Contents

PPU hives are slowly but surely spreading through domestic apiaries. Experienced beekeepers even try to make them themselves. However, this option is beneficial if the beekeeper intends to expand his business. Casting beehives from polyurethane foam requires a special matrix, and it is profitable to buy it only in mass production.

What are the qualities of polyurethane foam hives

Before you buy forms for PPU hives and start their mass production to expand your apiary, you need to know what qualities such a home for bees has. Experienced experts advise you to first buy a pair of polyurethane foam beehives for wooden houses, test them in action, get used to them.

The main positive quality of PPU hives is the preservation of heat, resistance to moisture. Polyurethane foam houses are warm, they do not require mandatory skidding for the winter in a shed. PPU in the rain will not change their parameters compared to wood. Polyurethane foam is not gnawed by mice, bees. The hives consist of compact, interchangeable polyurethane foam elements.

In summer, the inside of the polyurethane foam house remains cool. The design is increased or decreased due to removable sections. Lightweight beehives made of polyurethane foam are easy to carry and take out to the field. The mass of polyurethane foam three-hull house reaches 17 kg.

As for the negative qualities, they also exist. Despite quality control by SES services, polyurethane foam remains a chemical material. In the case of a fake or self-made with a violation of technology, the hive is able to emit odors that affect the bees and the taste of honey. PPU houses have a short service life. They are recommended to be replaced every 5 years. The damaged section of the polyurethane foam hive cannot be repaired, but it is easy to replace it with a new element. Polyurethane foam is afraid of fire, melts when exposed to high temperatures.

Convenient polyurethane beehive in terms of washing. The material does not absorb moisture. Sections of PPU hive are well washed with hot water with the addition of laundry soap.

How PPU affects the quality of honey

Polyurethane foam contains polyol and polyisocyanate. Individually, each substance is dangerous to humans. However, when interacting with each other, toxic substances are neutralized. The resulting polyurethane foam is completely safe. The material is used even in medicine. PPU has no negative effects on the life of bees and their products. In production, polyurethane hives undergo quality control, are checked by SES services.

In the event of a violation of technology or the acquisition of low-quality materials, the beekeeper risks spoiling the honey and even destroying the bee colonies.

Penoplex hives: disadvantages and advantages

In general terms, bee hives made of polyurethane foam, polystyrene foam and even polystyrene foam have the same pluses and minuses. Benefits include:

- Good thermal insulation. In winter, the inside of the hive is warm, and cool in summer.

- Reliable soundproofing. Bee colonies are protected from extraneous noise.

- Hive versatility. All parts of the house are interchangeable. A broken section is easy to replace with a new element of a similar model.

- Light weight. The hive can be lifted by one person.

- Ease of transportation. Hives are convenient for a nomadic apiary. During transportation, the sections are simply tightened with straps so that they are not scattered by the wind.

- Environmental Safety. Certified hives do not emit toxic odors. The houses are safe for bees, humans, bee products.

- Resilience to natural phenomena. Compared to wooden counterparts, new generation hives are not afraid of rain, frost, heat. They only need to be protected with paint from direct exposure to sunlight.

Summing up, it is worth noting that PPU hives have more advantages. Styrofoam and expanded polystyrene are gnawed by bees, mice, birds peck. Both materials are afraid of aggressive solvents. Polyurethane foam hives are more reliable and are gradually pushing competitors out of the market.

Of the shortcomings of modern hives, increased flammability is in the first place. Damaged sections cannot be repaired. They just need to be changed. The downside is the lack of airflow. If you do not provide effective ventilation, increased humidity will form inside the hive.

How to assemble beehives from polyurethane foam with your own hands

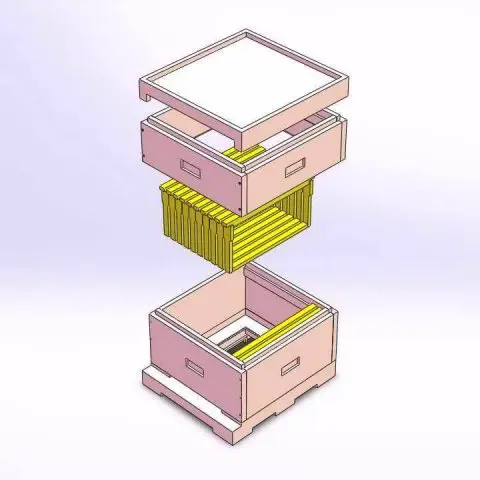

It is unprofitable to buy molds for casting beehives if you intend to assemble a couple of PPU houses. The easiest way is to use ready-made polyurethane foam blanks. The most popular beehive according to PPU reviews is the KomboPro-2018 model. The assembly process of the polyurethane foam structure consists of the following steps:

- With a sharp clerical knife, cut off the excess of hardened polyurethane foam protruding beyond the boundaries of the part.

