Contents

There is nothing better than grilling shish kebabs in nature or on the lake in summer. For fans of this type of recreation, it is best to make a collapsible brazier with your own hands. How exactly to bring your own idea to life is described in our today’s article.

Advantages of collapsible models

Portable metal barbecues are the most popular, and there are a number of reasons for this:

- The product is easy to operate. It is easy to clean and wash from dust, and if necessary, it folds easily.

- Food is cooked quickly. Metal holds heat better than many materials, so food is fried evenly and quickly.

- The camping brazier is fireproof. Even if the hearth flares up strongly, it will not be able to spread – the metal will hold the fire.

- budget solution. Metal is one of the most affordable materials on the market today. Its price is much lower than that of its closest competitors – brick, stone and other materials.

- The speed of product creation. If the owner has welding, then in a couple of hours he will receive a finished product suitable for use. Whereas a brazier made of refractory bricks can be made in about a month, and you can use it a few days after the end of the work.

- Ease of transportation. The product is easy to rearrange in any room where it can be stored or operated. In any case, atmospheric phenomena will not be able to negatively affect it.

If you properly care for the brazier, then it can serve the owner for many years.

Video “Homemade collapsible brazier”

This video presents a detailed master class on making a collapsible brazier for a summer residence.

Manufacturing process

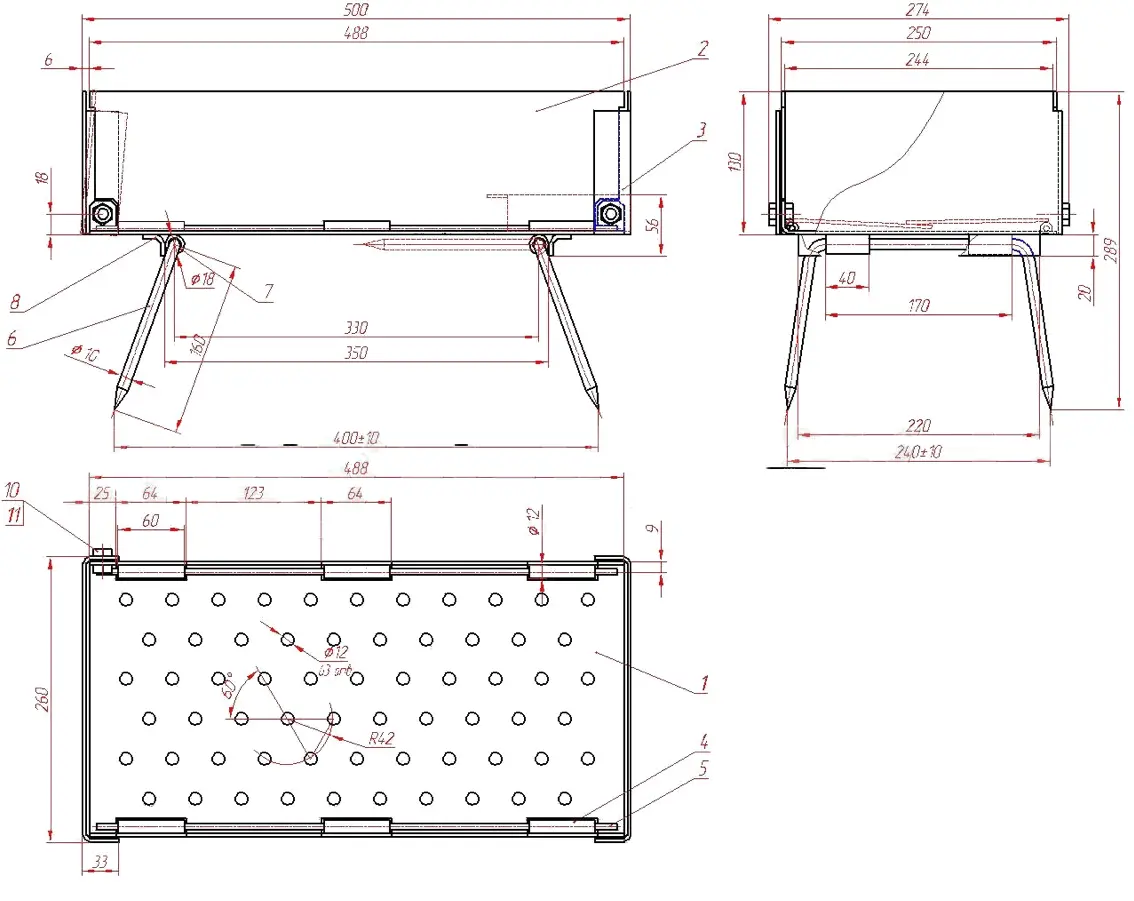

At the initial stage, you should create a drawing and determine the dimensions of the product. On average, 6 to 10 skewers with meat should fit on the grill. But you don’t need to make the brazier too long, because then the design will turn out to be cumbersome, and it will be difficult to carry it.

The width of the product should be such that the meat does not touch each other and the walls. The permissible height of the structure is 15–20 cm. These are the optimal parameters that allow you to put firewood on the bottom of the bowl, and skewers with meat on top, while they will not touch.

The folding brazier consists of the following parts:

- 2 side walls;

- 2 walls with legs;

- bottom.

For the manufacture you will need the following materials:

- several sheets of steel 3 mm thick;

- grinder or hacksaw;

- tape measure, ruler;

- corners and nuts;

- drill.

To create a conventional collapsible brazier, follow these steps:

- Mark the dimensions of the walls and bottom of the product on a sheet of metal.

- Cut the sheet with a grinder or hacksaw.

- Create grooves in the walls so that all parts of the brazier fit tightly.

- On the long walls we create several holes with a diameter of 1–1,5 cm.

- At the end, you need to connect all the parts together.

Folding brazier

The brazier-suitcase is done like this:

- A bottom is created: a cutout is made from steel according to the drawing, then shelves a few centimeters long are bent from all sides of the bottom.

- In the same way, the sides of the folding barbecue are created, only in them the shelves bend around at the bottom and on the sides, and a number of vertical slots are made on top.

- The walls are attached to the shelves of the bottom with the help of hinges. When folded, they stack on top of each other, and in the usual position they are placed at right angles to the bottom.

- The end walls are created in the same way, only the shelves are provided on the sides, and during transportation the walls are laid inside.

- At the final stage, one should not forget about the legs, which can be screwed to the bottom with nuts, and the handle, without which it will be difficult to move the barbecue.

prefabricated structure

Before you start cutting the structure with a grinder, you need to decide on the mounts for the barbecue. They are divided into two types: metal corners or canopies that are welded to the bottom.

The second option can be implemented, even if there is no welding machine nearby. In this case, a system of grooves is created that will help create a solid structure. But for this, even in the drawings, several protrusions measuring 1,5×3 cm, resembling the letter “G”, should be provided. In addition to this, you need to specify the places of the vertical cuts into which the fasteners will be inserted. Only after that it will be possible to cut parts from metal.

When all the details are created, all sections must be sanded. At the ends of the structure, it is better to immediately make holes for the handles. The final step should be painting the product.

As you can see, assembling a brazier with your own hands is a feasible task. You just need to accurately calculate the parameters of the product and have the skills to work with metal. By following simple rules, you can create the thing you need in the household.

Author: Svetlana Golitsina

Loading…