Contents

Our comfort is largely provided by household appliances. Few can imagine their life without it. A striking example is automatic washing machines. Recently it was a luxury item, today it is almost a mandatory requirement for a normal life. But the technique is for that and the technique to break down from time to time. Naturally, the less often malfunctions occur, the better, but what if the washing machine breaks down? Call the master? If the warranty period is valid – you need to do just that. If the warranty has long ended, you can repair the washing machine yourself. It may not be possible to fix all malfunctions on your own, but most of them for sure.

How is the washing machine

Repairing a washing machine with your own hands is possible only when you know what it consists of, what role each part plays. When the principle of operation and the purpose of each part are clear to you, you can determine from a malfunction what the cause may be. So, let’s look at what a washing machine consists of.

The most common models of this front-loading household appliances – in our conditions, there are washing machines mainly in the kitchen, covered with countertops or in the bathroom. In this case, the front loading hatch is more convenient.

Management

The control unit consists of a panel and a board. On the panel there are knobs or buttons with which we set the washing modes. The board is responsible for recognizing the specified modes. During the washing process, it controls all parts in accordance with a given program – turns on / off the water supply, controls its heating, the operation of the drum, pump for pumping, etc.

All parameters of the machine are monitored by various sensors. The information coming from them is processed in the microprocessor installed on the board. The control system is actually quite complex, but it is she who is the main part of the washing machine. There are the following sensors:

- Water level sensor. Keeps track of how much water is in the tank. According to his indications, the water supply is turned on / off.

- Temperature sensors. Located at the bottom of the tank. According to their indications, water heating is turned on / off.

- Tachometer. Controls the rotation speed of the drum.

- Time relay. Keeps track of required times for various stages.

All these parts are connected to the control board by wires, in some circuits there are relays.

If the board is damaged, the machine starts to confuse programs. This is the main sign that the control board is damaged in the washing machine. All other breakdowns can be associated with incorrect operation of sensors, but program failures are a disease of the processor. The board is rarely repaired, usually it just changes. The bad news is that the cost of the board is high, although the replacement itself is not difficult. The connector for its connection is standard. The old one is turned off. To do this, the conductors are removed from the pads, the faulty board is dismantled. A working one is installed in its place, all conductors are connected in place.

The main reason for the failure of the control board is power surges, so it makes sense to power the washing machine through a stabilizer (or put it on the whole apartment or house).

Executing devices

The control board is connected to all performing devices – a drum, an electric motor, a pump, a valve that shuts off water, etc. It is their work that is monitored by sensors.

- Hatch door lock. Locks the door, when triggered, a click is heard. If the door is not firmly pressed, the interlock relay will not work. In this case, the machine will not start washing. With such a breakdown, repairing the washing machine is simple: push the door, the contacts will close, the washing will begin.

How to change the door lock on a washing machine - Water supply valve. The washing machine is connected to the water supply simply with a hose. Inside, at the inlet, there is this valve, which turns on / shuts off the water supply. If the machine does not draw water (and there is water in the system and the pressure is normal) or vice versa, water is supplied all the time, most likely the valve has “flew”. In this case, do-it-yourself repair of the washing machine consists in replacing the water supply valve. In principle, to begin with, it can be cleaned of salts and contaminants, if this does not help, it will have to be changed.

- Engine. Drives the drum. The rotation is transmitted to the pulley through a belt, but there are direct drive washers. If you have a drum with a pulley, it spins manually, the motor turns on, but the drum does not rotate when it starts, the belt may have broken or loosened. In this case, repairing the washing machine with your own hands consists in replacing the belt. If this problem occurs with a direct drive washing machine, the motor is most likely burned out.

Different types of drives in washing machines - Tubular heating element – heating element. Needed to heat water. If the water does not heat up during washing, but it should, you need to check the health of the heating element, if everything is in order with it, check the temperature sensors. Due to their incorrect operation, water may also not heat up.