- The ends of the connecting bars are painted over with water-based paint with the addition of green tint.

- A section of a polyurethane foam beehive is folded from the prepared parts on a flat surface. The blanks are tightened with self-tapping screws 60-70 mm long. First, PPU sheets are coupled with bars forming the frame of a polyurethane foam house.

- When the body of the polyurethane foam hive is completely pulled together on the bars, the joints of the polyurethane foam sheets are additionally fastened with self-tapping screws at the corners of the structure.

- A stapler with staples 14 mm long fixes a plastic corner that protects the edges of the PPU sheet from abrasion. Further frames with honeycombs are laid on the corner.

- Legs are arranged at the bottom of the polyurethane foam hive. Stands are cut from pieces of bars. Holes are drilled at the fixing points.

- The blanks are screwed with self-tapping screws to the frame of the polyurethane foam hive.

- At the end of the assembly of the polyurethane foam hive, a notch is installed. The bar is placed with the hole down, pressed with plastic corners, which are fixed with stapler staples 6 mm long.

- When transportation of the PPU hive is required, the bar with the notch is turned upside down. For reliability, it is fixed with a self-tapping screw 20 mm long.

According to reviews, polyurethane foam hives are easy to assemble. However, the folded PPU house is not yet ready to receive bees. It needs to be painted.

The process begins with grinding all the elements of the case. Particularly carefully sandpaper is passed along the joints of polyurethane foam and wooden slats. The very surface of the polyurethane foam boards must not be rubbed heavily, so as not to damage the surface durable layer of polyurethane foam.

At the end of grinding, the polyurethane foam beehive is painted. You can use a spray gun or a regular brush. The color of the paint for the polyurethane beehive is optimally chosen natural, for example, green. Paints are best used without smell. Acrylic-based compositions have proven themselves well. Rubber paint is considered the best for polyurethane foam hive. After hardening, it forms an elastic, durable film, resistant even to impacts.

Making hives from polyurethane foam using a mold for casting

To independently engage in the casting of polyurethane foam houses, you will need a mold for metal hives. She is expensive. It is unprofitable to buy a mold for casting several polyurethane foam houses. The hive form will pay for itself in a large apiary.

Sometimes craftsman beekeepers make molds for casting a polyurethane foam hive on their own. Usually they are made in the form of a tin trough. In such matrices, simple rectangular sheets of polyurethane foam are obtained, from which the hive bodies are then assembled. When making the mold yourself, you need to pay attention to the height of the sides. They are made over 8 mm. In a matrix with smaller sides, thin sheets of polyurethane foam will be obtained. They will not withstand the pressure from inside the polyurethane foam hive and will sag.

The process of using a hive mold consists of the following steps:

- Before filling with foam, the inner surface of the matrix is lubricated with a special compound that prevents the cured polyurethane foam from sticking to the metal.

- The form is not completely filled with polyurethane foam. During hardening, the foam will increase in volume.

- After pouring polyurethane foam, wait at least 30 minutes. During this time, the foam will have time to harden and the part can be removed from the mold. If the hardened polyurethane foam blank does not fall out, the matrix is lightly tapped with a hammer.

- The extracted polyurethane foam blank is subjected to grinding. The next step is degreasing and painting.

The form is cleaned of adhering foam residues, prepared for the next pouring of a new polyurethane foam part.

Keeping bees in polyurethane foam hives

For polyurethane foam hives, traditional beekeeping technology is acceptable. However, a number of nuances exist. Here are the advantages of a PPU hive highlighted by the famous Czech beekeeper Petr Havlicek:

- Heat is retained inside the polyurethane foam hive, an ideal microclimate is created. Intensive development of the nest begins in early spring.

- In each polyurethane foam house, at least 1 foundation body is rebuilt.

- Up to 5 kg of honey can be obtained from a multi-shell polyurethane foam system with 90 extensions per season.

- The simplicity of caring for a polyurethane foam hive lies in the absence of the need to reduce nests for the winter.

- In order to prevent swarming in the PPU hive, from about May 15, it is necessary to unite the separated families, creating new layers.

- To increase the quality of the performance of a polyurethane foam house, you can cover the inside and outside of the walls with aluminum foil.

The problem of polyurethane foam remains low hygroscopicity. It is important to maintain good air exchange to avoid the formation of excessive humidity.

Conclusion

Polyurethane foam hives are superior in their performance to analogues from expanded polystyrene and polystyrene. When compared with wooden houses, the opinions of beekeepers are divided. Some prefer natural material, others like modern technology.