The roof made of bituminous soft tiles is easy to use, durable and aesthetic. Its big plus is that self-assembly is quite possible. The technology is not the most complicated, the weight of the fragment is small, it is attached to the adhesive base, additionally fixed with roofing nails. So the installation of soft tiles with your own hands can be done even alone.

Roofing cake for soft tiles

The attic under the roof can be warm or cold, depending on this, the composition of the roofing cake changes. But its part from the rafters and above always remains unchanged:

- waterproofing is stuffed on the rafters;

- on it – bars with a thickness of at least 30 mm;

- solid flooring.

Here we will consider these materials in more detail – from what and how to make, what features each of them has.

Water proofing

Waterproofing membranes are available in one, two or three layers. Single-layer membranes – the simplest and cheapest, perform only a dual task – do not allow moisture to pass towards the room and release vapors to the outside. In such a simple way, not only is the attic or attic protected from the penetration of condensate or suddenly leaked precipitation, but also excess moisture that accompanies human life is removed from the air. Single-layer membranes are poorly represented on the market. Practically they are produced by one company – Tyvek.

Two and three-layer membranes are more durable. They, in addition to the waterproofing layer, also have a layer that gives greater tensile strength. The third layer, if any, is the absorbent layer. That is, even if a drop of condensate has formed on the surface of the membrane, this layer absorbs it into itself, preventing it from spilling onto other materials. With sufficient ventilation, moisture from this layer gradually evaporates and is carried away by air currents.

Three-layer membranes (for example, EUROTOP N35, RANKKA, YUTAKON) are desirable if your attic is insulated and mineral wool is used as a heater. It is afraid of getting wet and with an increase in humidity by 10% loses half of its thermal insulation properties.

If there is a cold attic under the soft tiles, it is advisable to use a two-layer waterproofing membrane. In terms of strength, it is much better than single-layer ones, and at a price it is only a little more expensive.

Rims

On top of the waterproofing film, parallel to the overhang, the lathing strips are stuffed. They are necessary to create a ventilation gap. It will help maintain the normal humidity of roofing materials.

The crate is made of coniferous boards (mainly pine). The thickness of the boards is at least 30 mm. This is the minimum gap that will ensure the normal movement of air in the under-roof space. Before laying, the wood must be treated with an impregnation that protects against pests and fungi; after drying this layer, it is also treated with flame retardants, which reduce the combustibility of wood.

The minimum length of the board for the crate is at least two spans of rafters. They are attached and connected above the rafter legs. You can’t connect them anywhere else.

Flooring

The flooring under soft tiles is made solid. Materials are selected based on the fact that nails must be driven into it, therefore they are usually used:

- CAP 3;

- moisture resistant plywood;

- tongue-and-groove or edged board of the same thickness (25 mm) with a moisture content of not more than 20%.

When laying flooring under soft tiles, it is necessary to leave gaps between the elements to compensate for thermal expansion. When using plywood or OSB, the gap is 3 mm, between edged boards 1-5 mm. Sheet material is fastened with a run-out of seams, that is, so that the joints are not continuous. Fasten the OSB with self-tapping screws or ruffed nails.

Using boards as flooring, it is necessary to ensure that the annual rings of the wood are directed downwards. With the reverse arrangement, they will be arched, soft tiles will be lifted, the tightness of the coating may be broken. There is another trick that will keep the wooden flooring even if the moisture content of the boards is above 20%. When laying the ends of the boards, they are additionally fastened with two nails or self-tapping screws hammered close to the edge. This additional fastener will prevent the boards from bending during shrinkage.

The choice of the thickness of the material for flooring under soft tiles depends on the pitch of the crate. The larger the pitch, the thicker the flooring required. The best option is a frequent step and thin plates. In this case, a light but rigid base is obtained.

Another point concerns the installation of flooring for soft tiles around the chimney pipe. With a brick pipe, the width of which is more than 50 cm, a groove is made behind it (pictured). This design, reminiscent of a mini-roof. It separates the rain streams, they roll down the sides of the pipe without flowing into the under-roof space.

After installing the flooring, its geometry is checked. The length is measured, the width of the slope at the top and bottom, the height of the slope on both sides, the diagonals are measured. And the last check – tracking the plane – the entire slope must lie entirely in the same plane.

The device of a roof from the built-up materials is described here.

Soft tile roofing technology

When buying, you will most likely be provided with instructions, to which the installation of soft tiles will be described step by step and in detail, indicating all the exact dimensions that this particular manufacturer requires. These recommendations should be followed. However, it is worth getting acquainted with the order of work and their volumes ahead of time – in order to understand the intricacies of installation and the required amount of materials.

