Contents

Modern fishing is inextricably linked with the presence of a boat. It not only simplifies the process of fishing, but also makes it effective. But it is not enough to have a boat, it still needs to be moved to a fishing spot, which can be located at a considerable distance from home. In stores you can find special transom wheels that simplify the process of transportation. It should be noted the presence of various, very expensive products.

But, in order not to pay extra money, you can make such wheels yourself, at home, especially since there are no particular difficulties. They are especially necessary in conditions when fishing is carried out alone, although, as a rule, fishermen go fishing with several people.

Transom wheels for a PVC boat are a transport chassis that is attached using 2 brackets. With the help of these brackets, the wheels are transferred to the transport position or vice versa.

The presence of transom wheels makes the boat more functional. Without outside help, it can be moved along the shore, pulled out of the water and launched into the water. Their advantage is that there is no need to remove them when launching: it is enough to transfer them to the appropriate position.

In the process of arranging a boat with such a device, special attention should be paid to the placement of fasteners on the transom. Their position can affect the maneuverability of the boat, both on water and on land.

Transom wheel functions

The main task of having transom wheels is to:

- Simplifying the process of delivering a boat from land to water.

- Mobility PVC boats, especially on land.

If the boat is equipped with a motor, then it is quite difficult for one person to move it. Not so much hard as uncomfortable because of the significant dimensions. The task is greatly simplified if you have to fish together. If this is not possible, then transom wheels will be assistants.

Their presence makes the process of fishing especially interesting and effective. With the help of a boat, there is every chance to fish in places that cannot be reached from the shore. As a rule, fishing with a boat is always productive fishing and, as a result, a great mood.

The name of the wheels comes from the place of their attachment – which is the transom. The transom is the rigid part of the inflatable boat where the motor is attached. Due to the presence of transom wheels, one person, without assistance, will be able to move the PVC boat effortlessly along the shore, as well as lower it into the water and pull it out of the water.

The main task is to properly and securely fix the device so that it does not fail during the fishing process.

Advantages and disadvantages of having transom wheels

Transom wheels installed on a PVC boat have a number of advantages. For example:

- There are additional conveniences in the process of operation.

- The boat acquires new technical qualities.

- The functionality of the craft is increased.

- Transom wheels take up little space.

- Useful time associated with moving the boat is saved.

- Increases the mobility of the product.

- Simplicity of device and fastening.

- The presence of wheels does not affect the handling of the boat.

- Extra tool life.

The disadvantages of their presence include:

- If you buy them, they are expensive.

To solve this shortcoming will help the independent production of such a useful device.

Types of transom wheels

Manufacturers produce several types of transport chassis. Here are the main ones.

Transformer KT-5

This model has its own installation specifics. The chassis is attached to the transom in such a way that they can not be removed when transporting the boat in the folded state. This design has additional advantages associated with ease of movement. When moving on water, they do not affect its maneuverability.

This chassis model allows one person to move the boat from place to place without much effort.

The main construction material is steel, 3 mm thick. As racks for wheels, a profile pipe of a special configuration is used. This allows you to quickly install the device and transfer it from the transport position to the working one.

In addition, the wheels have a spring mechanism that allows you to transport the boat on uneven surfaces.

Automatic KT-3N and KT-3NU

The main material for the manufacture of such devices is stainless steel. Models are intended for inflatable boats with a rigidly fixed transom or for boats that have a rigid hull.

Benefits of auto-commit:

- The device is made at a high technical level.

- Has high reliability.

- Features a modern design.

- It can serve as the best option when moving the boat over long distances.

- Easy to operate.

In the production of automatic CT devices, laser cutting is used, followed by argon welding. As a result – high accuracy, excellent quality and acceptable appearance.

These wheels can withstand a watercraft in running order weighing up to 120 kg.

