Contents

The cow milking machine helps to mechanize the process, speed up the procedure for servicing a large herd. You can’t do without equipment on a farm. Recently, machines have become in demand among private traders containing more than two cows. Milking machines are available commercially, and experienced craftsmen sometimes fold them themselves.

Organization and technology of milking cows

The efficiency of a dairy farm depends on the technology of milking cows. There are two ways:

- Hand milking is not used on modern farms. The method has been preserved in private farmsteads, where they keep 1-2 cows. The manual process requires a lot of time, the presence of milkmaids.

- Mechanical milking speeds up the milk production process by 70%. Milk yield is increased by 16%. One operator with a milking machine is able to serve several cows.

The correct approach to the organization of milking increases the milk productivity of cows, prevents mastitis, and improves the working conditions of the attendants.

On large farms, it is customary to milk twice a day. It is important to maintain an equal interval between processes. Each milking is carried out at the same time. The herd is prepared in advance. Cows are formed in groups, each of which includes animals of approximately the same calving dates. They live in separate sections, receive a specialized diet of feed.

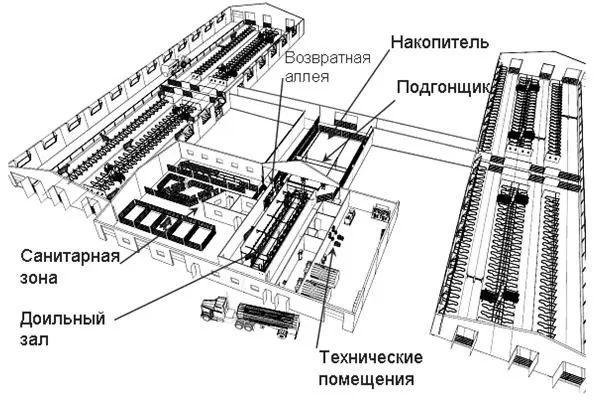

Depending on the conditions of keeping cows, the organization of milking differs. On a farm, animals can be serviced by a team or several heads are assigned to milkmaids. For workers, one or two shifts are established. The milking process depends on the machines used, the method of keeping cattle. Most farms use linear milking with stationary machines. Cows at this time are on a leash.

Types of equipment for milking cows

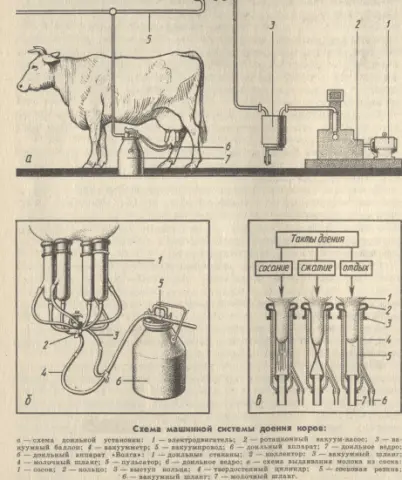

There are many models of milking machines. The equipment differs in performance, design, price, but works on the same principle. The machines are equipped with a low pressure vacuum pump. It is connected by hoses with milking cups. During operation, the pulsating air pressure in the cups compresses and unclenches the elastic inserts around the cow’s udder teats. The milking process begins. Milk through other hoses from the glasses is discharged into a container.

It is economically justified to use machines on large farms or private farms where more than three cows are kept. It is not profitable to buy a device for one animal because of the high cost. Machines differ in several ways:

- Milk is collected in a container, but it can be stationary and portable. To serve a small number of cows, mobile machines with a can are used. On large farms, the devices are connected by pipeline to a stationary tank.

- Each machine is able to serve a certain number of cows at the same time. In private yards and small farms, machines are used that are designed for milking one or a maximum of two animals at once. For large farms, equipment is in demand, to which more than 10 cows are connected at the same time.

- Vacuum pumps are used in three types. Membrane models are the cheapest, but inefficient. Piston models are powerful, but noisy and are large. The most popular are rotary models. Pumps are dry and oil.

- Machines have two or three cycles of milking. The first option creates squeezing and unclenching of the cow’s teat. The second option has a third phase of rest between compression and unclenching of the nipple.

- Machines differ in two ways of milking. The quality process is based on sucking milk with a vacuum created by a pulsator and a centrifugal pump. For cheap equipment, pressure surges are created due to the operation of a piston-type pump.

- Milking equipment is mobile and stationary. The first type resembles a cart on wheels, which is rolled around the farm. Stationary machines are installed in a permanent place, connected by a pipeline to a large milk collection tank.

A suitable type of equipment is selected so that it pays for itself, copes with the tasks.

Modern technologies for milking cows

Manual milking is a thing of the past, it remains only in private yards where they keep 1-2 cows. Modern milking technologies are based on the use of equipment. In addition, the process itself occurs according to several schemes:

- Milking is carried out inside the cowsheds by mobile devices transported on trolleys. Cows are kept on a leash.

- The place of milking and the type of keeping of cows is similar, only milk is collected in portable buckets or milk pipelines, for example, UDM – 200.

- Milking is carried out when the cows are in specially equipped rooms. For animals, loose housing is used.

- If a stall-pasture system for keeping cattle is chosen, milking is carried out in the barn in winter. In summer, cows are placed in a specially equipped stationary camp for milking. Milking is performed by machines with parallel passage teat cups.

- Robots are considered to be the latest cow milking machines that create a voluntary milking system.

