Contents

- Manufacturing Benefits

- Types of structures

- Balloon selection and preparation

- How to make a smokehouse from a gas cylinder with your own hands

- Do-it-yourself hot-smoked smokehouse from a cylinder

- Model Selection

- Dimensions and drawings

- Preparation of tools and materials

- Assembly algorithm, assemble the firebox

- We assemble the upper cabinet of the smokehouse

- Cold smoked smoker from a gas cylinder

- Model Selection

- Dimensions and drawings

- Preparation of tools and materials

- Site selection and preparation

- Assembly Algorithm

- Do-it-yourself smokehouse from a freon cylinder

- Finishing and painting

- operating rules

- Photo ideas of do-it-yourself cylinder smokehouses

- Conclusion

Creating a cold and hot smoking apparatus does not require any outstanding knowledge or skills. It is only required to make a reliable case and a smoke generator. It is with the body that the main problems arise. Therefore, they use ready-made metal containers, it turns out quickly and reliably, for example, a do-it-yourself smokehouse from a gas cylinder can be made in a day, while building an apparatus from scratch will take at least 3-4 days.

Universal smokehouse model from a cylinder of high performance

Manufacturing Benefits

In theory, a smokehouse can be built from any metal cylinder that is suitable in size, but it is gas containers that are most in demand among do-it-yourselfers. There are only two reasons for such sympathy and preferences in favor of gas models:

- A suitable cylinder volume, usually 27-50 liters, is more than enough for a household home smokehouse;

- Increased wall thickness. On average, the walls of a gas tank for propane are made 4-5 mm thick, for oxygen cylinders the thickness reaches 9 mm.

At first glance, what difference does it make, for any container, even if you take a cylinder from a boiler or a hydraulic accumulator, the body metal will withstand the heat load in cold or hot smoking conditions.

But this is only at first glance, in practice, when making a smokehouse with your own hands, cold smoked or hot, it doesn’t matter if you need to cut a window of a sufficiently large size in the side wall or from the end. Otherwise, putting food inside will be very inconvenient.

Models of smokehouses with bottom loading, despite the simplicity of design, are not popular

All other containers of a similar device, the same boiler or hydraulic accumulator, aluminum cylinders for air filters lose their stability after cutting and can be crushed even with a slight mechanical load. In theory, you can make a smokehouse from a hydraulic accumulator, but it will be extremely inconvenient to work with it.

Types of structures

The range of home-made smokehouses from cylinders can be conditionally divided into four large groups:

- Two-hull design with a horizontal hot-smoked chamber on wood;

- Cold smoked smokehouse with two bodies and a vertical chamber;

- Single-case vertical smokehouses of hot smoking on wood;

- Electric smokers.

The design and layout of the smokehouse of the same type may differ, although the same principle is used for processing products with a mixture of air, steam and smoke obtained in a separate device – a smoke generator. Therefore, to make a cold-smoked smokehouse with your own hands from a cylinder, you will need three containers. For hot smoked machines, you can get by with two or even one large-capacity cylinder, for example, oxygen.

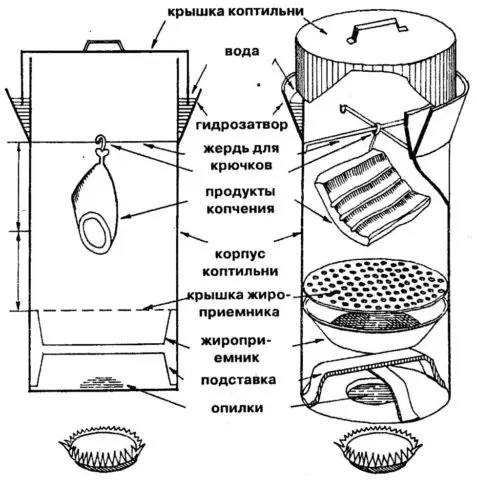

Schemes and models of hot smokehouses

The most common option is two cylinders or a couple of steel containers connected to each other through a control valve or a metal elbow.

A good hot smoked smokehouse always consists of three blocks:

- Capacity or a small cylinder of a smoke generator;

- Chimney with damper;

- A horizontal block of a large propane tank.

Smokehouse from three cylinders

Moreover, often the inner surface of the cylinder is cleaned to a shine or lined with stainless steel sheet. The metal is well washed, so it is possible to avoid the smell of old burnt fat that is released inside the smokehouse during the processing of fat or fish with hot smoke.