Folding transom wheels

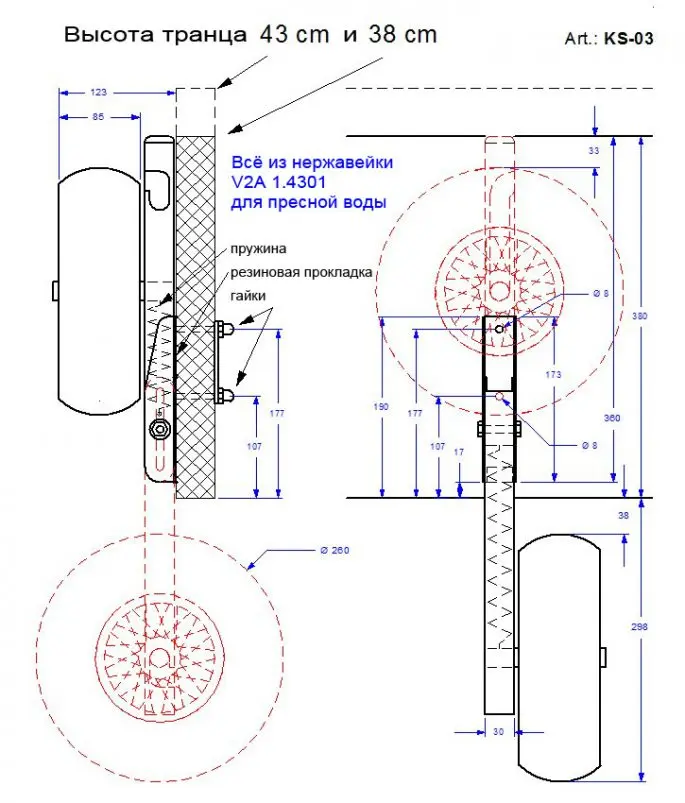

The device is mounted on the outside of the transom, which allows you to easily fold the wheels from the bottom up. To fix the product, springs are used in the design, which are located inside the racks and made of stainless steel. It should be noted that the rest of the folding wheels are made of stainless steel, which provides the structure with enviable strength and resistance to both fresh water (KS-03) and salt water (KS-04).

The advantages of such a model:

- Easy to install, remove and operate.

- There is no need for constant removal and installation of the chassis.

- The method of fastening does not interfere with the control of the vessel.

- There are packaging options along with installed wheels. Can be installed on any PVC boat model. Withstands loads up to 180 kg.

Tilt and turn landing gear, for PVC boats

Such designs are focused on transporting the boat by one person over short distances. They are mounted with 4 bolts to a plywood transom. It is possible to adjust the height of their installation due to the length of the mounting stud.

To remove the fixture, just unscrew the nut, which is located on the side of the rack. The wheels are designed to move weight up to 140 kg.

The main parts are made of stainless steel, which indicates the strength of the product.

Do-it-yourself transom wheels for a PVC boat.

Making transom wheels with your own hands

The size of the structure must match the size of the boat. The main task is to make sure that the chassis does not interfere with the maneuverability of the craft.

For manufacturing, it is necessary to prepare such materials and tools:

- A pair of wheels with a diameter of 350 mm and a width of 60-80 mm.

- Profile pipe, section 25×25 mm from stainless steel.

- A pipe of suitable thickness for mounting wheels.

- Fasteners: nuts, bolts, washers, etc.

- Hacksaw, electric drill, grinder, wrenches, pliers, etc.

Stages of manufacture:

- The place of installation on the transom of a square profile is determined (so as not to interfere with the operation of the engine).

- Measure the distance down, paying attention to the fact that the wheels should be installed just below the lower edge of the transom, taking the radius of the wheels as a basis and adding 5 cm. This is the most optimal arrangement of the wheels, which will not affect the running capabilities of the watercraft.

- The bracket where the wheels are mounted can be made both at a right angle and at a different angle. A right angle bracket is most preferable, since its installation takes a minimum of time. In addition, this element is able to withstand heavy loads.

The second option is more technologically advanced, but also more optimal, since the wheels are placed under the bottom of the boat and do not interfere with the operation of the outboard motor.

To do this, 4 pieces of the required length are sawn off from the profile and by welding they are attached to the bottom of the profile. A through hole should be drilled in the tubes so that the rings can be fixed. In addition, a nut of the required diameter is welded to the inside of the tube ring so that the product does not press against the fastener.

From the outside, it is better to install plastic or rubber plugs so that water does not get inside.

In the upper part, 2 through holes should be drilled, which are provided for mounting the chassis to the transom.

The two parts of the mount are welded together. The angle between them can be 35-45 degrees, otherwise the ends are adjusted.

After that, as all the preparatory work has been done, the chassis is installed on the tubes and clamped with nuts and washers. So, the device is ready for use. If necessary, the design can be painted. If the material is stainless steel, then this is not necessary.

