Contents

Seedlings are grown in early spring, when daylight hours are still short. Artificial lighting solves the problem of lack of light, but not every lamp is equally useful. For plants, parameters such as intensity and spectrum are important. The best solution is to illuminate the seedlings with an LED strip, assembled with your own hands in a few minutes.

The benefits of artificial lighting

The lack of light adversely affects the development of seedlings. In plants, photosynthesis is inhibited, leaves and stems begin to fade. Vegetable growers solve the problem by installing artificial lighting from lamps. Yellow or white glow has a positive effect on the process of photosynthesis, but they do not bring other benefits. All the necessary spectrum contains sunlight, which promotes the development of cells, leaf plates, and the formation of inflorescences. The illumination of seedlings with LED strips of different luminescence allows you to get as close as possible to the indicator.

LEDs emit the spectrum that seedlings need, which is available in natural light. Scattered rays are better captured by plants. To obtain them, reflectors from mirrors or foil are installed. Of the entire emitted spectrum, three colors are especially useful for seedlings:

- blue – stimulates growth;

- red – accelerates the formation of inflorescences;

- pink – combines the useful functions of blue and red.

To get the full spectrum, they began to use ribbons to illuminate seedlings from LEDs of different luminescence.

In the video, the illumination of seedlings with LED strip:

Pros of using LED strips

LEDs have the main advantage – they emit the spectrum of light necessary for seedlings, but there are a number of important advantages:

- the tape consumes little electricity;

- LEDs emit light waves of different lengths, better absorbed by plants;

- the tape is designed for a long service life;

- low voltage operation makes the LED strip fire and electrical safe;

- LEDs have minimal flicker, no UV and IR radiation;

- LEDs are environmentally friendly due to the absence of harmful substances, such as mercury.

The disadvantage is the cost. The price of a good LED strip with a power supply is 7-10 times higher than a cheap LED light bulb, but the backlight will pay off in a couple of years.

Rules for mounting the backlight

The illumination for seedlings on the windowsill is equipped with an LED strip so as to minimize the ingress of moisture on the electrical part. Attach light sources above the plants. You can glue a glowing strip to the back side of the shelf of the top tier of the rack. Reflectors are placed on the sides of the box with seedlings. In this position, the mirror surface diffuses light better.

When growing a large number of seedlings, large racks with five shelves are made and placed on the floor. The remoteness of the structure from the window requires an increase in the illumination time. So that the LEDs do not overheat from prolonged operation, the tapes are glued to an aluminum profile.

If the backlight is fixed to the back side of the shelf of the upper tier of the rack, then the possibility of adjusting the height of the lighting is excluded. The light source should be located above the seedlings with a gap of 10 to 40 cm. LEDs practically do not emit heat. The danger of leaf burn is excluded, and this allows you to set the optimal gap – 10 cm.

When pecking sprouts, the lighting device should be brought as close as possible to the boxes. The seedling is growing rapidly, and with it, the light source needs to be raised to withstand the gap. For this reason, it is better not to tightly fasten the LED strip to the shelves of the rack, but to make a separate lamp from an aluminum profile or a wooden beam. A home-made lighting device is fixed with ropes to the jumpers of the rack and, if necessary, lowered or raised.

Choosing a backlight tape

Many vegetable growers are not afraid of the cost of the LED strip, but the lack of experience in choosing and connecting it. There is nothing difficult in this. Now we will look at how to choose an LED strip for lighting seedlings and what other details will be required.

All tapes are sold in lengths of 5 m, wound on a roll. It will have to be cut to the size of the rack shelves, and the pieces connected with wires. An alternative are aluminum rulers with soldered LEDs. The metal base serves as a cooler. Rulers are produced in different lengths and it is easier to choose them for the size of the rack, but the cost of the product is slightly more expensive than the tape.

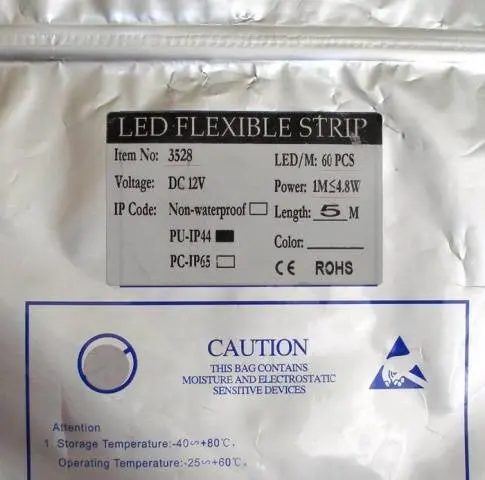

When buying an LED strip look at the following characteristics:

- Glow brightness. The LEDs are marked with a four-digit number. The higher the value, the brighter the ribbon emits light.

