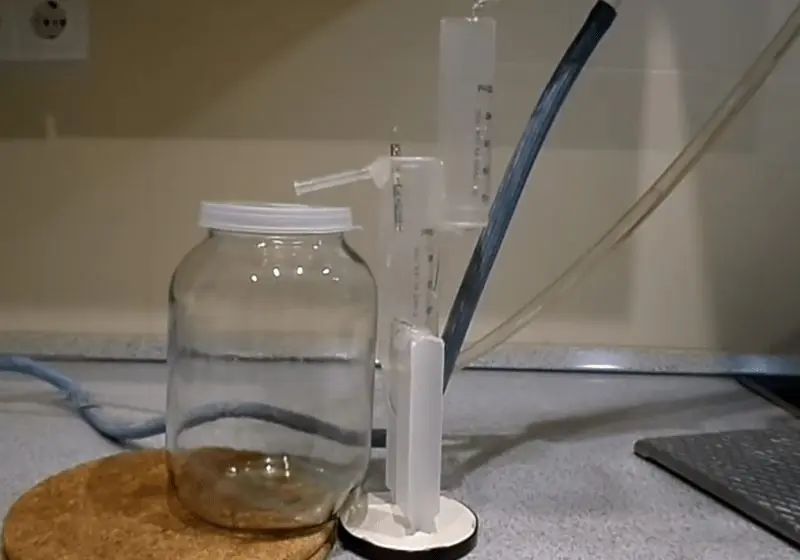

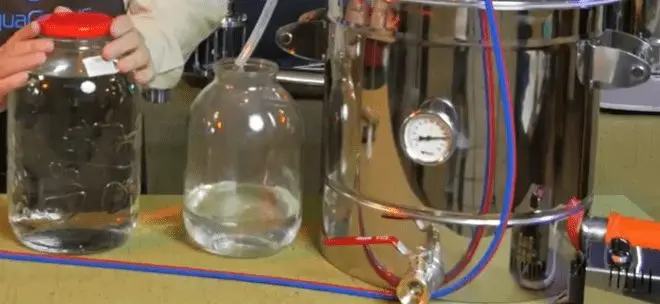

For convenient separation of moonshine into fractions, you can use a “parrot”. With it, you can clearly control the strength of the distillate

We pour the diluted SS into the cube, put it on fire, watch. When the first drops go, we reduce the heating intensity by about a third – it is very important to select the heads slowly, literally 1-3 drops per second. How many heads to select in the second distillation? There are several ways. The easiest, of course, is to focus on the smell. The heads contain light boiling compounds (ethers, methyl alcohol), they smell very sharply, mainly acetone. That’s when the sharp acetone smell disappeared, so you can change the container and take away the body. It is better to rub the “heads” on the wrist or on the palms – this way the smell is captured better.

The principle of operation of the “parrot”

But it is often difficult for beginners to understand the aromatics of a distillate, so it’s easier to focus on volumes. For each raw material they have their own. For sugar distillate, it is enough to select 50 ml of heads from each processed 1 kg of sugar or 5% of absolute alcohol (AC) in SS, whichever is more convenient for you. You can determine the content of AS by banal multiplication. For example, if you distill 10 liters of 20% CC, then we have 2 liters of AC (10×0,2 = 2). It turns out that with 10 liters of 20% SS, we need to select only 100 ml of heads.

But if we are talking about other distillates, then the heads need to be selected “sparingly” – the fewer heads to select, the more floral and ethereal your distillate will turn out.

Therefore, for grain and fruit brews, it is sometimes enough to select 0,5-2% of the AC. True, there are raw materials from which it is better to select the heads to the maximum, up to 10%, for example, in apple distillate, I recommend taking about 8% of the heads from the AC (it is believed that such mashes contain a lot of methanol). It is only at first glance that everything is so complicated – with experience comes absolute understanding.