- Water pump. This is a small pump for pumping water from a tank. He pumps it out, feeding it into the drain hose.

These are all the main working details. Failure of each of them leads to a malfunction of the washing machine. Repair basically consists in replacing the failed element. Only the pump and the water supply valve can become clogged. There may be a blockage in the lock of the door, it is not accidental – someone can push something there, mainly, of course, these are children.

Washing machine tank

In a washing machine, the tank occupies almost the entire space in the body, since it contains a drum for loading laundry. The drum is movably connected so that it can rotate about a horizontal axis. The heating element and some sensors (temperature, water level) are also located inside the tank; there are pipes on the body for supplying and discharging water.

To hold the tank in one position while the washing machine is running, there is a stabilization system. These are springs and shock absorbers that dampen most of the vibrations.

The tank itself is usually made of plastic. There are collapsible models, there are non-collapsible ones. Washing machines with collapsible tanks are usually more expensive, but in this case it is worth overpaying, as their repair is much easier. If something happened to the bearings, they can be easily replaced by disassembling the tank. Another malfunction of the washing machine in which a collapsible tank is better is a crack in the body. If the shock absorbers do not do their job well, the drum with linen begins to knock on the tank during the spin cycle. Plastic is not designed for such loads, therefore cracks appear sooner or later. If the tank is collapsible, you can change the damaged part. It is not very difficult and expensive. If it is non-separable, in theory, it is necessary to replace it together with the drum, which is not at all cheap. But you can help the trouble in this case too – do-it-yourself repair of the washing machine tank in this case consists in sealing the crack. It is better to use waterproof and heat-resistant universal glue, which can also be used to glue plastic.

Body and other details

Do-it-yourself washing machine repair begins with disassembling the case. The body is usually made of thin sheet metal covered with a layer of enamel. The top cover is plastic, the back is made of galvanized steel, everything is fastened with screws. Where exactly the fasteners are located depends on the company and model. But inside the case there are some more elements.

- Powder supply unit. This is a drawer with several compartments, each of which is filled with its own product. What to pour where, it is written in the instruction manual. For repairs, it is worth knowing that the drain hole may become overgrown in this block. It happens very rarely, but it happens. Then the block is removed (pull it out to the stop, then lift it up a little), coked salts and powder residues are removed, after which the block is installed in place.

The powder feed unit is usually located in the upper part of the housing on the left - Counterweights. So that the tank does not “beat” too much during the spin cycle, it is loaded with concrete slabs of a special shape – counterweights. They are attached to the tank from above and below.

Counterweights in a washing machine are large concrete slabs that stabilize the position of the drum.

These are all the main components of a horizontal loading washing machine. Next, consider their interaction at work.

How does a washing machine work

For self-repair, you also need to know how the washing machine works. This will help determine the element that could lead to this breakdown. So, here is the order of the washing machine:

- When starting the machine, the state of the lock on the door is tested. If the door is closed, the lock is blocked, after which the water supply is turned on (the valve opens). Water is poured through the powder supply unit.

- Water is collected until its level reaches the sensor, after which the valve closes.

- Further, if the mode without soaking is set, the heating element turns on.

- Simultaneously with the heating element, the engine is running. The rotation speed is small, the direction is variable – now in one direction, then in the other.

Main nodes - After a certain period of time (depending on the running program), dirty water is pumped out.

- A new portion is poured. Upon reaching the set level, the drum begins to rotate in different directions – the laundry is rinsed.

- After a few minutes of operation in this mode, the engine turns off, the pump turns on, which pumps out water.

- The last stage is spin. The engine rotates the drum at high speed, while the pump works, pumping out the squeezed water.

There may be deviations in this algorithm – some programs have additional steps. For example, soaking and double spinning. But they are nothing new. Soaking is exactly the same as rinsing, with double rinsing without any problems at all, just water is pumped twice.

