Contents

If there is more than one floor in a private house, you cannot do without stairs. But besides the fact that it must connect the floors, the staircase must also fit into the interior. Therefore, when choosing a design, it is necessary to pay attention not only not to the dimensions and how much space it takes in the room, but also to take into account the style. Then the staircase to the second floor, made with your own hands, will be not only a functional item, but also an interior decoration. The work is difficult and responsible, but it can be done.

Types of stairs to the second floor in a private house

If we talk about the device, then there are three types of interfloor stairs:

- Screw or spiral. They take up the least space, look good, but are not very convenient to use. Most often used as supplements.

The most compact interfloor stairs - On the pains. The steps are mounted on special metal bolts – bolts. There are no heavy fasteners in the design, which visually makes the structure look light.

Stairs on the bolts – they look very interesting - Marching. The most common type. May consist of one, two or more marches (elements). If there are several marches between them, platforms are made – turning or not – depends on the choice of the owners, but is mainly determined by the dimensions of the room and the allocated area.

There are two types of marching ones – on stringers and bowstrings

All these structures can be made of metal, wood, concrete, glass, marble and other decorative stones, and often use combinations of these materials. But most often the staircase to the second floor is made of wood with your own hands, a little less often – from metal or combinations of metal and wood.

In addition, there are two types of degrees – open and closed. In open stairs there is only a horizontally located part – the step itself, in closed ones – there is also a vertical part – risers.

Design codes

When designing a staircase, it is important to make it comfortable and safe. There are very specific numbers and recommendations that relate to the parameters of the steps and the general angle of ascent:

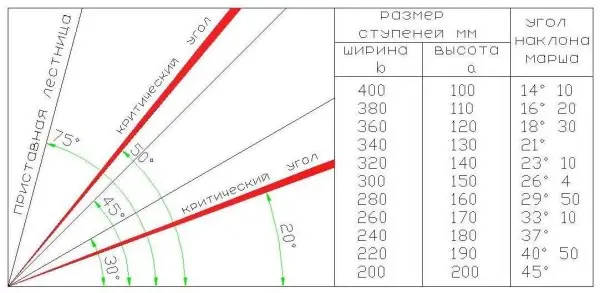

- The angle of inclination should be within 30-50°. The optimal inclination is 45 °, at a smaller angle it is convenient to walk, but a lot of space is required, at a larger one, too steep a rise causes difficulties.

It is desirable that the angle of inclination of the stairs fit into this sector. The table shows the standard dimensions of the tread and riser for each angle of inclination. - The number of steps is odd.

- The width of the step (tread) is in the range of 22-30 cm. The most convenient steps are about 25 cm wide – you stand on them with your whole foot. With narrower ones, the heel hangs, and the main load falls on the toe.

- The height of the riser (the distance from one step to another) is 15-20 cm. If the height is too low, you often have to rearrange your legs, which is uncomfortable, if it is large, it is difficult to raise your legs (especially for older people).

- Railing height 90-120 cm.

- The minimum width of the stairs is 80 cm.

The number of steps is determined by simply dividing the height of the planned staircase by the chosen height of the riser. For example, the height of the room is 285 cm. It was decided to make the angle of elevation 40°. According to the table, we see that the height of the riser is 19 cm. We divide 285 cm / 19 cm = 15 steps. If the number turns out to be even, we slightly adjust the size accordingly to get an odd number.

If one of the steps turns out to be several centimeters smaller, this height is “taken away” from the first step. All others, including the last one, should be the same.

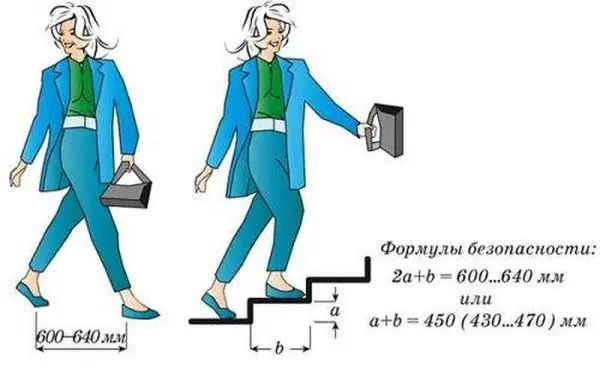

When choosing the size of steps, comfort can be checked. If the double height of the riser is added to the selected step width, the result should be from 60 ms to 64 cm. The second test option is that the sum of the lengths of the tread and the riser is optimally 45 cm, but deviations of 2 cm in both directions are acceptable.