Drawing

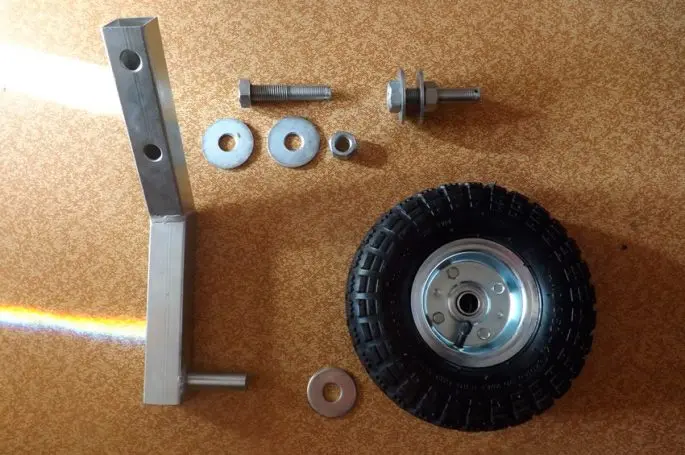

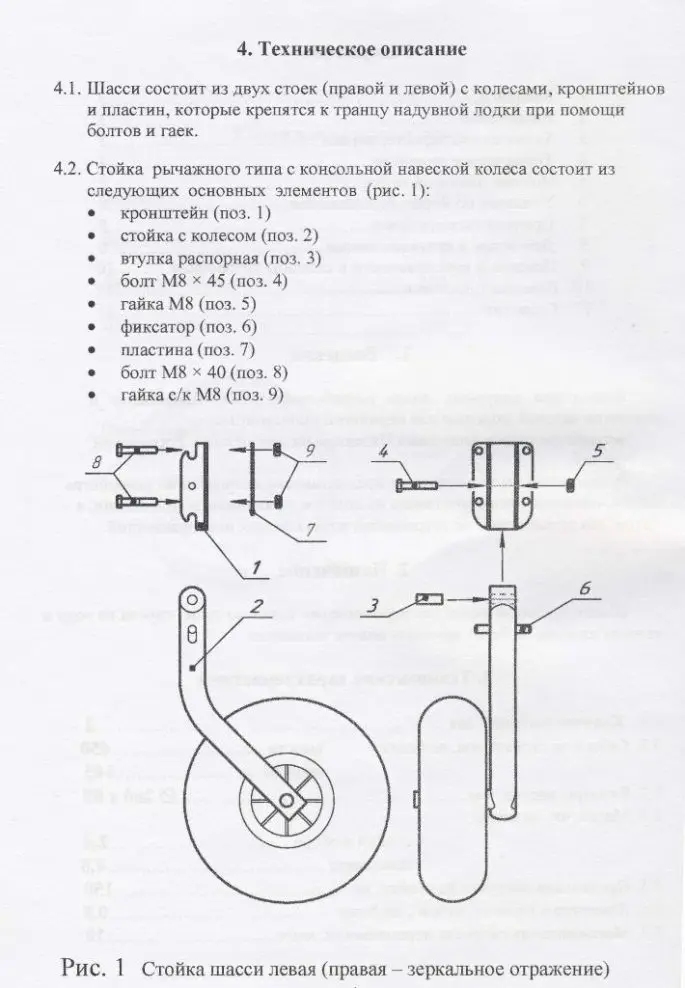

Elements of construction

Do-it-yourself transom wheels for PVC boats from scratch!!!

Mounting methods

Several mounting options are possible. At the same time, some recommendations should be followed, such as:

- The mount is placed on the transom and marks are made along the holes with a pencil. After that, holes of the desired diameter are drilled strictly in the center.

- The following steps are similar, but holes are drilled on a sheet of durable material such as textolite, aluminum or duralumin. This sheet is applied to the inside of the transom and holes are marked with a pencil, as in the previous case.

- It is better to install bolts from the inside of the boat so that the nuts are on the outside.

- The wheels are attached with bolts, nuts and washers.

Some recommendations:

- For ease of transportation, it is desirable to use transom wheels.

- The finished product costs a lot (comparatively) of money, so the best option is to make the chassis yourself. Firstly, it is inexpensive, and secondly, it is interesting.

- All fasteners and parts of the fixture must be made of stainless steel. But this is ideal. If this is not possible, then it can also be made from ordinary metal, but then you will have to carefully cover the structure with paint or waterproof varnish.

- Install the transom wheels very carefully so as not to damage the boat itself. After all, this is a very expensive thing that will then have to be repaired.