Knowing this algorithm will help you determine where, at what stage the failure occurred. Accordingly, it will be possible to determine which parts of the machine could break.

Do-it-yourself washing machine repair: the most common breakdowns

The designs of the machines, although very similar, but there are differences in them. However, there is a certain set of faults common to all washers.

Washing does not turn on

Repairing a washing machine with your own hands begins with the fact that you need to determine at what stage the program stopped. Sometimes the washing machine fails to start. There are several possible reasons:

- Door not closed. Until the relay is activated, the wash will not start. Push the door firmly against the body. If it does not help, there may be a foreign object in the lock or the latch has failed.

- No power or voltage too low.

- Check the integrity of the plug, socket, cord.

The cord may fray - There may be oxidation of the contacts on the terminal block where the power cord is connected. In this case, remove the cover of the washing machine, find the block and inspect the contacts, clean if necessary.

- Time relay defective. Diagnosing a breakdown is not easy. You just need to switch programs several times. If at some point washing starts, then the timer is really faulty.

If all these items are checked, there are no malfunctions, and the washing machine still does not turn on, the problems may be in the control board. This can only be determined by installing the operating board.

Water is not collected

If water is not drawn into the machine, first of all check for its presence in the water supply. It is also worth checking its pressure (open the tap and evaluate the pressure). If it is sufficient, we move on:

- Check the water supply hose. He can be pinched.

- Clogged water filter. Then we act like this:

- turn off the water supply to the machine;

- remove the supply hose from the nozzle;

- remove the filter from the machine with pliers, rinse it under running water;

- set in place, put on the hose.

How to clean the filter on a washing machine

- Clogged or broken inlet valve. In this case, you will also have to turn off the water and remove the hose. But you will still need to remove the cover and get to the valve. It is right next to the intake manifold. We remove it, wash it, check it:

- connect to the inlet hose, in the normal state it is closed, so that the water can be opened;

- we direct the valve into some kind of container and alternately supply 220 V power to the relay windings;

- if there is power, the relay should work – water should appear;

- if there is no water, the winding is faulty, the valve must be replaced.

This is an intake valve.

The same reasons lead to another breakdown – water is drawn into the machine slowly. If the pressure is normal, then either the hoses are pinched / flattened / clogged or the filter is clogged.

Water does not heat up

If the water in the machine does not heat up, the first thing that comes to mind is that the heating element has burned out. In this case, do-it-yourself repair of the washing machine consists in replacing the heating element. But this is not the only reason. There are three of them:

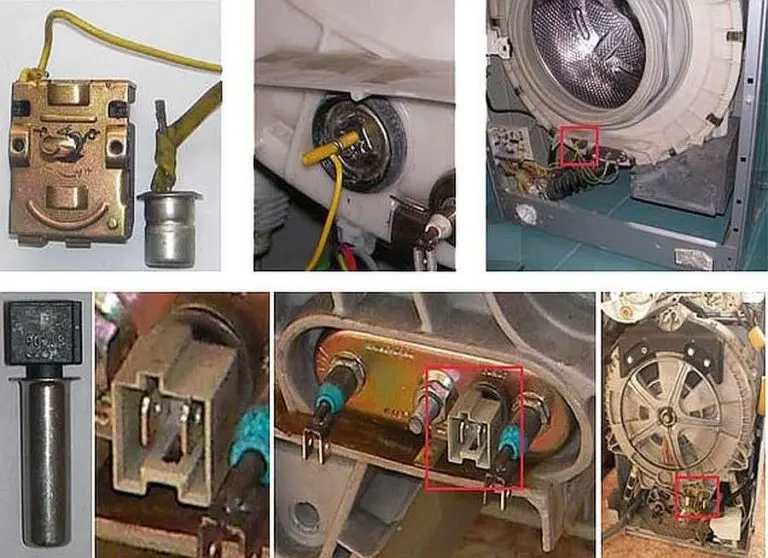

- Faulty water level sensor. The heating element only turns on when there is enough water in the tank. If the sensor incorrectly determines the water level, the command to turn on the heating element is not given. Such a malfunction is treated by replacing the sensor. It happens like this:

- Remove the top cover of the machine.

