Contents

It is far from always and not in all situations that traditional foundations can be used – tape and slab. In some situations, they become too expensive: their arrangement can take up to 40-50% of the cost of the entire building. This usually happens during construction in areas with a large freezing depth (below 2 meters) or on unstable, weakly bearing soils. In such cases, often the best way out is a pile-grillage foundation.

What is a pile-grillage foundation

Everyone probably imagines a pile foundation: it is a number of piles buried in the ground to the level of the bearing layer or below the freezing level. In its pure form, this type of foundation is rarely used. This is due to a peculiar design that does not allow redistributing the load from the house between the piles. Therefore, the pile foundation is mainly made for log cabins made of logs or timber, sometimes for frame buildings. These types of building materials, due to their characteristics, redistribute the load themselves. They are poorly compatible with houses made of other materials.

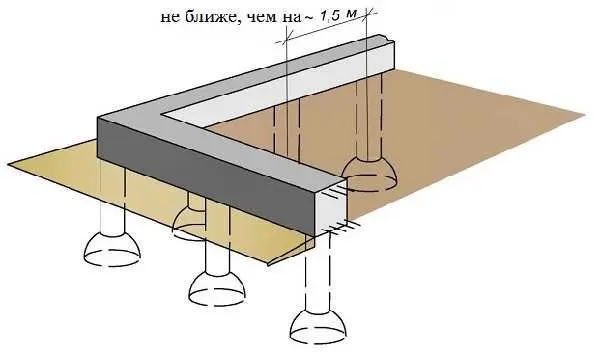

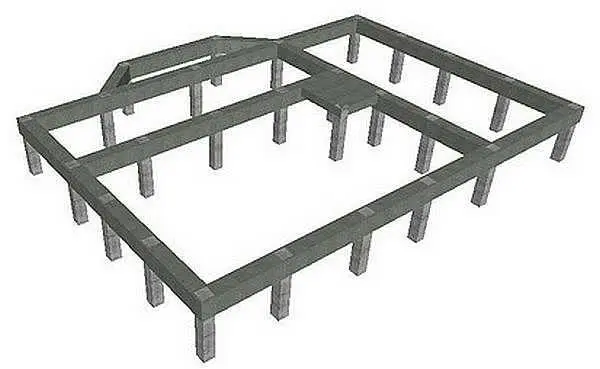

But their improved form – a pile foundation with a grillage – is devoid of many shortcomings and can be used for both brick and block buildings. In them, all the supports are tied with a metal or reinforced concrete (concrete) tape into a single structure. This tape is called grillage.

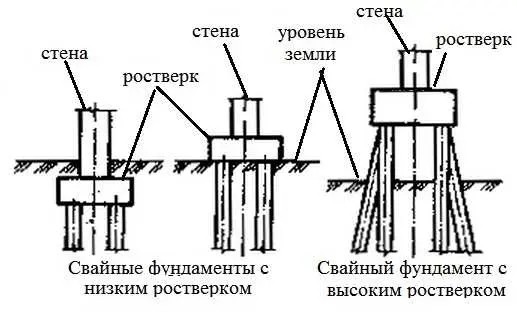

A grillage is a part of the foundation that unites the pile heads and serves as a support for the walls. It is the grillage that receives, and due to the closed structure, redistributes the load, transferring it to the piles. It can be metal, wood, concrete or reinforced concrete. According to the type of execution, concrete (reinforced concrete) grillages are low and high.

The high grillage is above ground level. Most often it is made of metal – large-section channels or square metal pipes. They also make such a grillage from concrete, but its device is more complicated: you have to figure out how to pour the tape at a distance from the ground.

How does a grillage work and what does it give

Any house in different parts will give a different load: decoration, furniture, sanitary ware, other things are placed unevenly. Consequently, the load from its different parts will be different. The grillage takes on these uneven loads and redistributes them. The “leveled” load is already transferred to the piles.

Why is it good? The fact that with the same pile load, there is less chance that they will shrink unevenly. And uneven shrinkage leads, as you know, to cracks in the foundation and walls. Therefore, the pile-grillage foundation is more stable. Although the main disadvantage of pile foundations remains: we cannot know what kind of soil is under each of the piles. Therefore, predicting their behavior is unrealistic. That is why architects do not like them very much: it is impossible to guarantee long-term operation of the house.