The central cylinder must be equipped with a smoke divider

Another sign of a good smokehouse is the use of a pipe – a smoke flow divider. This is an ordinary stainless steel pipe, plugged on one side and perforated with a large number of holes. It is laid on the bottom of the middle section from the smoke generator to the chimney. Thanks to the divider, all products are smoked in the smokehouse with smoke of the same temperature.

You can make a vertical smokehouse with your own hands from a gas cylinder. According to their design, such devices are considered more advanced, since all the filling, including the smoke generator, are assembled inside one cylinder.

The vertical model is easier to build and has higher performance

The shape and design of such an apparatus turns out to be more concise; it makes sense to make such a hot-smoked smokehouse from a gas cylinder, if only because it takes up less space, is easier to operate and transport.

Options for the layout of devices for cold smoking

Devices for processing products with cold smoke are built, as a rule, from three cylinders. The smallest, at 10-25 liters, is used to generate smoke. The middle section is used as a cooler, and the last section, made from the largest cylinder, essentially functions as a smoke cabinet.

Scheme for cold smoking

In this case, the center section is not loaded, or in rare cases, a container of flavored water is placed.

There are also designs with a vertical arrangement of the cylinder, in which case the smoke is cooled to the required temperature by supplying cold air through an additional pipe.

In a homemade version, the cooling of the smoke can also be carried out using a water bath.

Apartment version of the smokehouse

Balloon selection and preparation

For the manufacture of the apparatus, gas containers of Soviet production are best suited, 50 liters and 27 liters each. The metal on the walls of such cylinders is thicker, and the quality of the welds is noticeably higher than that of modern models. A hot-smoked smokehouse from such a gas cylinder, photo, will turn out to be an order of magnitude more durable and reliable.

Before trying to take the first steps in the manufacture of a smokehouse, the cylinder must be washed and freed from the remnants of the gas condensate film on the inner walls. To do this, the valve is treated with brake fluid or kerosene, after which it is turned out with a special balloon wrench.

The next step is washing. Water is poured inside with a small amount of soap and the liquid is allowed to stand for at least a day. Then everything is drained, the procedure for washing the cylinder can be repeated with hot water.

In this way, containers or cylinders are evaporated from oil products in production before welding.

What to do if you can not remove the valve

In old cylinders, the tap sticks so much that it can only be turned off after burning out the investment lubricant and the cord on the thread. But it is absolutely impossible to do this until the container has been washed from the remnants of gas and condensate.

Therefore, it is necessary to drill holes in the bottom and upper wall of the cylinder, through which the container is washed.

How to make a smokehouse from a gas cylinder with your own hands

First of all, it is necessary to decide on the design of the smoking apparatus, to use the principle of cold or hot smoking. Not only the technology differs, but also the quality of the product, the period of its stay in the smokehouse. In addition, you will need to choose the type of apparatus, make it mobile or stop at the stationary version of the smokehouse. In the first case, it is desirable to restrict the minimum number of cylinders in order to reduce the size and weight of the structure. In the second case, restrictions are removed, the appearance and quality of the prepared product comes to the fore.

Do-it-yourself hot-smoked smokehouse from a cylinder

Apparatuses built on the principle of hot and cold smoking are not interchangeable. That is, in a hot smokehouse, with fine adjustment of the smoke generator, if desired, you can smoke with cold smoke, although the quality of the products will be mediocre. In a cold smokehouse, the cylinder arrangement system will not allow you to organize hot processing at the desired level of quality, no matter how hard you try. Therefore, most do-it-yourselfers prefer to build the hot version, even if at a higher cost.

Model Selection

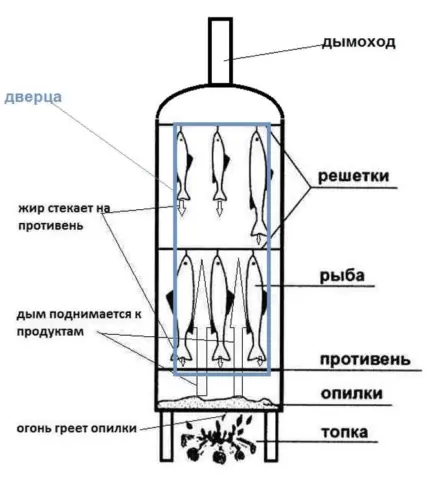

For the first experience, it is best to choose the simplest option, for example, to assemble a smokehouse from an oxygen cylinder with your own hands. The scheme of such an apparatus is presented below, nothing complicated. All that needs to be done is to cut out the door, weld on the sheds and install grills or hangers for fish and meat inside.