We must say right away that it is necessary to handle soft tiles when laying carefully – she does not like it if she is bent. Therefore, try not to bend or crush the shingles unnecessarily (this is one fragment consisting of a visible and mounting part).

Overhang reinforcement

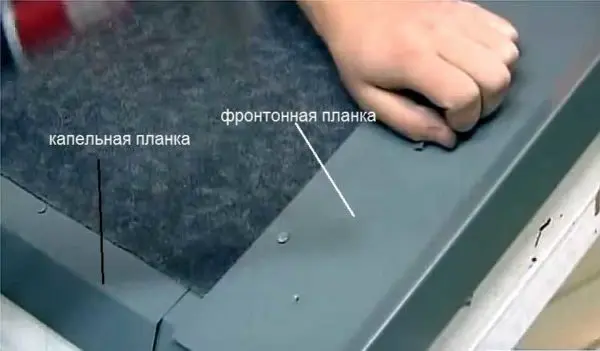

The drip bar is installed first. This is an L-shaped sheet of metal coated with paint or polymer composition. Polymer coating is more expensive, but also more reliable. The color is selected close to the color of bituminous tiles.

The task of the drip bar is to protect the crate, sections of rafters and flooring from moisture. With one edge, the dropper is laid on the flooring, with the second it closes the overhang. It is fastened with galvanized (stainless steel) nails, which are hammered in a checkerboard pattern (one is closer to the fold, the second is almost at the edge). Fastener installation step – 20-25 cm.

The drip bar is sold in two-meter pieces. Having laid the first element, the second is fixed with an overlap of at least 3 cm. If desired, the gap can be closed: grease the joint with bituminous mastic, fill it with sealant. At the same stage, a spillway system is mounted, in any case, hooks are nailed that will hold the gutters.

Laying waterproofing carpet

Regardless of the angle of the roof, in the valley and along the slope, a waterproofing underlayment must be laid. It is sold in meter wide rolls. An adhesive is applied to the underside, covered with a protective film or paper. Before laying, the paper is removed, the valley carpet is glued to the flooring.

Installation of a waterproofing carpet begins with laying it in the valley. Roll out the material of a meter width, distributing 50 cm on both sides of the bend. Here it is desirable to do without joints, but, if necessary, the overlap of two canvases should be at least 15 cm. Laying goes from bottom to top, the junction is additionally coated with bitumen mastic, the material is well pressed.

Next, a waterproofing carpet for flexible tiles is laid along the cornice overhang. The minimum width of the carpet on the cornice overhang is the size of the overhang itself, plus 60 cm. First, the carpet is rolled out, if necessary, cut, then the protective film is removed from the inside and glued to the substrate. Additionally, they are fixed along the edges with stainless steel or galvanized nails with a large flat hat (step 20-25 cm).

In places of a horizontal joint, the overlap of two canvases is at least 10 cm, in the vertical direction – at least 15 cm. All joints are additionally coated with bituminous mastic, the material is compressed.

Lining carpet

The lining carpet, as well as the waterproofing carpet, is sold in rolls of meter width, the back side is covered with an adhesive. The laying method depends on the slope of the roof and on the profile of the selected shingles.

- If the slope of the soft tile roof is between 12° and 18°, the lining carpet is laid over the entire roof area. Installation starts from below, from the laid waterproofing carpet. The overlap of the panels is 15-20 cm. The joints are additionally smeared with bituminous mastic, the upper edge is fixed with nails (galvanized or stainless steel) with a flat cap.

With a small slope of the slope, the lining carpet is solid - With a roof slope of more than 18°, the lining carpet is laid only in places where the roof is bent. In the area of u50bu50bthe ridge, ribs, kinks of the slope, a whole roll of a meter wide is spread, distributing the material XNUMX cm from the inflection line. A roll cut in half is used along the gables and junctions to the walls – a strip XNUMX cm wide.

With a slope of more than 18 °, the carpet is rolled out only in places where the roof is bent

When using shingles with cuts (such as Jazz, Trio, Beaver tail), regardless of the slope, the lining carpet is spread over the entire surface of the roof.

Underlayment installation often requires undercutting. This is done with a sharp knife. In order not to damage the material below when cutting, enclose a piece of plywood or OSB.

Fronton (end) plank

Gable strips are mounted on the side sections of the overhangs. These are strips of metal bent in the form of the letter “G”, along the fold line of which there is a small protrusion. They cover the laid roofing materials from wind loads, from moisture ingress. The gable plank is laid on the flooring over the lining or waterproofing carpet, fixed with nails (stainless steel or galvanized) in a checkerboard pattern with a step of 15 cm.