Strip foundation on piles

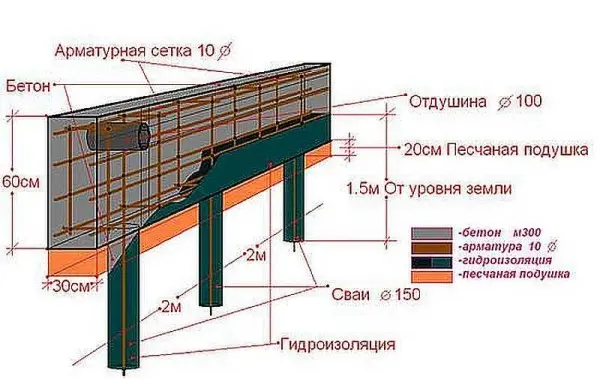

In this regard, low grillages are more predictable. They usually start below ground level and are cast from reinforced (or not – depends on the project) concrete. Moreover, the reinforcement of the piles is connected with the reinforcement of the grillage.

In this case, the grillage is a shallow strip foundation and it is made using the same technology. It differs in that it has a rigid connection with piles, which significantly increases the reliability and stability of the structure. Still such foundations are called tape on piles or pile-tape. This design is almost ideal: it combines the advantages of a pile and strip foundation, largely compensating for their shortcomings.

How does he work? The load from the house is transferred to the belt. Due to the presence of longitudinal reinforcement, it is redistributed over the entire area. Since the tape also rests on the ground, part of the load is transferred to it, the rest falls on the piles. At the same time, the load and shrinkage are uniform: the tape “levels” them.

You can read about monolithic strip foundations in this article.

In winter, when heaving forces begin to act on the foundation, all the advantages of a pile-strip foundation appear. If the house stands on heaving soils, their laying depth is below the freezing level, it is very difficult to imagine the conditions under which the house will warp or it will shrink unevenly.

When exposed to heaving forces on the tape, the “heels” of the piles, and they themselves, do not allow the soil to move the foundation. Therefore, strip-pile foundations are an excellent choice for highly heaving soils. In this case, the costs are much higher than in the construction of a conventional pile foundation, but much lower than in the construction of a strip below the freezing depth.

When can it be used

It is recommended to install pile-grillage foundations in the following cases:

- When unstable and weakly bearing soils go to a sufficiently large depth. These are karst, forest, peat soils, quicksand, vegetable and fertile soils of great thickness (more than 1,4-1,5 meters). In this case, the load must be transferred to the underlying dense soils with normal bearing capacity. It is not always possible to get to the bottom of them, and if it is possible, then the foundation turns out to be too expensive. Therefore, load transfer using piles is the best choice.

- In areas with large elevation changes. In this case, it is often much cheaper to use piles of different heights than to carry out ground leveling work or pour a deep tape that can compensate for the height difference.

One of the types of pile-grillage foundation – with TISE piles - With a high level of groundwater. Pile foundations are the only ones for which the level of groundwater does not matter. It is important that there is soil under the heel with a bearing capacity. The level of the location of the waters only affects the type of grillage: if the water is close to the surface, the grillage is made high, if it lies deep, you can make it low.

- When building in hard soils. In this case, small amounts of land work have a positive effect (compared to strip or slab foundations).

- If you decide to build a house using frame technology. Making a tape for it is a waste of money: you get too much margin of safety, which, in this case, is useless. In this case, a pile or pile-grillage foundation is the best choice.

- With a large mass of the building (more than 350 tons). Then it turns out that the tape or plate must be very massive, and, therefore, expensive. In this case, a pile-grillage foundation often turns out to be cheaper.

Sometimes it’s even simpler: they start from the lowest cost. But you should always remember that any type of pile foundation is less reliable than slab and strip foundations. And all because we cannot know exactly what kind of soil is under each of the piles. That is why, when calculating the parameters, an increased margin of safety is laid in the design. Not 1,2, as is commonly believed, but 1,4. And still, no one can guarantee anything.