Scheme for an oxygen cylinder

Features of the smoker device:

- The smoke generator in the smokehouse is a pile of wood chips poured onto the bottom of the cylinder. Heating is carried out by an open flame through a thick metal bottom;

- To install the smokehouse to the cylinder, it will be necessary to weld metal supports from the reinforcement;

- Metal strips are welded onto the slots and into the base of the neck to prevent air from seeping into the smokehouse. Otherwise, the smoke may ignite.

Oxygen cylinders are hard to come by at a reasonable price, so hot-smoked enthusiasts make their own vertical smokehouses from propane gas tanks.

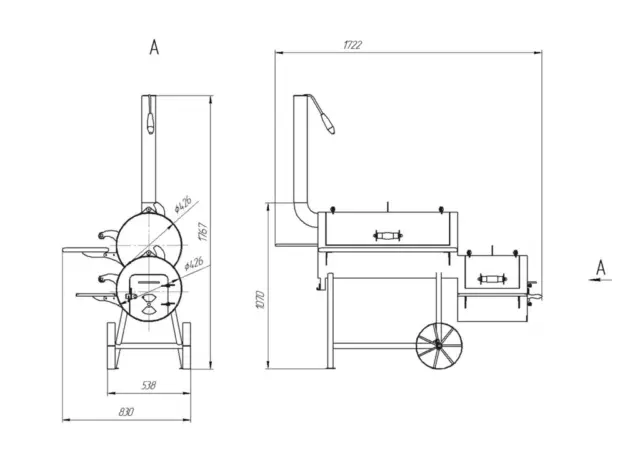

For stationary smokehouses, you can use the classic model with a horizontal arrangement of the main smoking section.

Dimensions and drawings

This design is considered more difficult to manufacture, since it is required to ensure high quality welds on the relatively thin metal of the propane tank. In addition, even from the drawings it can be seen that a hot-smoked smokehouse from a gas cylinder turns out to be too bulky and heavy.

Scheme of a hot smokehouse of the “steam locomotive” type

Therefore, horizontal hot-smoked apparatuses are more often made for the status of owners than for real smoking and preparing food for the winter. A detailed description of assembling a smokehouse with your own hands from a gas cylinder is shown in the video:

Preparation of tools and materials

Regardless of the chosen scheme, to build the device you will need:

- Welder, semi-automatic or inverter with automatic current adjustment function for thin metal;

- Bulgarian with a set of cutting discs;

- Electric drill with a set of drills and a nozzle with bronze bristles for removing rust and paint;

- Metal scissors.

In addition, it will be useful to have a variety of metalwork tools on hand, ranging from a coccygeal key, pliers, a set of files, clamps. In the course of assembly, you will have to use steel reinforcement, sheet metal, rods and pipe trimmings. In any garage, any do-it-yourselfer always has enough of such rubbish, so there will be no problems with materials.

Assembly algorithm, assemble the firebox

The vertical smokehouse is assembled from the lower compartment, or firebox, and the upper one, the smoke cabinet. First you need to make a firebox from a 27-liter propane cylinder. To do this, the floor of the body and one of the round walls are cut off from the tank, from which the lower bottom will be obtained. We weld the legs to it, in the remaining part we cut out the window under the door, the smoke outlet and the grate.

Firebox from a 27l cylinder

Additionally, you will need to install a grate and hang a door.

We assemble the upper cabinet of the smokehouse

For the smoking compartment, a standard 50 liter cylinder is used. We cut the door to almost the entire height of the container, inside we install grates for laying products.

The main problem is how to properly weld the two hulls

We align both bodies according to the level and plumb and weld along the contact line

Align the position of the door and weld the canopies

It remains only to weld the pipe, and the smokehouse from the gas cylinder is ready to go.

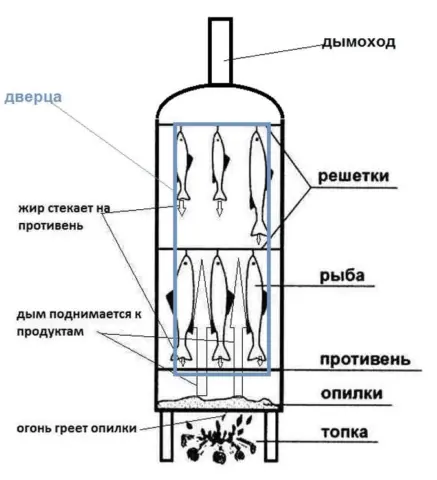

Cold smoked smoker from a gas cylinder

The operation of the cold smoking apparatus requires that the system must have a container or line in which the smoke would be cooled to the required temperature of 40ОC before it enters the food container.

Model Selection

If you plan to build a cold smoked smokehouse with an eye to selling, then you can use the model shown in the photo below.