These planks also come in pieces of 2 m, stacked with an overlap of at least 3 cm.

Slope marking

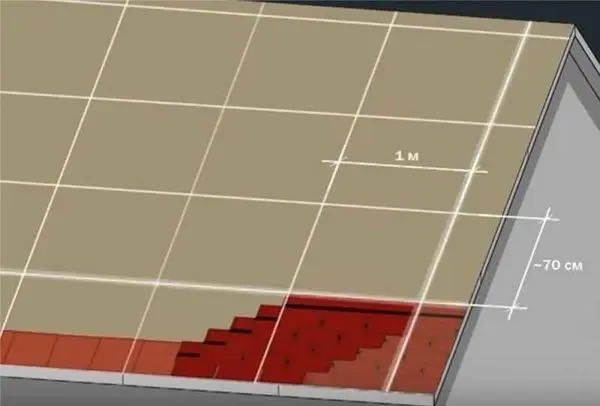

To make the installation of soft tiles simple, markings in the form of a grid are applied to the lining carpet or flooring. Do this with a painter’s cord. The lines along the cornice overhang are applied at a distance equal to 5 rows of tiles, in the vertical – every meter (the length of one flexible tile shingle). This marking makes laying easier – the edges are leveled along it, it is easier to track distances.

Valley carpet

On top of the already laid waterproofing carpet, another valley material is laid. It is slightly wider, serves as an additional guarantee of no leaks. Without removing the protective film from the underside, it is laid, cut at the bottom in the overhang area, and the boundaries are marked. Deviating from the mark of 4-5 cm, a special mastic of increased fixation Fixer is applied. It is applied from a syringe, with a roller, then rubbed with a spatula into a strip about 10 cm wide.

A valley carpet is laid out on the mastic, the folds are smoothed out, the edges are pressed. Stepping back from the edge by 3 cm, it is fixed with nails in increments of 20 cm.

Connection to a brick pipe

To bypass pipes and ventilation outlets, patterns are made from a valley carpet or galvanized metal, painted in the appropriate color. The surface of the pipe is plastered, treated with a primer.

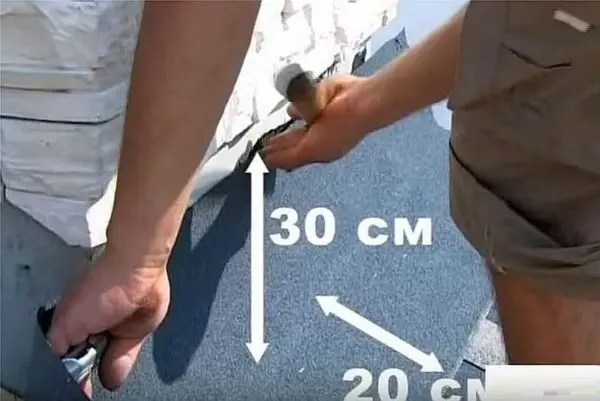

When using a valley carpet, a pattern is made so that the material enters the pipe by at least 30 cm, and at least 20 cm should remain on the roof.

The pattern is smeared with bitumen mastic, placed in place. the front part is installed first, then the right and left.

Part of the side elements is wrapped on the front part. The back wall is installed last. Its parts go to the side.

With proper installation on the flooring around the pipe, a platform is obtained, completely covered with a valley carpet. Before laying tiles in this place, the surface is smeared with bituminous mastic.

The tile from three sides enters the laid carpet, not reaching the walls of the pipe 8 cm.

The upper part of the junction is sealed with a metal strip, which is attached to the dowels.

All gaps are filled with heat-resistant sealant.

Conclusion of round pipes

For the passage of ventilation pipes there are special passage devices. They are positioned so that the lower edge of the element extends over the tile by at least 2 cm.

Having attached the passage element to the roof, its inner hole is circled. According to the applied contour, a hole is cut in the substrate, into which a round pipe is led out.

The back of the skirt of the passage element is smeared with bituminous mastic, set to the desired position, and additionally fastened around the perimeter with nails. When installing soft tiles, the penetration skirt is smeared with mastic.