The choice of technology is carried out taking into account the relationship of the apparatus with the sequence of the milking procedure, as well as the initial processing of milk.

Pros and cons of cow milkers

The advantage of using machines is the simplification of the work of a milkmaid. Productivity increases, milk yield increases, milk quality improves. Machine milking is less irritating to the teats as the process is closer to feeding a calf.

The disadvantage is cases of injury to the nipples. In addition, not all cows are suitable for machine milking. The problem is related to the structure of the nipples. If the technology is violated, then the use of the device increases the risk of a dangerous disease in a cow – mastitis.

The video shows the mechanized process:

How to make a do-it-yourself cow milking machine

For the manufacture of the device, you need to buy ready-made components. You cannot do them on your own. Additionally, you will need a lot of knowledge about the principle of operation of the equipment. Mistakes made will negatively affect the health of the cow.

For a homemade machine, you need to purchase:

- Electric motor driving the pump.

- Dry or oil vacuum pump.

- Belt for transmitting torque from the motor to the pump.

- Vacuum hoses for transporting milk.

- Receiver or vacuum bottle. The node smooths out air pressure surges in the system.

- Vacuum gauge. The device helps to control the pressure, maintain the parameter at the level of 50 kPa.

- Mounted equipment. The unit consists of a collector, teat cups, and a pulsator.

- Can made of aluminum or stainless steel for collecting milk.

- Pressure adjustment regulator.

- A valve to start air inside the can.

All units of the machine are placed on a trolley with wheels. You can choose a ready-made version or weld from a profile pipe.

The assembly procedure of the machine consists of several steps:

- The trolley acts as a bed for all nodes. First, the pump and motor are bolted. The pulleys are connected with a belt. For tensioning the belt drive, the motor mount is adjustable.

- The vacuum hose connects the pump to the vacuum bottle. A vacuum gauge is embedded on the line, as well as a vacuum regulator. The nodes are rigidly fixed on the branch pipe coming from the vacuum cylinder.

- A hose is taken from the vacuum line to the pulsator. Another hose from the outlet of the pulsator is connected to the teat cups. A valve is placed on the lid of the can, an air tube is removed.

- The lid of the can is equipped with a pipe, a milk hose is put on. Its other end is brought to the collector.

The finished machine is tested before use. Check the operation of the nodes. The glasses are placed in a bucket of water, the pump is turned on. The liquid must be pumped into the can. It is important to measure the frequency of pulsations, bring it to normal. After setting up the equipment, glasses, milk hoses, and a can are washed with soapy water and then with clean water.

Rules for milking cows using machines

The use of milking machines requires compliance with a number of rules:

- before each procedure, the condition of the udder and teats is checked, washed with clean water;

- quickly attach milking cups;

- the first cows that have calved are milked, the next in turn are young individuals, high-milk, and finally animals with poor milk yield are left;

- with the arrival of the first portions of milk, they look for impurities of blood or flakes;

- during milking check the vacuum in the glasses;

- milking is carried out at one time, the repetition of the procedure is unacceptable;

- at the end of the milk supply, immediately turn off the machine, carefully remove the milking mills;

- after the process is completed, the teats are disinfected, the equipment is washed;

- the resulting milk is subjected to cooling, control its quality.

The machine is regularly subjected to check, technical inspection. At the time of milking, the equipment must be in good working order.

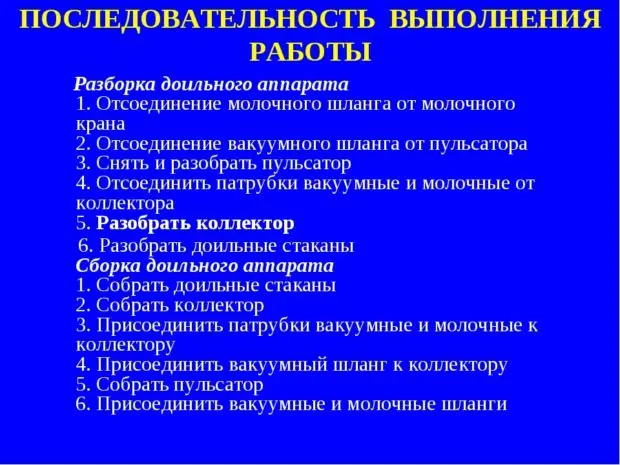

Maintenance of cow milking equipment

Timely care of the machine will extend its life. Well-maintained equipment will not harm the health of the cow. Any machine is provided with daily and periodic maintenance.

Daily maintenance includes flushing the system, as well as the surfaces of the machine components themselves. Washing the system before milking is carried out with water heated to a temperature of 90 оC. There is a complete disinfection, the glasses are warmed up. During the procedure, the operability of the equipment, the frequency of pulsations are checked. After completion of milking, a second wash is carried out. First, clean warm water is driven off, then a detergent solution and clean water again.

The best is the circulation method of washing the machine. It is commonly used on the farm. The process is based on alternately running water of different temperatures. At home, to flush the system, the glasses are simply lowered into a container of water, and pumping is turned on. For disinfection, a 0,1% chlorine solution is used.

Periodic maintenance is carried out once a week. All removable units of the machine are disassembled, manual washing is carried out with detergents.

If the machine is equipped with an oil-type pump, then periodic maintenance is complicated by timely topping up (once a week) and a complete replacement (once a month) of oil.

Conclusion

It is better to buy a factory-made machine for milking cows. Assembly from store nodes is not economically justified. In addition, a homemade product can work incorrectly.