All these parameters should be taken into account when designing a house. If the house has already been built, you have to proceed from the fact that there is and adjust the dimensions to the existing dimensions.

Spiral staircase

As already mentioned, a spiral staircase in a private house takes up the least space. But she has a serious drawback: it is inconvenient to walk on it, and it is almost impossible to lift anything bulky to the second floor. So they are not very popular, although they look good and fit well into any interior.

Calculation features

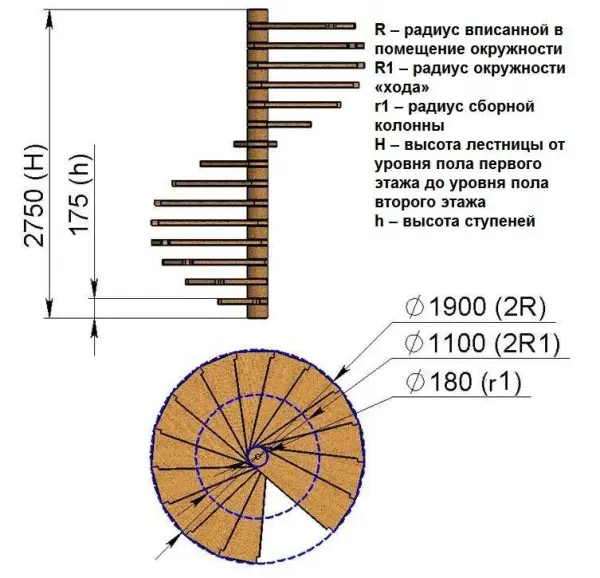

When designing a spiral staircase, one must take into account that in some positions, there are other steps above the head. Therefore, making small risers will not work.

The next feature is that the steps all have an unequal width – narrower on one side, wider on the other. The narrow part they are attached to the central support (pillar), the wide part – to the walls or balusters. The standard for the width of the tread is measured in the middle part, and the wide one should not be more than 40 cm.

The span width is from 50 cm to 100 cm. Double the distance goes to the entire structure – a square with a side of 100 cm to 200 cm is required.

Construction on a prefabricated column

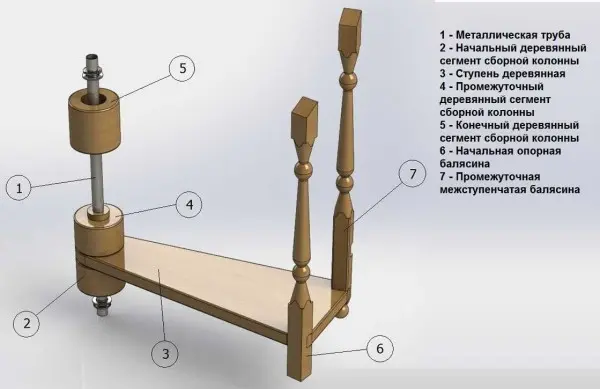

This type of spiral staircase is the easiest to make: a pipe is placed on which wooden elements are put on – steps, intermediate cylinders, etc.

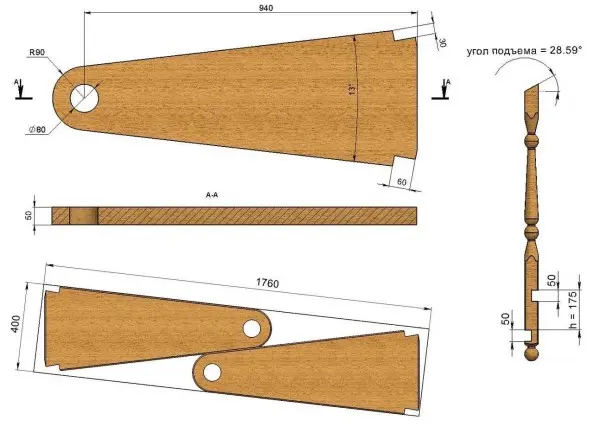

If you look in more detail, then in addition to the metal pipe (in this case, 40 mm in diameter), steps and balusters (available in any design), there are turned wooden cylinders (segments) that set the distance from one step to another.

