Contents

- Options for stairs for the cellar, and what to consider when choosing their design

- Choosing the type of stairs to descend into the cellar

- What you need to know when calculating the basement stairs?

- What you need to make a metal staircase

- The procedure for the manufacture of stairs using a corner and a channel

- Ladder made of pipes

A cellar in a private courtyard is located under one of the buildings or installed on the site as a separate structure. For descent indoors, a staircase or steps are equipped. Most often they are made of wood due to the availability of the material, and the ease of its processing. But even if the cellar is located in the basement of the house, dampness is constantly present inside, mercilessly destroying wooden structures. Under these conditions, a metal staircase to the cellar is more reliable, which, although subject to corrosion, will last much longer than its wooden counterpart.

Options for stairs for the cellar, and what to consider when choosing their design

In general, for a cellar or basement, there are three types of stairs that differ in the material of manufacture:

- Wooden construction very convenient in terms of production. However, this natural material is afraid of dampness. You can slightly extend the life of wood if you take oak or other hardwoods for making the descent. Additionally, the blanks are impregnated with an antiseptic solution, after which they are painted. All these measures are good, but only for a short time.

- concrete descent with steps is an ideal structure for a cellar, but is rarely used in the private sector. If the cellar is located under the house, then it is advisable to build such a descent during the construction of the building itself. Concrete stairs require a lot of labor and precise design.

- The golden mean between these two structures is metal staircase, which, if you have a welding machine, is easy to make yourself. Steel is less susceptible to moisture than wood. A metal staircase only needs to be periodically tinted, but even without this, it will serve the owner for many years. Only without staining the metal will rust.

It is still necessary to choose the material for the manufacture of stairs, taking into account the location of the manhole in the cellar. In a separate basement, of course, the entrance will be located from the street. In spring and autumn, wet mud will stretch behind the sole of the shoe, and in winter – snow. This means that for an outdoor cellar, a ladder is needed only from a durable material, such as metal.

When making a descent into the cellar with your own hands, you need to take into account several important nuances:

- The shape and dimensions of the structure depend on the area of uXNUMXbuXNUMXbthe basement. For example, for a small cellar under the garage, the only way out of the situation may be a small ladder.

- The more often the basement is used, the more convenient the staircase should be. If the dimensions of the room allow, then it is desirable to organize a descent more gentle and with handrails.

- A person will lower conservation into the cellar, harvested crops from the garden, etc. And this is an additional load on the stairs. Metal is a strong material, but if you take blanks of thin section, the structure will sag under the load.

- In addition to the strength of the stairs, it is necessary to take into account its width and slope. The crop harvested from the garden is taken to the cellar in buckets, and even boxes. The descent should be convenient for a walking person with a bulky load.

If the basement is located under the house, then the entrance to it will be from the premises. For aesthetics, you can try to make a neater staircase that does not spoil the entire interior. Even at the design stage, they think over the configuration, dimensions and method of fastening the structure for descent.

Choosing the type of stairs to descend into the cellar

To descend into the cellar or basement, ladders and ladders are used. Choosing the right design depends on several factors:

- the dimensions of the basement, and for what purposes it will be used;

- how much money are you willing to spend on the manufacture of the descent;

- frequency of use.

Let’s look at a simple example. Let’s say you use the cellar often, but there is no money and time to make a flight of stairs. And the room is so small that there is nowhere to place the structure. In this case, preference should be given to an attached metal ladder. If there is money, time and desire, there is enough space, and you will use the cellar often, then here you can already stop at a marching structure.

When choosing mid-flight structures for construction, one must take into account the complexity of their manufacture. It will require the development of accurate drawings and the correct selection of material. After all, improperly selected thin blanks will bend over time under the influence of gravity, and the staircase will take on an ugly shape.

Attached type of stairs

Ordinary ladders are most often used in summer cottages. With the help of this simple design, they organize a descent into the cellar located under the building. Such cellars are often characterized by an entrance through a small hatch on the floor. You can go down here only along the attached stairs at a steep angle. The inconvenience of the design is still a narrow step on which you can’t stand for a long time.

However, even such a primitive descent can be arranged according to a different principle. If the basement allows you to make a larger slope of the ladder, and the hatch is not so small, the structure is installed permanently. For comfort and reliability, railings are welded from the pipe. And the steps themselves can be expanded. For a very small cellar, a removable ladder is welded. Usually such a design is narrow, and made of a thin profile. It is irrational to use thick metal for a removable ladder, as you will often have to wear it on yourself.

The bottom of the structure is equipped with rubber heels or steel pins that prevent slipping on the floor. Two hooks are welded on top of the stairs for fastening, so that during the movement of a person the structure does not tip over backwards.

The steps in the ladder are welded in steps of 34 cm, but no more. It is bad to rearrange the legs over a large span, especially if a person is walking with a load. On small spans, the step becomes more frequent, as a result of which fatigue increases. It is good if the steps are made of corrugated metal, which does not allow the foot to slip. You can even bolt on rubber pads.

For a stationary ladder, metal can be taken thicker. A channel and a corner are usually used. Handrails are welded from a pipe with a diameter of 25 mm. The bottom of the descent can be concreted into the floor. In another case, sheet steel heels are welded to the channel, and then fixed with anchor bolts to the concrete floor of the cellar. The top of the attached stationary ladder is screwed with anchors to the frame of the hatch or the top of the basement wall.

Marching type of stairs

If the construction of the cellar is still at the stage of project development, then just this time should be used to calculate the flight stairs. There are many design options, and at the same time the entrance to the basement will be developed for a specific model.