- Volume of light. A certain number of LEDs are soldered to 1 m of the base: 30, 60 or more pieces. As the number of bulbs increases, the LED strip emits more light.

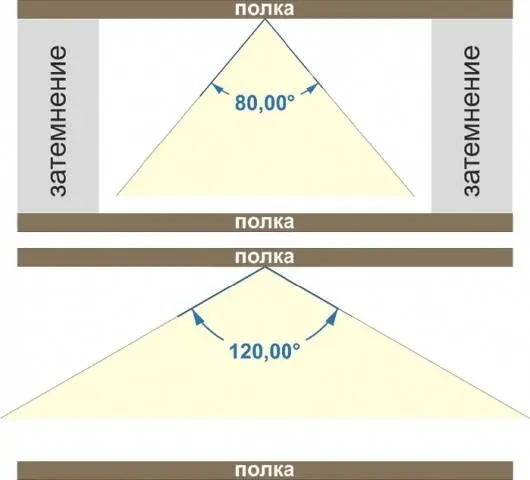

- LEDs differ in the angle of illumination. Light bulbs come with an indicator of 80 or 120о. When using one tape to illuminate a large area, it is better to choose a product with a glow angle of 120о.

- In order not to get confused in the four-digit designation of LEDs and their number, you can simply read the marking of the luminous flux value, indicated by Lumens (Lm), on the product packaging.

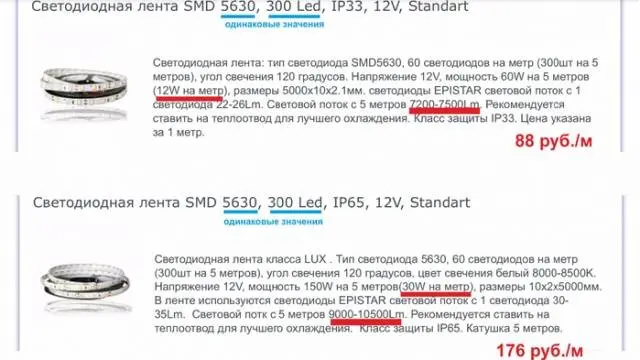

- The cost of a tape with the same number of LEDs and their number is different. As an example, the photo shows a comparison of two products, where LEDs with the number 5630 are used in the amount of 60 pieces / 1 m, but the power and volume of light are different.

It is optimal for seedling illumination to choose a product with LED number 5630, a power of 20 W / m and a glow angle of 120о.

An important indicator is the power of the LEDs. The larger the value, the more heating occurs. Aluminum profiles are sold for heat dissipation. When making a homemade backlight, you should not save on this element.

Ribbons are sold in different colors. For plants, it is optimal to use two colors: blue and red. If the seedlings are in a room, such lighting creates visual discomfort. The best solution to the problem would be the manufacture of a lamp with warm white LEDs.

LEDs run on 12 or 24 volt DC. The connection to the outlet is through the power supply. By power, the rectifier is selected with a margin. If you take it back to back, then the electronic device will quickly fail from overheating. For example, the power of 5 m of tape is 100 watts. A power supply rated at 120-150 watts is suitable. More is better than less.

Assembling the LED Light

To make a lamp, you will need a bar equal to the length of the shelf for seedlings. You can use a wooden beam, but it is better to buy an aluminum profile. It will be neater, plus the side walls will play the role of a cooler.

If white LEDs are selected for illumination, one luminous strip will suffice above the shelf with seedlings. With a combination of red and blue LEDs, a lamp is made of two strips. For pairing, aluminum profiles are screwed with screws to a wooden plank parallel to each other.

The LED strip is cut along the length of the profile. The place of cutting is easy to determine by the applied pattern in the form of scissors. Solder two wires to one end or put a connecting connector. On the reverse side of the LEDs there is an adhesive layer covered with a protective film. It must be removed and glued to the aluminum profile tape.

The lamp is ready. Now it remains to connect the LED strip to illuminate the seedlings to the power supply. The LEDs will glow if the polarity is correct: plus and minus. Phase and zero markings are on the power supply. There are “+” and “-” marks on the tape at the place where the wires are soldered. The wire coming from the minus is connected to the zero contact on the power supply, and the positive wire is connected to the phase contact. When connected correctly, after applying voltage, a home-made lamp will light up.

The video shows the manufacture of the lamp:

Fixtures are made in the same way as the number of shelves of racks. A homemade lighting device is hung on a rope above the seedlings. With the growth of plants, the lamp is raised higher, observing a gap of at least 10 cm.

Точна информация за подбора на лента ! Ще си направя сама, вече зная какво да търся! Благодаря !