- We find the water level sensor (pressure switch). This is a small plastic box on one of the side walls of the case. Conductors and a thin tube are suitable for it.

- We unscrew the two bolts that secure the relay, remove the tube (open the clamp). If the tube is hard at the end, cut off the hard part (no more than 12-15 mm).

- Find a tube of the same cross section as soon as it is disconnected (about 10 mm) and 20 centimeters long or more. Put one end of the tube on the fitting, in the other blow. Hold the pressure switch near your ear. If you blew and heard a click, then the relay is working. If there is no click with all efforts, the relay is faulty. It is possible to measure the conductivity of the winding while blowing into the tube. Conductivity changes during operation.

- We install the correct pressure switch in place.

This is a water level sensor (pressure switch). Body color can be any

- The heating element is working, but the contacts are oxidized. In this case, having reached the contacts, they are cleaned to pure metal.

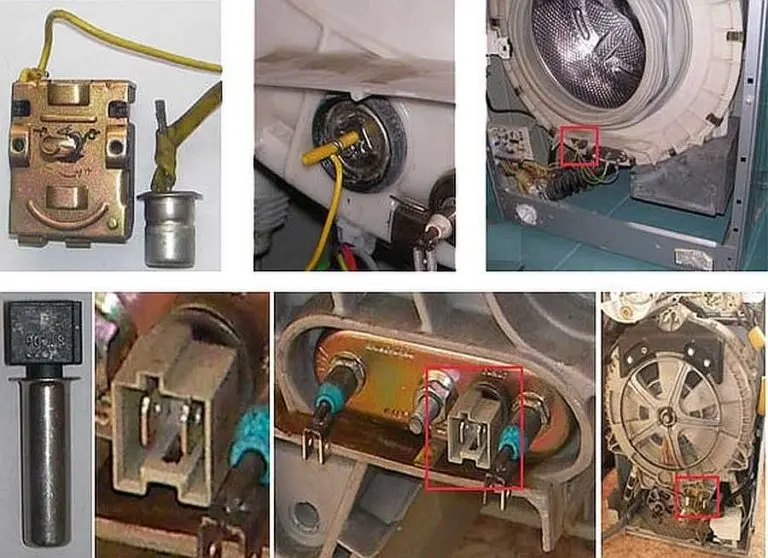

- Thermostat defective. These sensors are located under the loading door. They can be of different shapes, as well as different types: a bimetallic or gas-filled thermostat (looks like a tablet with a diameter of 2-3 cm) and a thermistor (in new models). Having removed the temperature sensor from the tank body of the washing machine, we check it:

- We measure its resistance in a cold state.

- Apply to a pot of hot water, wait a few minutes, re-measure the resistance.

- The difference must be very large. If so, then the relay is working properly. If the resistance has changed slightly, you need to replace the part with a similar, but serviceable one.

If the water in the washing machine is heated, but for a very long time, most likely scale has formed on the heating element. You will have to extract the heating element and clean the scale from it.

The drum is not spinning

There are several reasons again. The first, the most terrible – the motor burned out. To do this, it is necessary to check the presence of voltage at its terminals. If there is no voltage, the motor is faulty. Other problems are not so global:

- The drive belt has slipped or loosened (if the washing machine has a rotary drive). Some models have the ability to adjust the belt tension. To do this, loosen the bolt that secures the engine, pull it back a little, and fix it. It is not necessary to move much – too much tension will lead to rapid wear of the bearings.

- In case of replacement, put the belt on the pulley as follows: pull the belt away from you by hand, turn the pulley counterclockwise. To remove, do the opposite.

How to put a belt on a pulley

Another possible option is that something has got between the tank and the drum that is blocking the rotation. In this case, it is necessary to disassemble the drum and pull out the interfering objects.