Marching descents are more difficult to make, but they have an undeniable advantage over attached structures:

- a gentle slope ensures comfortable movement of a person even with a load;

- the design allows you to make an increased width of the step, very comfortable for the foot;

- a small step determines the comfort of walking.

Handrails are made on the marching descent. Sometimes they are installed on both sides of the stairs. Then they still play the role of a fence that does not allow an elderly person or children to fall off.

When designing a marching staircase to the cellar from metal, you can take care of its beauty. Beautiful and safe steps are made of perforated stainless steel. The end of the handrails can be rounded so that they do not stick out with a piece of cut pipe.

If the entrance hatch of the cellar is narrow, and you don’t want to make a ladder, then you can weld a screw model from metal. The only drawback of the design is the inconvenient movement of the stairs with a load. Spiral staircases are difficult to manufacture, so they are rarely used for cellars.

What you need to know when calculating the basement stairs?

To make it comfortable to walk on the stairs, it must be properly designed. Let’s look at a few nuances that are worth paying attention to:

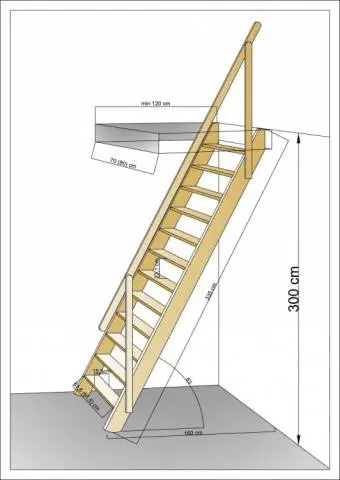

- The ladder is placed at a steep angle from 22 to 45о. Marching descents are gentle with a slope of less than 45о. The width of the steps is selected according to the size of the free space in the cellar. Although steps with a width of 700–900 mm are considered the standard. The distance from the steps to the ceiling should be at least 2 m. Then, when walking, a person will not have to bend down.

- The number of steps is calculated according to the length of the stairs. To do this, its length is divided by the height of the step, which is in the range of 150-180 mm. One march must contain a maximum of 18 steps. Otherwise, it makes sense to build a structure from several marches. The width of the step is about 300 mm.

- For deep cellars, structures are made of two or three marches with a turn of 90 or 180о.

- The railing is placed at a height of 800–900 mm from each step. For their fastening, vertical racks are installed with a pitch of 150 mm.

The metal descent is placed on a monolithic concrete floor or reinforced concrete slab. A heavy structure cannot be rested on a soft base. Otherwise, it will just load.

What you need to make a metal staircase

It should be noted right away that for the manufacture of a metal staircase you will need a welding machine and a grinder. You can’t do without these tools. A channel is best suited for the base, but a profile pipe can be used. The frame of the steps of the marching structure is more convenient to cook from a metal corner. A profiled pipe of a smaller section is also suitable. The steps themselves are sheathed with sheet metal with a thickness of 1 mm. If desired, steps from an oak board can be fixed to the frame from the corner.

Handrails and racks for them are made of a round tube with a diameter of 25 mm. Although thinner blanks, for example, 20 mm, can be used on racks. To make roundings at the ends of the handrails, the pipe will have to be bent in production. If this is not possible, then the rounding can be welded from magazine elbows of the same diameter. Only then should the welding joints be carefully sanded to avoid injury to the hand.

The procedure for the manufacture of stairs using a corner and a channel

So, for the base of the marching structure, two channels are being prepared. Their estimated length should be enough from the cellar floor, taking into account the concreting of the lower end to the edge of the entrance hatch. The frame of the steps is welded from a corner with a section of 50 mm. Sheet metal 1 mm thick was taken for sheathing.

Before you start cutting blanks, you must once again carefully review the drawings. Short elements can be welded in pieces, but the general appearance of the structure will be spoiled. In the case of channels, pieces cannot be welded. A bad weld under load can crack, so only a solid channel should be taken for the base.

The next step is markup. The channel and the corner are marked according to the dimensions in the diagram. Cutting blanks is performed by a grinder. In this case, all cut points must be ground with a cleaning wheel from burrs.

When all the elements are ready, two channels are laid parallel to each other, after which markings are applied under each step. If the dimensions of the cellar allow you to weld the steps on the ground, then the finished metal structure will only have to be installed in its place. But most often the size of the cellar is limited, and even two people cannot lift such a weight.

The easiest way is to immediately install the base of the channels in its place. Then it remains only to weld each step onto the frame in turn. In this situation, each person is looking for the easiest way for himself to solve the problem.

The finished metal structure in the cellar must be concreted. Here, a pit about 200 mm deep should already be prepared in advance. It is good if a piece of reinforced concrete slab is laid on its bottom to securely rest the stairs. Now it remains to fill the lower part of the structure with concrete with crushed stone in this pit. The top of the ladder is fixed with anchors to the wall. The structure will turn out to be heavy, so it is better to install two supports from a pipe or channel near the same wall, supporting the upper part of the stairs. At the end, the steps are sheathed with sheet steel, the welding seams are cleaned with a grinder and the metal structure is painted.

Ladder made of pipes

A ladder made of pipes is usually made 2,2 m long and 70 cm wide. Two pipes with a diameter of 50 mm are taken for racks. The crossbars will be located in increments of 25 cm. Blanks for them 70 cm long are cut from a pipe with a diameter of 25 mm. The first crossbar is welded, stepping back from the top of the racks 25 cm. Next, observe the established step.

The lower part of the racks is cut obliquely with a grinder. The resulting points will not allow the stairs to ride on the floor. From above, two hooks for fastening are welded to the racks, but you can do without them.

The video shows a homemade ladder:

When making stairs to the cellar, you need to think about your safety. So, you should not save on materials and neglect the correct calculations.