On the other hand, the distance between the steps is kept with the help of cuts on the balusters. Steps are attached to these grooves (on glue + fasteners).

Do-it-yourself installation of stairs to the second floor begins with the installation of a pillar. In the floor of the first floor and the ceiling of the second, a hole is made equal to the diameter of the pillar. We insert the pipe into the hole, put on an enlarged washer, tighten the nut. Further, the assembly is simple: the corresponding elements are mounted on the rod, in parallel with the installation of the step, the baluster is placed and fixed. The dimensions of the steps for this spiral staircase with the given parameters are in the drawing.

Steps are cut from glued board or furniture board. You can use an array, but of furniture quality, that is, without any defects and dried, with a moisture content of not more than 8-12%. Although glued wood is considered more reliable: it definitely will not lead and it will not crack during shrinkage.

An example of an assembly of such a design, see the video. It has a prefabricated post, but you can also use a solid one, although it will be inconvenient to assemble the steps – you will have to climb the stairs every time.

The design of a metal spiral staircase is presented in the following video fragment. For those who are friends with welding, this option will be easier.

Spiral staircase to the second floor: photos of interesting options

Staircase to the second floor

Marching stairs are the most popular. Firstly, they are convenient to use, and secondly, the technology of their construction has long been worked out. There are few features of the calculation. It is important to determine the number of marches. In one section there should be from 3 to 15 steps. The most convenient have 11-13 pieces. If, according to the calculation, it turns out that there should be more steps, they are divided into several sections, between which platforms are made. The dimensions of the platforms are a multiple of the step length (600-630 mm). Then the ascent and descent will not cause inconvenience.

Types

Ladders with platforms take up quite a lot of space. If there is not enough space, add turns. The most common option is to place the stairs along two adjacent walls at the corners. Also, to save space, you can make winder (turning) steps instead of a platform. Only one point: the section with winder steps is the most traumatic. If the family has small children or elderly people, it is better to make a playground.

As mentioned earlier, mid-flight stairs are made on stringers (beams with a sawtooth edge) and on terraces (just an inclined beam). Fastening steps to bowstring beams requires more time and skill. Usually, a “seat” is cut out for each step – a groove is selected in the board. For additional reliability, bars are still nailed from below or corners are installed. The option with corners is reliable, but rather controversial from an aesthetic point of view. If the whole staircase is made of wood, the metal parts are very “cut” the look. Carefully processed bars look much more organic. However, with sufficient thickness of the boards for the steps and the width of the bowstring, you can do without additional fasteners. In this case, it is important that the steps do not bend, otherwise they may pop out of the grooves.

The assembly of steps on stringers is simpler: you have two or three supports, to which parts cut to size are attached. The main task is to correctly mark and cut out the stringers.

Installation of a marching staircase with step by step photos

Stringers are made from a wide board 75-80 mm thick and 350-400 mm wide. If there is no massive dry board, glued boards can be used. How to calculate the kosour is described in the form, but it is possible to assemble a staircase to the second floor not only as a separate one.

An example of assembling a ladder on the stringers next to the wall. First, we fix the support pillars on which the winder steps will rest. We attach the upper stringers to these pillars.

Then we put the bottom. We fasten the kosour near the wall on top of a decorative board – it is easier to wash it and the dirt is less visible than on the wall.

Intermediate stringers are installed last. This makes it easier to connect all the elements.

The steps are being installed. After they are cut, sanded and painted, everything is simple: put in place, drill a hole for a self-tapping screw, then twist it.

The next step is attaching the balusters. In this case, they are made of stainless steel pipe with wooden inserts. A hole is drilled under each baluster, into which a tube is inserted, it is fixed on a hairpin or in any other available way.

Photos of interesting mid-flight stairs to the 2nd floor

Bolts stairs

The most unusual in appearance are the interfloor stairs on the rails. Bolts are a special type of metal fasteners, which are attached to the feet with one edge, and to the support with the other.

The design turns out to be very light in appearance, but the bearing capacity of such devices is considerable – about 220 kg.

On one side, the steps can be attached directly to the wall (also on the bolt), as well as to the bowstring or stringer. The opposite part is usually attached to a frame fixed in the interfloor ceiling. This is the carrier element. Bolts descend from it, which are then attached to some part of the steps. Those that were without support are kept due to the redistribution of the load. Independent calculation and design in this case is very problematic, it is more reliable to order the development of the project.