Which piles to use

In pile-grillage foundations, any piles can be used. They are chosen based on the soil, the planned load of the house. Piles are made of metal, concrete, sometimes wood. They may be round or square. They differ in the way they are installed:

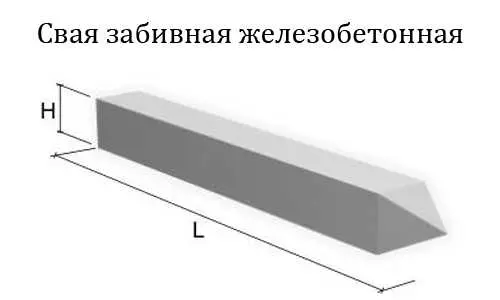

- Drop-in. They are installed without drilling or excavation. Usually they are clogged, that’s why they are called so. In private construction, they are rarely used: special equipment is required.

Driven reinforced concrete piles are used more often in the construction of multi-storey buildings - Bored. First, a well is made in the ground, then the formwork is installed and fixed in it. It contains reinforcement that increases strength characteristics. Then the whole structure is poured with concrete.

- Reinforced concrete drilling rigs. In this case, wells are also drilled, but ready-made reinforced concrete piles are installed (driven, but with less effort) in them.

- Screw. These are metal piles, pointed at the end and having helical blades that cut the ground. At great depths, special equipment is required, small ones, up to 2-3 meters long, can be installed manually.

One of the types of piles is screw. They can be used with grillages from different materials for different houses (to enlarge the image, right-click on it)

In private construction, bored piles are most often used. They are especially popular in the construction of cottages or baths. They can also be used in the construction of small houses. But if cottages and baths can be made without calculation, then when building a house it is very desirable to order a project.

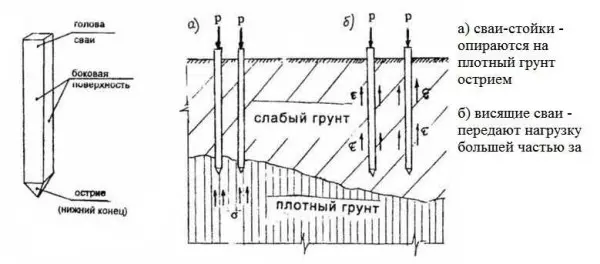

Different piles come in shapes: square or triangular, round filled and round hollow, sometimes complex shapes are developed specifically for the project. By the way piles transfer the load to the ground, they are:

- hanging;

- pile-racks.

What is the difference between piles by type of work (to increase the size of the picture, click on it with the right mouse button)

Hanging piles have a large lateral surface and a significant part of the load (up to 60-70%) is transferred with its help. They are used if the bearing capacity of the soil at the achieved level is not enough to withstand the entire load, and further deepening is impractical. In this case, the presence of a “heel” changes almost nothing: the main load is transferred by the surface, and not by the tip of the pile.

Piles-racks, on the contrary, most of the load is transmitted through the tip. In this case, the side walls are undeveloped and smooth, and it makes sense to expand at the end of the pile. One of the types of this type is TISE piles. They have a cylindrical expansion at the bottom, due to which they transfer the load over a large area. Also, the heel prevents heaving forces from lifting the foundation.

The location of the piles in the grillage

In most cases, supports in the ground are placed vertically. Sometimes you may need an inclined installation, and several pieces in one place. This method is used if horizontally directed forces can arise. For example, when building on sloping sites.

Piles can be located pointwise – under supports (columns, racks). This arrangement is typical in the construction of sheds or roofing over open areas. Then the supports are placed exactly under the columns holding the roof.

Under private houses of small number of storeys, piles are placed in the form of a tape. They are placed in one row, sometimes in two or three, shifting relative to each other. Sometimes in the most loaded parts, for example, in the corners, under areas with a large planned load, they are located in bushes: several pieces at a short distance from each other.