Water does not drain

There are a lot of options here. There are too many factors, so this time repairing a washing machine with your own hands can take a lot of time – until you sort out all the reasons … So, let’s start with the simplest:

- Drain hose kinked.

- If the car stops at all, but the indicators are on normally, check if you accidentally pressed “Stop” and the car is in standby mode.

- Faulty water level sensor. We already wrote about it (the item does not heat up water), the check is similar.

- Clogged exhaust filter. It is always located on the front of the case at the bottom right, but, depending on the company, it can be hidden behind a small door (Indesit, Bosh, Sanussi) or behind a removable plastic panel (Sumsung). The filter has a small handle for which it must be unscrewed. Just first substitute the container – all the water that is in the drum will pour onto the floor. We wash the filter and put it in place.

How to clean the exhaust filter of a washing machine - The pump impeller is blocked. When washing, sometimes some small objects get into the tank. They can get between the impeller blades and block it. There is an impeller behind the filter, so first remove the filter. Then, sticking a finger in, we feel for the impeller and check if anything interferes with it. We remove the blockage. It may happen that the impeller is warped. Then you have to change the pump, because it will not work in this form.

Water is leaking from the washing machine

In this case, there are two different situations: it leaks a little and it flows a lot. The reasons are similar, you can check everything. The first thing to do is to drain the remaining water (by unscrewing the filter at the outlet – see the previous paragraph). If it is not clear from where it flows, but not from the door, we start the checks from the simplest:

- We check if the sewer hose has jumped out, if the pipes have clogged.

- We examine the place where the exhaust hose is attached to the car. It is attached to the pump, so you need to get to it. For washing machines Samsung, LG, Candy, Beko, Ariston, Ardo, Indesit, Whirpool, we get access to the pump simply by turning the unit over – the pump is at the bottom. It has a drain hose coming out of it. It may leak at the junction, then loosen the clamp, move the hose a little, tighten it again. Electrolux and Zanussi will have to disassemble the case. It is necessary to remove the cover, then unscrew the back wall (you will have to remove the intake valve by unscrewing the bolts fixing it). There will be a pump and a drain hose.

This is what the drain hose attaches to the pump Next, you will need to disconnect the pump from the wall so that you can get to the drain hose (remember how the pump is attached, or better, take a photo). Further work is similar.

- Drain hose replacement. It happens that the hose cracked, rubbed. Then it must be replaced. You already know how to access the drain hose connection, and replacement is a simple matter. They removed the clamp, pulled the hose off the nozzle, looked where and how the hose is attached to the walls of the car (take a photo), disconnected it. They took a new one, fixed it on the walls, pulled it over the pipe and tightened the clamp.

If it flows from under a closed door, the reason is the wear of the elastic lining.

The machine vibrates a lot

Usually this breakdown occurs at the spin stage. The machine starts to knock and jump. In this case, do-it-yourself repair of the washing machine is rarely required. Most often, the reason is that the machine is overloaded or that the laundry has strayed into one pile, and not distributed over the drum, as it should. It’s simple: stop washing, take out some of the things (if overloaded) or distribute them. Turn on, continue washing.

If none of these reasons is confirmed and the knock becomes constant, the suspension springs may have broken, the shock absorbers have failed, or the ballast mount has loosened. The method of treatment is clear: replacement of suspension springs or shock absorbers, tightening the bolts on the ballast.

Related Videos

There are many possible breakdowns of washing machines, as well as models of washing machines. To describe everything is too long, but in the video format everything is much simpler.

Makina larese nuk starton kur eshte brava e lidhur mirpo kur i preku telat ditekt L dhe C makina fillon te punoj

Makina larese nuk starton kur eshte brava e lidhur mirpo kur i preku telat ditekt L dhe C makina fillon te punoj

Edhe pas vendosjes se braves se re problemi mbetet i njejte