Contents

A kayak is one type of boat. It is perfect for fishing conditions and not only. It can really be used for hiking and just for walking along rivers or lakes. This is due to the fact that in comparison with other analogues, this boat has a number of advantages.

A kayak is not that difficult to make yourself, so there is no need to buy one, although this option can also be considered. The information in this article is aimed at somehow helping those who decide to make a kayak with their own hands.

The need for a kayak for a fisherman

Fishermen need boats to move around the reservoirs in search of promising places, as well as to catch fish from these boats. The presence of a boat makes the fishing process more dynamic and productive. This is due to the fact that the fishing area is expanding and the most inaccessible parts of the reservoir are becoming available. Kayaks are much more popular among anglers than other types of similar watercraft due to their better technical characteristics.

This is due to a number of advantages that it makes sense to talk about. For example:

- They are easy to use, which is associated with the safety of both being in the boat and when moving inside it.

- Boat stability plays a very important role, especially when you need to pull a large specimen out of the water or leave the boat by moving into the water. At any time, you can just as easily climb into the boat from the water.

- There is no need to bail out water from it, since it will flow out of the boat itself through holes that are located above the bottom level.

- A properly made structure will never sink, even if it capsizes for some reason, thanks to the presence of special partitions.

- The kayak is easy to transport to any distance, because it does not affect the aerodynamic properties of the car.

- This craft does not require special storage conditions. It is enough to hang it as high as possible in the garage or other room.

Which is better: buy a kayak or make your own?

If funds allow, then it is better to buy it. Unfortunately, not all anglers are able to do this due to lack of funds. Many of them embark on independent production purely out of interest. In addition to the fact that the boat will cost less, it’s amusing, and there is a sense of pride in their work. And although it will take a lot of money and time, it is still a very real and feasible task. Self-manufacturing is always associated with a number of advantages. In addition to being very interesting and instructive, you can always count on getting a quality product that meets the requirements that are stated. The task is greatly simplified by the fact that it is not difficult to find the right scheme, the necessary material, and also to acquire the necessary tools.

Homemade transparent kayak from branches and film Homemade stretch wrap kayak

DIY fishing kayak

What do you need to have?

First of all, you should decide on the availability of tools and materials. For such work, you need to have the following tools and materials:

- Electric jigsaw.

- Belt type electric grinder.

- Electric drill and electric screwdriver.

- Building hair dryer.

- Scissors of various sizes with a good sharpening of the cutting edge.

- Construction knife with a sharp blade.

- Pliers and nippers.

- About 4 sheets of plywood, at least 4 mm thick, of the appropriate quality.

- Fiberglass, sizes up to 20 square meters.

- Waterproof varnish – up to 1,5 liters.

- Aerosil A300 – about 120 grams. It must be added to the epoxy resin a day before its use.

- Epoxy resin – up to 10 kg.

- Spatula flexible rubber, for working with epoxy resin.

- Durable connecting wire.

- Disposable plastic cups.

- Brushes of various sizes – up to 5 pieces.

- Solvent up to 0,5 liters.

- Epoxy hardener – up to 5 kg.

- Disposable rubber gloves.

- Several pieces of wooden sticks, similar to those used for ice cream.

- Cargo.

- Masking tape.

- Working drawings that are necessary for the construction of the boat. They can be found on the Internet and downloaded, and then redrawn at a scale of 1: 1, which greatly simplifies the construction process. It will be enough to transfer the drawing to plywood and cut the blanks with an electric jigsaw.

Procurement of materials

The main materials are plywood, epoxy resin and fiberglass. When purchasing, you should pay attention to their quality. The features of these materials are indicated below in the text.

Plywood

To make a kayak, you need plywood, which has the appropriate dimensions (2240x1120mm) and is not sold in our stores. Therefore, you will have to turn to the Internet for help and place an appropriate order through it, although this does not give any guarantees.

Even through the Internet, such sheets are difficult to acquire, since not all organizations carry out such trade. This is due to the fact that plywood of this size is not in high demand due to transportation problems.

Despite this, there are companies that sell these types of goods over the Internet.

An example is the Penrus company. For the manufacture of a kayak, 2 types of plywood are suitable. For example:

- “Lauro Vermelho”, which is produced in Brazil. It is considered a very high quality material, on which you will practically not find defects or knots. Plywood is particularly durable, and its thickness is almost the same over the entire plane.