The shingle is cut as close as possible to the ledge of the penetration, the gap is then filled with mastic, which is covered with a special UV-protective dressing.

starting strip

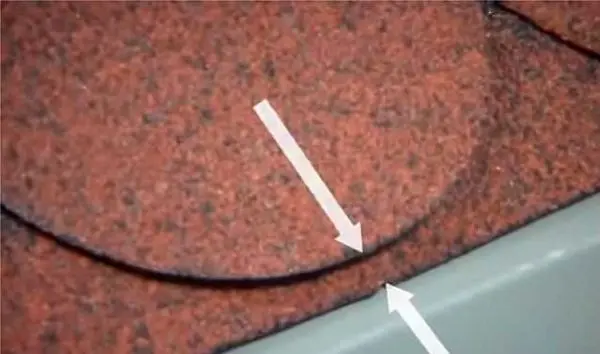

The installation of soft tiles begins with the laying of the starting strip. Usually it is a ridge-cornice tile or an ordinary one with cut petals. The first element is laid on one of the edges of the slope, going to the edge of the gable plank. The lower edge of the starting strip is laid on the drip, stepping back from its fold 1,5 cm.

Before installation, the protective film is removed from the back, the shingle is leveled and laid. Each section of bituminous tiles is fastened with four nails – at the corners of each fragment, stepping back from the edge or perforation line 2-3 cm.

If a cut from an ordinary tile is used as a starting strip, in some part of it there will be no adhesive composition. In these places, the substrate is smeared with bituminous mastic.

Installation of soft ordinary tiles

There is a flexible tile with an applied adhesive mass, protected by a film, and there is a composition that does not require a protective film, although it also fixes the elements well on the roof. When using the first type of material, the film is removed immediately before installation.

Before laying bituminous tiles on the roof, several packs are opened – 5-6 pieces. Laying is carried out from all packs at the same time, taking one shingle from each one in turn. Otherwise, there will be pronounced spots on the roof that differ in color.

The first shingle is laid so that its edge does not reach the edge of the starting strip by 1 cm. In addition to the adhesive composition, the tiles are also fixed with roofing nails. The number of fasteners depends on the angle of the slope:

- With a slope of 12° to 45°, each shingle is nailed with 4 nails. The nails are nailed 2,5 cm away from the visible part of the tile. It turns out that one nail “holds” two tiles.

Scheme of fastening soft tiles - If the slope is more than 45°, nails are driven into each tile. The exact layout of fasteners depends on the shape of the cut.

The location of fasteners on steep slopes

When installing soft tiles, it is important to drive in nails correctly. Hats should be pressed against the shingle, but not break through its surface.

Valley design

With the help of a paint cord in the valley, an area is marked in which nails cannot be driven in – this is 30 cm from the middle of the valley. Then mark the boundaries of the gutter. They can be from 5 to 15 cm in both directions.

When laying ordinary shingles, nails are driven in as close as possible to the line beyond which nails cannot be hammered, and shingles are trimmed to the floor of the gutter laying line. To prevent water from flowing under the material, the upper corner of the tile is cut obliquely, cutting off about 4-5 cm. The loose edge of the tile is smeared with bituminous mastic and fixed with nails.

Decoration of the pediment

On the sides of the slope, the tiles are cut so that 1 cm remains to the edge (protrusion) of the end plank. The upper corner of the shingle is cut in the same way as in the valley – a piece of 4-5 cm obliquely. The edge of the tile is smeared with mastic. A strip of mastic – at least 10 cm. Then it is fixed with nails, like the rest of the elements.

Installation of the skate

If the flooring in the area of the ridge is made solid, a hole is cut along the ridge, which should not reach the end of the rib 30 cm.

It is fixed with long roofing nails. On a long skate, several elements can be used, they are joined end-to-end. The installed metal ridge is covered with ridge tiles. A protective film is removed from it, then the fragment is fixed with four nails (two on each side). The installation of soft tiles on the ridge goes towards the prevailing winds, one fragment overlaps the other by 3-5 cm.

The ridge tile is a ridge-eaves divided into three parts. A perforation is applied on it, a fragment comes off along it (first bend, press the fold, then tear off).

The same elements can be cut from an ordinary tile. It is divided into three parts, not paying attention to the drawing. At the resulting tiles, a corner is cut off – about 2-3 cm on each side. The middle of the fragment is heated with a building hair dryer on both sides, placed in the middle on a bar and, gently pressing, bend over.

Ribs and kinks

The ribs are covered with ridge tiles. A line is beaten off along the bend at the required distance with a masking cord. The edge of the tile is aligned along it. Laying of flexible tiles on the edge goes from bottom to top, each fragment is glued, then stepping back from the top edge of 2 cm, fixed with nails – two on each side. The next fragment comes to the laid 3-5 cm.