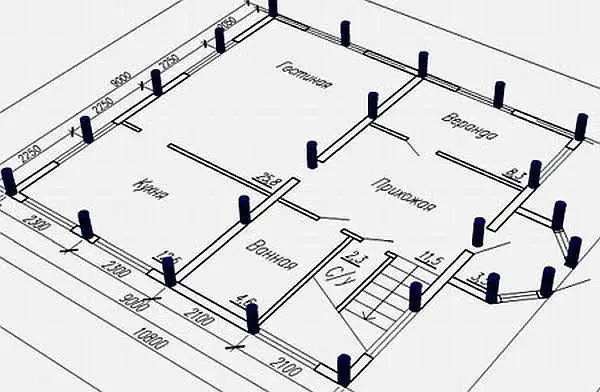

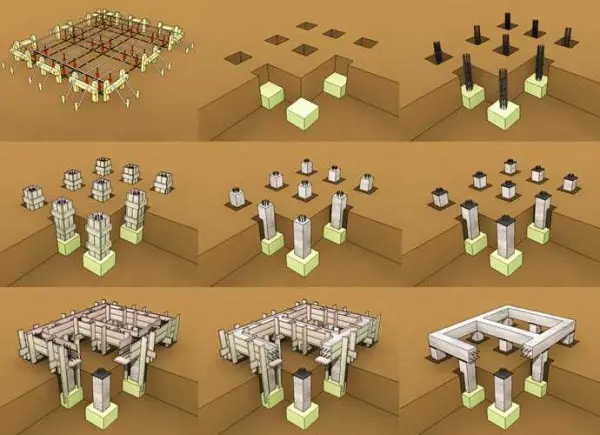

How to arrange houses on the plan yourself

When designing a pile foundation on their own, they usually do the following. On the plan of the building, drawn to scale, piles must be laid in the corners and at the intersections with the walls. If they are separated from each other at a distance of more than 3 meters, intermediate supports are placed between them. It is desirable that the piles are located one from the other at a distance of 2 to 3 meters.

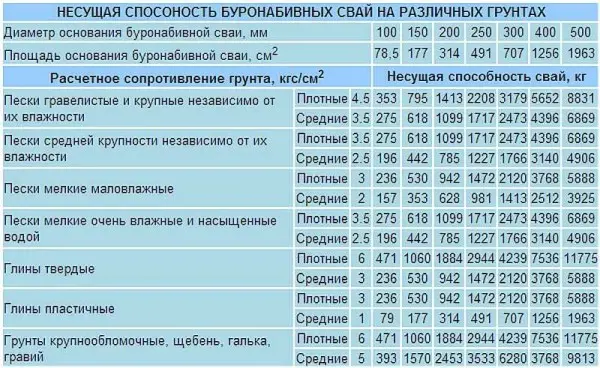

The principle is simple, but you still need to determine the required area of uXNUMXbuXNUMXbpiles. And it needs to be calculated (rather, picked up).

Calculation of the pile-grillage foundation

In order to be at least partially confident in the reliability of the foundation, it is desirable to at least approximately calculate it. To do this, you will need to do some not the most complex calculations.

- The mass of the house is calculated (all materials and the approximate weight of the “filling” are taken into account).

- Based on the weight and the safety factor, the required support area is determined.

- Since the piles have already been placed, we can count their number.

- Next, we select the cross-sectional area of the piles. Since we know their number, then multiplying by the selected area, we find out the total.

- The result obtained is compared with the reference area calculated earlier (point 4).

- If the area found in step 4 is larger than the one calculated in step 2, the selected pile parameters are suitable for us.

- If less, we increase the planned section of the piles, multiply again and compare. So we find the required pile area.

Sometimes it is more profitable not to increase the area of piles, but to put them more often. The calculation method does not change.

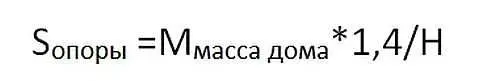

The area of support required for normal load distribution is calculated by the formula:

Where H is the bearing capacity of the soil (it can be taken from the table). The coefficient 1,4 is used because pile foundations require a larger margin of safety: we do not know what kind of soil is under all the piles. That’s why it’s better to be safe.

For more information about calculating the base area and calculating the mass of the house, see the video.

Construction technology

So, you have a project ready, or you yourself have decided on the location of the piles, their parameters, type and height of the grillage. You can start building.

Layout

First, the entire fertile layer of the earth is removed, it is taken out to the garden or stacked in one of the corners of the site. The foundation area is leveled. Then, using pegs and cords, mark the boundaries of the house. Moreover, two cords are pulled, marking the outer and inner surfaces of the walls. Be sure to check the geometry by measuring and comparing all the diagonals in pairs.

After the marking is completed, you can mark the places for installing piles. They are drawn on the plan and calculated, the distances between them are determined.

Earthworks and piling

How exactly the work will be carried out depends on the type of piles used. Most often, when building a house, screw or bored piles are used.

