Contents

For normal life support in the house or in the country should be constantly running water. Most often, the sources are a well or a well. Preferably a well. Firstly, because, as a rule, rather deep-lying aquifers with cleaner water are achieved. Second, they last longer. Thirdly, their debit (replenishment rate) is much higher. It is also important that it is possible to drill water wells with your own hands. There are several technologies, you just have to choose.

Methods for self-drilling water wells

Wells for water are drilled or clogged – different technologies involve different methods. Do-it-yourself drilling of wells for water is not possible by all methods, but some can really be used.

Auger drilling

With this technology, a well is made using a special drill – auger. This is a steel pipe, with blades welded in a spiral. When rotating, the projectile plunges into the ground. After it goes to its entire depth, it is taken out, the soil remaining on the blades is poured out. The auger is lowered into the well again, having grown the pipe from above, excavation continues. So, over and over again, taking out the projectile and shaking off the soil, they drill a well. Pipes at the ends can be threaded or connected with studs.

The disadvantage of this method is that it is not suitable for all types of soils. Normally soft or medium hard rocks are drilled. If there is a rocky or rocky layer, the work will be inefficient – the auger is powerless here. Blockages will be observed in loose soils, which is also problematic.

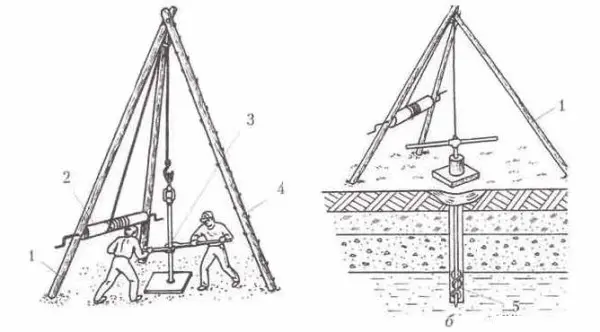

Quite powerful installations work according to this technology, but there are even hand-held auger drills. They work very hard, but possible. There is a simple device that makes auger drilling of water wells with your own hands easier – this is a tripod with a collar and a block fixed at the top. With the help of a cable, a winch and a block, it is easier to get a drilling tool, and this must be done often.

Motorized drilling rigs are more convenient, and not necessarily purchased ones. There are some interesting crafts. In any case, this is a frame with a movably fixed motor that drives the drill. An example of such a setup is in the next video. The auger drill is not used for water wells, but the essence of the installation itself and the principle of operation do not change from this.

With small sizes of the auger and rods, which increase the length (up to 1,5 m), this method of drilling water wells can also be used inside the house, cottage, bath. The main thing is that the soils are suitable.

Hydrodrilling (using a pump or a pump)

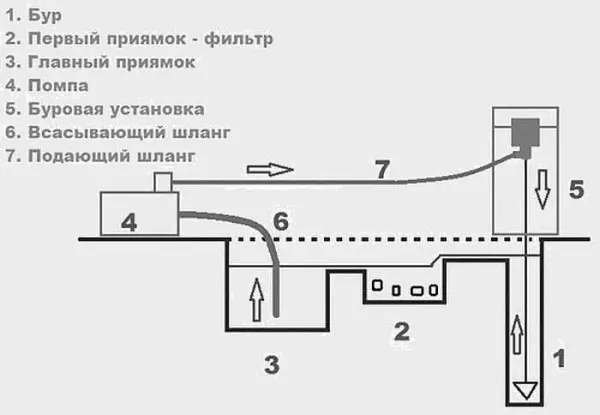

As the name implies, this method uses water to drill wells. When used independently, most often water is pumped into the pipe. It exits through special holes at the bottom of the drill, flows by gravity through the gap between the outer wall of the pipe and the walls of the well.

In addition to a drill and threaded pipes, this method also requires a pump. Before starting work, two pits are dug near the future well. In the first, the main amount of soil settles, in the second, water enters, devoid of most of the impurities. Little water is needed for the process – it constantly circulates. From the first pit, sediments are periodically removed, usually with a shovel. If necessary, if the water has become too dirty, it can be replaced. It is pumped out using the same pump, only it is not fed into the well, but is drained somewhere to the site. Bay a new batch of water can continue drilling.

After the well has reached the required depth, a casing pipe with a filter at the end is inserted into it. Recently, HDPE or PVC pipe is most often used. It is easier to work with HDPE – it bends well. The filter is holes drilled at the end of the casing. The length of such a filter is about a meter. Then you can wind a stainless steel wire on top, and a fine mesh of the same stainless steel on top.

Shock rope method

One of the easiest to implement ways to make a well on your own is shock-rope. But it is also the slowest, in the absence of mechanization, it requires significant physical effort. On the other hand, it can be considered as a simulator. Moreover, it is very effective – almost all the muscles of the body work.

