Contents

All beekeepers, when preparing honey for sale, sooner or later face such a problem as crystallization of the finished product. It is important to know how to heat up a candied product without losing the quality of the product. For this, special devices are used – decrystallizers. They can be purchased at specialized stores or made independently.

What is a decrystallizer and why is it needed

Honey decrystallizer is a device that allows you to heat up a crystallized, “candied” product. All beekeepers face this problem, because some types of honey lose their presentation in just a few weeks. Crystallized goods are very reluctant to buy, but using a decrystallizer, you can return it to its original appearance and viscosity, which will make the product attractive in the eyes of buyers.

The device well dissolves crystals, consisting mainly of glucose. The heating process itself is far from a new invention, known to beekeepers for a long time (honey was heated in a steam bath).

In order to melt the glucose crystals, the mass must be evenly heated. This principle underlies the operation of all devices without exception. The desired heating temperature can be achieved in several ways. Optimal performance is not more than + 40-50 °C. All decrystallizers are equipped with thermostats that turn off the power to the device when the desired temperature is reached.

Types of decrystallizers

Today, beekeepers use several types of devices. They differ from each other mainly only in the way of application and form. You can use any kind with equal success, especially if you do not need to process a large amount of honey.

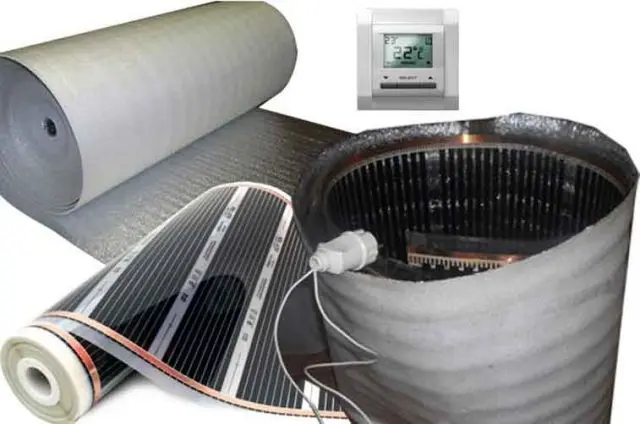

Flexible external decrystallizer

In simple words, this is a wide soft tape, inside of which there are heating elements. The container is wrapped with a tape and the device is connected to the network. Such a honey decrystallizer is very well suited for a 23 l cubetainer (standard).

Submersible spiral

The device is intended for work with small volumes of a product. The principle of operation is extremely simple – the spiral is immersed in a crystallized mass and heated, gradually melting it. So that the spiral does not overheat and burn out, it must be completely immersed in honey. In the honey mass, it is necessary to make a hole for the spiral, after which it is placed in a recess and the device is connected to the network.

Thermal camera

With this device, several containers can be heated at the same time. Vessels are installed in a row, wrapped with a cloth on the sides and top. Inside the web there are heating elements that heat the product.

Case decrystallizer

It is a collapsible box. Heating elements are fixed on its walls from the inside.

Homemade honey decrystallizer

The device is not particularly difficult, it can be made by hand. Factory decrystallizers are expensive, making the device yourself will help save money for novice beekeepers.

Which decrystallizer is better

There is no single answer to this question – each device is good in its own way in different situations. For example, for processing honey in small volumes, a simple spiral apparatus or a flexible tape designed for one container is suitable. For a large volume of product, it is advisable to use large-sized housing infrared devices or heat chambers that have the following advantages:

- The heating element does not come into contact with the product.

- Uniform heating of the entire mass.

- The presence of a thermostat that allows you to control the temperature and avoid overheating of the product.

- Simplicity and convenience in work.

- Compact size.

- Economical electricity consumption.

Thus, the choice depends mainly on the volume of processed products.

How to make your own honey decrystallizer

Buying a device of any type is not a problem – everything is on sale today. But buying a good factory decrystallizer will cost a lot. A weighty argument to save money, this is especially important for a novice beekeeper. Moreover, there is nothing complicated in making a home-made decrystallizer.

Option 1

To make a decrystallizer, you will need the following materials:

- ordinary foam for floor and wall insulation;

- roll of adhesive tape;

- wood screws;

- universal glue.

The assembly process is extremely simple: an oven-box of the required dimensions with a removable lid is assembled from foam sheets using glue and adhesive tape. A hole is made in one of the walls of the box for the heating element. As such, it is best to use a thermal ceramic fan heater. With the help of a home-made unit, despite its simple design, you can efficiently and efficiently heat honey. The only drawback of homemade products is the lack of a thermostat, the temperature of honey will have to be constantly monitored so as not to overheat the product.

Option 2

In this design, a soft infrared warm floor is used to heat honey. You can connect a thermostat to the tape, with which you can control the temperature. To prevent the heat from escaping too quickly, a heat-reflecting material is placed on top of the warm floor – isospan, with the shiny side up. For enhanced thermal insulation, isospan is also placed under the container and on top of the lid.

Option 3

A good decrystallizer can come from an old refrigerator. Its body is already equipped with good thermal insulation, as a rule, it is mineral wool. It remains only to place a heating element inside the case and connect a thermostat to it, you can use a temperature controller for a home incubator.

A self-made decrystallizer will cost much less than a factory counterpart. Of the shortcomings of homemade products, only the absence of a thermostat can be noted, which not everyone can install and correctly configure. Otherwise, a home-made device is cheap, practical and convenient. After all, each beekeeper in the process of designing and assembling immediately adjusts the device to fit his needs.

Conclusion

A honey decrystallizer is a necessary thing, especially if honey is produced for sale. After all, natural honey, except for single varieties, begins to crystallize in a month. During this time, it is not always possible to sell the entire product. The only way to return it to its normal presentation and viscosity is proper heating and dissolution. In this case, it is desirable that the heating element does not have contact with the honey mass.