For everyday use, you can choose a simpler model, for example, remove a vertical cabinet, smoke products in a horizontal cylinder, and organize gas cooling through an additional pipe.

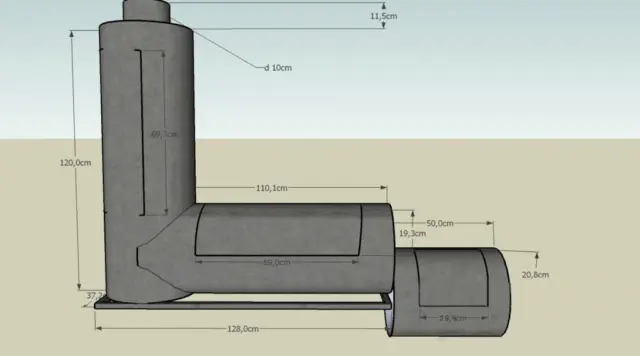

Dimensions and drawings

The design of the cold smoking system is shown in the diagram below.

In this case, a structure with a very high center of gravity is obtained, one wrong move, and the smokehouse can tip over, so you have to make very wide supports.

Preparation of tools and materials

If you build the device according to a simplified scheme, then you will need a minimum amount of materials:

- Cylinder for 50 l;

- Metal container for a smoke generator;

- Smokehouse supports;

- Sheds;

- Pipe cooler.

As the latter, you can use any steel or cast iron pipe with a diameter of at least 90 mm and a length of at least a meter. For work, we use a grinder, a welder, a drill with a set of drills.

Site selection and preparation

To assemble the structure, you do not need to look for a separate section. The smokehouse can be assembled and installed in close proximity to the house, since the smoke for cold smoking during the processing of products is practically not felt even near the device.

Assembly Algorithm

For a cold smoke smokehouse, almost any cylinder can be used, even with holes and traces of corrosion. But all the same, the container will need to be disassembled and be sure to rinse, pour several liters of water with soda into it and boil it over a fire. Otherwise, the smell of gasoline and gas cannot be removed.

First of all, you need to cut the door.

Then we mount the body on supports or a frame bent from reinforcement, fasten the cut sector on hinges to the cylinder. At the same time we weld the chimney pipe.

A smoke generator is best made from a metal box or a firebox from a wood-burning brick oven. The most difficult step in the entire smokehouse assembly process is the installation of the cooler pipe. The dimensions and length will have to be selected manually, adjusting by trimming from the ends with a cutting wheel.

If qualifications for this level of work are not enough, then you can replace the steel pipe with a conventional aluminum chimney, which was actively used in kitchen hoods a couple of years ago.

Do-it-yourself smokehouse from a freon cylinder

The dimensions of the metal container for storing freon are not as large as those of propane or oxygen cylinders, so only a small apparatus for preparing smoked meats in the field can be built from it.

First of all, we cut off the top cover of the container, remove everything that remains inside, we also cut off the extra parts on the surface with a grinder. We leave only the side handles.

Kit for making a smokehouse from a freon cylinder

Separately, you will need to pick up a small round pallet, which we will install inside with three bolts. Such a plate is needed to collect the accumulated fat.

Next, you need to make a grate for laying products. You can use any household wire racks and holders, it is better if they are nickel plated. We install the grate inside the cylinder on three bolts through the holes drilled in the walls just below the seam.

The lid can be taken from microwave dishes. After loading the products, we set the smokehouse on the coals and wait until the hot combustion products smoke the bookmark.

Finishing and painting

Most gas storage tanks are made of ferrous metal, so the smoker needs to be painted or blued. In any case, it is desirable to clean the body to white metal and thoroughly degrease it. Can be painted with epoxy paint with black filler.

Instead of paint, the body can be blued, for this a thin layer of machine oil is applied to the walls and heated to 200оC. Blueing will not peel off even with strong heating of the smokehouse.

operating rules

First of all, you need to think about how to attach the smokehouse to the site. The legs of the apparatus are best fixed with hooks or anchors. This solution prevents the cabinet from falling during loading and operation.

In addition, during the smoking process, large amounts of carbon monoxide can be released from the slots on the door and on the welded joints of the cylinders. To avoid poisoning, it is necessary to work with a smokehouse in a draft or in an open area, but not in a closed room.

Photo ideas of do-it-yourself cylinder smokehouses

The designs of smoking machines can be truly beautiful and original.

Conclusion

A well-planned and assembled do-it-yourself smokehouse from a gas cylinder will always be the subject of envy and respect from neighbors and acquaintances. The device will always be in the spotlight, it will be copied and actively interested in its work. So when choosing a model, design should also be given maximum attention.