Do-it-yourself shock-rope drilling of water wells is a universal method that can be used on any type of soil. Only the projectile changes, but the technology and installation remains the same:

- On clay and other non-flowing soils, a segment of a thick-walled metal pipe is used, at the end of which a cutting edge is made, beveled inward. It is also called a drill glass for its characteristic shape. It is easy to do it yourself. The main thing is to find a pipe with a thick wall (the thicker the better). It remains to sharpen the lower cutting edge, make slots in the sides (for easy removal of soil), and make “ears” in the upper part for attaching the carabiner and cable.

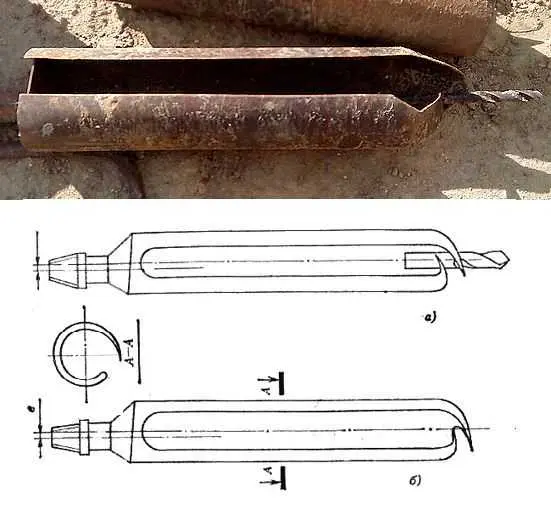

Projectile for shock-rope drilling - In a layer of loose rocks – crushed stone, sand – bailers are used. This is a piece of pipe to the bottom of which a spring-loaded valve is welded. Upon impact, the valve opens, the soil enters the pipe. When lifted under the action of gravity, the valve closes, preventing the rock from spilling out.

Bailer with valve for loose soils - In the same soils, it is sometimes more efficient to use a drill spoon. It is so named for the specific shape of the lower part – two petals bent towards each other.

Drill spoon for viscous soil - A drill bit is used on rocks. First, the rock is crushed, then it is removed using one of the shells described above – whichever is more convenient, this is how they work.

The wireline drilling rig can be implemented in different ways. The most common type is a tripod, in the center of which a block is fixed. But the block can also be attached to an L-shaped structure; an electric motor with a gearbox can also be used to facilitate labor.

The technology of shock-rope drilling itself is very simple: the projectile is lifted, released into free fall. This is repeated many times. With each blow, the well becomes a little deeper. When a section of 50 cm has been passed, the projectile is removed, freed from the ground. And everything repeats again.

To drill faster, you need a heavy projectile. If the pipe walls are thick, the mass can be significant anyway. If necessary, you can make it heavier – fill the upper part of the pipe with lead. Also, to speed up the passage, the lower edge can be sharpened, but this must be done so that the bevel is directed inward. One more thing: pay attention to the slots in the drilling shells. They make it easier to remove the rock. This is especially important when passing dense, viscous clay layers.

A cable for a percussion-rope drilling rig is needed with a diameter of 10-12 mm. If you work by hand, gloves are required. When passing the upper layers, it is easier to use a hand drill, and for easier passage of the upper layers in dry times, you can pour water into the drilled well.

Casing pipe and filter

All the technologies described above for self-drilling water wells have common features. After the well has reached the aquifer (water will appear in large quantities in the rock), they continue to drill for some time, going deep into the aquifer by 1-2 meters. Then the entire drill string is dismantled, and a casing pipe is installed inside the well.

The piping needs to be dealt with. Select the diameter depending on the size of the well you drilled and the type of pump you plan to use. We must carefully consider the choice of material. For some time, asbestos pipes were used for the casing. But they are very harmful – the strongest carcinogen. Do not use galvanized pipes either – zinc is not excreted from the body, it accumulates. And poisoning them has very bad consequences.

There is not so much choice left – pipes made of steel and stainless steel, as well as plastic pipes – HDPE and PVC. Stainless steel is almost ideal, except for the price and complexity of welding. In order for the seam not to rust, welding in an argon environment is necessary, and this is not easy. Although, to some extent, special electrodes for welding stainless steel can help.

In recent years, plastic pipes have become increasingly popular. PVC and HDPE are cheap and cheerful, but for their installation, the well must be perfectly level. Another point – plastic does not tolerate loads very well. Therefore, they can be used at a shallow depth – up to 15 meters. In any case, it is not worth installing sewer pipes for a well, it is still better to find water pipes, although they are more expensive: the walls in them are of different thickness, so investments will be justified.