Screws can be screwed in by hand. When twisting, their heads are set at the same level. It is more convenient to mark it with cords.

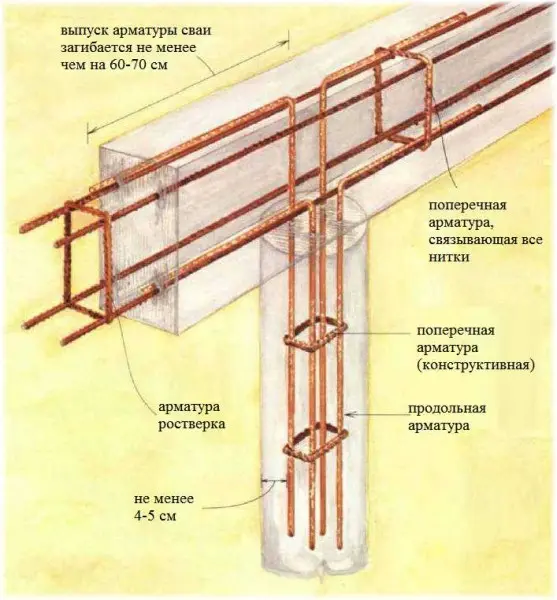

For bored ones, either special equipment or a hand drill of a suitable diameter will be required. Holes are drilled with these devices in the right places. The selected formwork is lowered into the finished wells, reinforcement is installed (four bars of ribbed reinforcement interconnected). If the foundation is pile-tape, then the reinforcement must have an outlet of at least 60-70 cm. It will then contact the grillage. The last step in this step is pouring the concrete.

Grill device

If a metal grillage is chosen, it is welded to the pile heads. When working, it is important to maintain strict horizontality: then the load will be transferred evenly.

For the installation of a recessed reinforced concrete grillage (low), it will be necessary to add rubble with a fraction of 20-60 mm and compact it with a vibrating platform. The minimum layer of crushed stone is 15 cm. In order to improve the bearing capacity of the soil under the belt, it is necessary to pour crushed stone in small layers (5 cm each) and carefully compact it with a vibrating platform. It will not be possible to compact well around the piles, but this is not so important.

Formwork is installed on this bedding. The width of the tape is slightly larger than the width of the walls, the height of the shields is made taking into account the required height of the base. The assembly of panels and the installation of stops exactly repeats the technology for installing formwork for strip foundations.

Reinforcement is carried out in most cases in the same way as during the construction of the tape: two belts at the top and bottom of ribbed reinforcement, transverse and vertical posts made of a smooth bar of a smaller diameter. All reinforcement rules are preserved. Only ligation with piles is added. The outlets of the reinforcement from the piles are bent: one row is tied to the lower chord, the second to the upper one (do not forget to make the outlets of different lengths). They must be at least 50 bar diameters (if reinforcement is used 12 mm, you need to bend 600 mm (50 * 12 mm)). The reinforcement scheme of the pile adjoining is shown in the figure.

How to reinforce the strip foundation, read here.

Installation of embedded parts

At this stage, it is necessary to leave ventilation ducts and lay pipes and ducts through which engineering communications (water supply, heating, electricity, sewerage) will be supplied.

If this is not done, then the concrete will have to be hammered. And this is a great evil for the foundation, because the integrity of the monolith is violated. So think over everything well: it will not be possible to redo it.

Read more about the choice of concrete for the foundation here.

Pouring concrete

Concrete is not just poured. It still vibrates. Without this process, it is very difficult to achieve uniformity and high strength. Therefore, the processing of foundation concrete with a vibrator can be considered an obligatory process.

If the air temperature after pouring the concrete is around +20°C, then the formwork can be removed after four days. During this time, the concrete will gain approximately 50% of the design strength, which is enough for the following work. If the temperature was around + 10 °, you will have to wait 10-14 days. At lower temperatures, conditions are considered wintery and poured concrete requires insulation or heating.

For all their attractiveness, pile foundations have disadvantages:

- As already mentioned, due to the fact that it is impossible to determine what kind of soil is under each of the piles, its behavior is almost impossible to predict.

- In such buildings it is impossible to equip cellars.

- With high grillages, it is necessary to somehow close the gap: animals and insects like to settle there.