- “Amesklao”, which is an analogue of the Chinese manufacturer. The price of plywood is somewhat lower, but the quality is somewhat worse.

At the same time, it does not matter what color the plywood has, since this will not affect the construction process. After the construction is completed, the kayak can be painted in any, the most attractive color. For the manufacture of the boat, the color “Zhotoba” is suitable.

fiberglass

A little kayak or determining the type of fiberglass by smell

The quality of this material also plays a significant role in the process of self-manufacturing such a craft. When choosing a material, the main criteria are:

- The manufacturing process requires the use of fiberglass with a specific gravity of about 130 grams per square meter.

- Much more common material with a specific gravity of 100 or 200 grams per square meter. In this case, you should opt for a material with a specific gravity of 200 grams per square meter. As a result, it is really possible to get a high-quality and durable product.

- To obtain a high-quality end result, you should take those pieces of fabric that do not have bends, as they will interfere with obtaining a smooth surface. Fabric with cross traces of bends will bring many problems in the process of opening it with epoxy.

Epoxy resin

As stated above, about 10 kg of epoxy will be required, although many instructions indicate less material consumption. In this case, it is better to rely on the results obtained in a practical way, and they indicate that the consumption will be about 10 kilograms. If it remains, then not so much, and if not enough, then this may affect the quality of the product, since the epoxy resin hardens quickly enough. It is better if the entire surface of the boat is covered in one go, without stopping the process of applying the epoxy.

For work, the Etal-370 epoxy is suitable, for which the Etal-47F5 hardener is suitable. If we evaluate the ratio of price to quality and its main technical data, then this is the most suitable technical product.

Construction Stages

First you need to start preparing the workplace, materials and tools. Given the size of the boat, a car garage is suitable for its construction. In any case, there should be enough space, and working with epoxy resin requires special conditions.

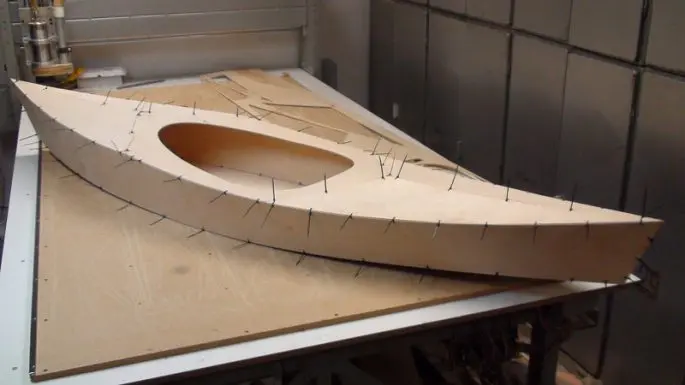

The construction of such a watercraft consists of the following technological stages:

- Based on the available drawings, they are engaged in the manufacture of all components. For this, an electric jigsaw and other tools are used.

- The assembly of individual parts of the parts is carried out, for which a masking tape is used.

- First of all, the decks and the lower part of the future kayak are assembled.

- After both parts of the product are ready, they are put together and evaluated how they fit one another.

- A layer of epoxy resin is applied to the inner surfaces of both parts.

- An unsinkability compartment is formed at the bottom of the boat, which consists of several partitions. They should also be treated with epoxy.

- After that, the deck and the lower part of the structure are adjusted again. As a result, they should ideally match each other.

- If everything is fine, then both parts are glued together and the joints are treated with epoxy. After that, the entire surface of the boat is opened with a layer of epoxy.

- At this stage, hatches are formed.

- The final stage is gluing fiberglass to the entire surface of the craft. At the same time, it is necessary to monitor the quality of fiberglass gluing. After the epoxy hardens, it is advisable to sand the building, and then paint it in any color.

Test

As a result of the construction, a relatively light watercraft should be obtained, which is easily transported to the reservoir using a passenger car. Here, on the pond, you need to start sea trials, built with your own hands, a unique boat.

The task of the upcoming tests is to check the technical characteristics according to the following criteria:

- Easy to manage.

- Movement speed, both unloaded and loaded.

- The maximum load capacity of the kayak.

As far as we know, the finished product should easily carry a load of 120 kilograms, without compromising fit and handling. The main thing is that the boat does not let water through anywhere. As practice shows, products created using this technology are easily repaired and have high strength, despite their lightness.

Do-it-yourself kayak from film, tape and plastic pipes – Homemade stretch wrap kayak