Steel pipes will definitely not collapse and stand for a long time, but they also have a significant drawback: they rust. Nevertheless, of the options described above, it is the metal that is optimal if there are no funds for stainless steel.

In order for water to enter the casing pipe, a filter is made in its lower part, which is immersed in the aquifer. Holes are made in the pipe. There are two options. The first – with a large diameter drill, in four rows in a checkerboard pattern. The second – longitudinal slots are cut with a grinder (size 1,5-2,5 mm).

A wire (3-4 mm in diameter) is wound on top of the pipe, and a mesh with a very small cell is attached on top of it. It is best to use stainless steel. In this case, it will be possible to wash the sediment filter with washing solutions, and the wire and mesh can be welded to the pipe.

If you use any other metal, after a while the filter will fail. Ferrous metal rusts, the rest are destroyed due to electrolytic corrosion.

Abyssinian well or well-needle

This is a type of manual drilling of wells for water and cannot be called drilling – a special rod with a cast cone-shaped tip is driven into the ground, increasing as needed with pipes-rods (one 1-2 meters long), which are connected by thread. This type of wells is called differently, driven, Abyssinian, needle. All this about one method.

The difference from all other methods is that these pipes remain in the ground, it is through them that water will flow. That is, this is a well without casing. It is pierced with the help of these pipes, and then they are used. Therefore, as the rods with which the needle is built up, water pipes with a thick wall are used. Diameter from 25 -32 mm. Since the pipes are clogged forever, their connection must be airtight. Traditionally, to increase reliability, a winding (usually linen) is used, it can be coated with a sealant.

The first element of the Abyssinian well is called the needle. But the tip-peak is far from the only difference between this piece and others. Holes are drilled in almost the entire length of the pipe. This is a water filter. Water will flow through them. So that they are not clogged with rock, a wire is wound in a spiral over the pipe, and a fine mesh is attached to it. In order for the well to serve for a long time, not to clog, it was possible to flush, the wire and mesh must be made of stainless steel. Only in this embodiment, the filter will serve for a long time and without problems. The use of other metals, albeit stainless ones, greatly reduces the life of the well – metals are destroyed due to electrolytic corrosion. Therefore, brass, copper or any other wire or mesh on a steel pipe is not suitable.

One more moment. So that when clogging the mesh and winding is not torn off, they are welded to the pipe. The next point: the diameter of the wide part of the cone should be wider than the diameter of the pipe. When clogging, the cone leaves a hole of a greater width than the winding pipe following them, therefore it will not be torn off.

The technical process of driving a well-needle is extremely simple: they hit the pipe, driving it into the ground. But if you knock something heavy on the top of the pipe, it will deform. Therefore, they make a special device – a headstock and a cone that is screwed onto the top of the pipe. Inside the headstock, the impact surface also has the shape of a cone. The existing cavities inside are filled with lead – to increase the weight. The more the projectile weighs, the faster the pipe will clog, but keep in mind that you need to lift it with your hands and a lot of times.

The woman herself is much larger in diameter than the pipe that will be hammered. So that during its movement there is no play at the bottom, a washer of a suitable diameter is installed (slightly larger than the outer diameter of the pipe). As a result, the headstock moves freely up / down, but without any backlash. The height of the projectile is determined by its size – it is necessary that it does not fly off the clogged pipe. The appearance of the headstock for driving the Abyssinian well and its drawing are located below.

This is not the only device with which wells are clogged. They make a powerful clamp on the pipe, which is fixed according to the clamp principle. Instead of a headstock, a heavy metal ring with two handles is used. How to work with them – see the video.

As you can see, it is possible to break a well for water inside the house or even at the bottom of an old well. Not much space is needed.

How to equip a punched well

Punching/drilling a well is not enough. We still need to raise the water, and this is a completely different story. How to bring water from the well to the house, read here. If you want to make the water supply constant, with normal pressure, so that you can connect household appliances, you will need a pumping station.

For seasonal water supply in the country, you can get by with a more modest set:

- vibration pump;

- check valve, which is installed in front of the pump;

- water tank;

- watering hose;

- taps, etc.

Please note that the check valve is installed in front of the pump, and not at the end of the hose submerged into the well. Just like that, this very hose will not break during frosts. Another plus of such a device is that it is easier to dismantle for the winter.

Another tip: the well must be closed with something. In permanent residences, a caisson is made – a concrete or plastic bunker, which is located below the freezing depth. It contains all the equipment. When using water only periodically, the caisson is too expensive. But something needs to close the well. Firstly, some kind of living creature may fall into it, which will not please you in any way. Secondly, “good” neighbors can drop something. A more budgetary way out is to build a house like a well. An even cheaper option is to dig a pit, beat it with a board, and make a wooden cover. Key point: all this should be locked.