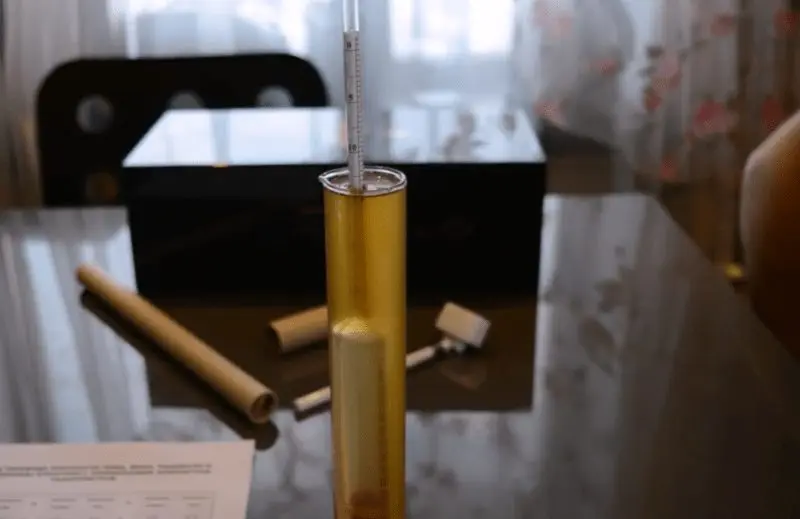

So, they took away the heads – they changed the receiving dishes. If you use a distiller with a dry steamer, replace it as well. After selecting the heads, we increase the heating of the cube, select the body. It is mainly ethyl alcohol, the boiling point of which is 78,3°C. If you made sugar mash, then you need to drive until the strength of the distillate in the stream drops below 45%, after which you need to change the receiving dishes and select the tails. Do not forget that the strength of the distillate, or rather its density, should be measured strictly at 20 ° C. Any temperature deviation leads to a distortion of the hydrometer readings. I would also advise you not to use household alcohol meters for this matter, which in almost 100% of cases will show you anything, but not the strength of the solution, but more accurate hydrometers such as ASP-3. Everything you need to know about alcohol meters you can read here.

For grain and fruit distillates, I recommend using a slightly different “heart” selection principle, more strict. If you are a very, very greedy person, then still stop taking the body when the degree drops below 55%. If you understand that you can’t save on yourself, then stop the selection at 60-65%. Collect tails as long as there are signs of the presence of alcohol in the stream. The collected tails together with the heads can be “ringed”, that is, added to the next batch of SS. Heads of sugar distillate are best sent to the scrap.

So, you just got a double moonshine, which should already be very different from that muddy, smelly goo that you drank in the dashing 90s. Depending on the design of the moonshine still and the conditions for preparing the mash, after the second distillation you will receive about 400 ml of 50-60% distillate from each 1 kg of sugar. It is difficult to say how much it will turn out with 1 kg of fruit or starch-containing raw materials – there are too many variables. In any case, you will receive a high quality product that your friends and acquaintances should appreciate.

Second distillation with “catching” isoamylol

When you comprehend the skill of fractional distillation, you have plenty of “enough” with sugar distillate and others like it, you will definitely come to improve your skills and try something new. The second distillation of moonshine with “catching” isoamyl alcohol is a relatively new technology, which is just gaining interest from our moonshiners. To begin with, I recommend to respect a more than detailed topic on forum.homedistiller.ru. A lot of entertaining reading about the so-called “transitional factions”.

Fractions that are difficult to attribute to both heads and tails are called transitional. Perhaps the most dangerous of the transitional fraction is isoamyl alcohol (isoamylol, izik, IA). In general, I still understand this topic insofar as, therefore, I recommend that you carefully study the material on the forum. But in general, I see the picture as follows. The lower the concentration of alcohol in the cube, the faster the IA evaporates from the mash. Therefore, when we distill, for example, 10% mash, then after 50% distillation, the minimum amount of IA remains in it. This is the essence of the whole technology.

During the first distillation, SS can be collected in a hermetically sealed container – this will reduce the unpleasant smell in the room

Now we put it into practice (we are talking more about grain distillates). During the first distillation, which is intensive and without division into fractions, we select 50% of the estimated yield of distillate. We change the dishes, collect everything else. After that, the first part of the distillation, which is “polluted” with IA, is distilled on a distillation column, better than a film one, with division into fractions, of course (the author of the method does not recommend diluting the SS before distillation). We drive the second part of the first stage fractionally, taking as many tails as we need for taste. In total, we get a tasty distillate and a strong rectified product with a minimum content of isoamylol. They can be mixed or consumed separately.

What to do with double moonshine?

Actually, the main question is: what to do with the resulting double distillate? First, we dilute it to the strength we need, this is obvious. Before use in its pure form, we defend at least a couple of days. Grain and fruit distillates do not need additional purification, or rather, few people do it. Sugar moonshine can be cleaned again, this time with milk, for example. If you want to get an analogue of vodka, pass the distillate through a charcoal filter (homemade or through a water filter jug). There is room for imagination.

Finally, if you wandered into Rum for a reason, you can prepare a huge amount of tinctures, liquors, and liqueurs based on the resulting product. I advise you to look in the direction of imitation of cognac or, even better, whiskey – that’s where you can come off in full. In the end, when you comprehend the zen, when your product starts to be calculated in tens of liters, get a good oak barrel. In general, have fun as you can! 😉