Contents

Any of the homeowners (baths, garages and other buildings are also considered) really wants his building to require repairs as rarely as possible. And first of all, the safety of the foundation is of concern. For this, it is important not only to plan and build correctly, but also to divert water – groundwater and precipitation. The drainage system is engaged in the removal of groundwater, and precipitation is removed using a blind area. This equipment is not the most complex device: any type of blind area is easy to do with your own hands. There is not a lot of work and costs, but it solves several problems.

Functions and tasks

We have long been accustomed to the fact that there should be a path around the house: it gives the whole layout a finished look. Especially if combined with the finishing materials that decorate the building. In addition, it is practical: you can walk along the path. And the fact that the path is a blind area, and its main purpose is water drainage – this is a successful combination of the properties and qualities of materials and a well-thought-out design.

If you look from a utilitarian point of view, then the blind area diverts rain and melt water from the foundation. The second very important practical task that can be solved with its help is to insulate the foundation. If you put insulation under the path, it will protect the house from freezing, which will greatly reduce heating costs.

When should a blind area be done? Immediately after finishing the exterior walls, but before finishing the plinth. Why is that? Because between the finish of the blind area and the wall of the house, a compensation gap is necessarily left. This is an excellent path for water that flows down the wall of the house (it hits the walls during slanting rain, for example). But it is impossible not to make this gap – the foundation will collapse. Sealing the gap is also unrealistic. The way out is to make sure that water does not get into the gap in any case. This can only be achieved if the plinth finish hangs over the seam. Then the water will drain a few centimeters further from the seam, and then fall into the drainage grooves. This can be done only if you first organize a blind area, and then bring the base to mind.

Why do we need a blind area of the foundation, when to deal with it, we figured it out, now it remains to understand how to do it correctly.

Blind area dimensions

It is necessary to remove precipitation from the foundation along the entire perimeter. Therefore, a protective belt is made around the house. The width of the blind area is determined depending on the type of soil on the site and on the length of the cornice overhang. In the general case, it should be 20 cm wider than the roof ledge. But SNiP established minimum standards: on normal soils, the width of the blind area is at least 60 cm, on subsidence – at least 100 cm.

Also in the manual for SNiP 2.02.01-83 there is paragraph 3.182 .. There are such instructions:

Blind areas along the perimeter of buildings should be prepared from local compacted soil with a thickness of at least 0,15 m. Blind areas should be arranged with a slope in the transverse direction of at least 0,03. The mark of the edge of the blind area must exceed the planning one by at least 0,05 m. Water entering the blind area must flow freely into the storm drain network or trays.

From this passage it is clear that the depth depends on the chosen technology, but cannot be less than 15 cm.

Technology devices

Any blind area consists of an underlying layer and a protective coating.

Bedding: what materials to use

The purpose of the sub-base is to create an even base for laying the protective coating. Its thickness is about 20 cm. Sand and gravel are often used for these purposes, but native soil or clay can also be used.

Sand and gravel are used on well-draining soils. In this case, sand is first laid, it is spilled and rammed. Then – a layer of rubble, which is also compacted.

If the soil in the area is clay or loam, then it is better to use native soil. If, with such soils, gravel or sand is laid around the foundation, then water will definitely be present near the house. Because it turns out that the density of the soil outside the underlying layer will be higher. This will cause water to accumulate under the blind area. If, with such a design, a drainage pipe is laid along the perimeter of the backfill, the problem will be solved. And effectively. But there will be more work, and the cost of the blind area with drainage is higher.

Types of protective coating

The coating for the blind area must meet many requirements:

- should not pass water;

- must be frost-resistant;

- have increased resistance to abrasion;

- should not be destroyed by water.

It can be paving slabs or paving stones. The shape and color can be very different – you choose based on the general design of the territory, the houses of nearby buildings. The thickness of these materials is at least 6 cm, only in this case they will withstand the harsh operating conditions.

You can use slabs or tiles made of natural or artificial stone, you can lay paths with large pebbles or pour gravel on top of all layers.

There is another type that is becoming increasingly popular – this is a soft blind area. It has few layers but works effectively. There may not be any solid and waterproofing layer on top: you can pour soil and plant grass or flowers. An interesting solution for a summer residence or a country cottage.

All these options are not bad, but the cost of their arrangement is quite high. If there is a need or desire to do it cheaply and cheerfully – your choice is a concrete blind area. There will be a lot of work, but the total cost is low.

General Principles

Depending on the soil on the site and the purpose of the building, different materials and layer structures can be used, but there are some points that are always present:

- the blind area has a general slope “from the house”, its minimum value is 3% (3 cm per meter);

- between the protective coating and the foundation there should be an expansion joint of 1-2 cm (lay roofing material in two layers, foam or XPS, fill it with sand, fill it with sealant);

- when performing waterproofing and insulation of the foundation, the material rises to the level of the blind area;

- the plinth should hang over the expansion joint and it should not join the protective coating (leave a gap of 1-2 cm).

Another popular type of protective coating for house formwork is paving slabs or paving stones.

How to make a blind area at home with your own hands

First, markings are made along the perimeter of the building with the help of pegs and laces. The following is the order of work:

- The vegetation layer and some soil are removed. The depth of the trench depends on the size of the underlying layer and the thickness of the protective coating. Usually – 25-30 cm.

- The bottom is treated with herbicides. This is necessary so that plants do not grow in this area. They are able to destroy even concrete and asphalt, and between tiles or paving stones they germinate instantly.

- The bottom of the trench is leveled, forming the required slope and compacted.

- The underlying layer is laid, rammed, keeping the slope. It is desirable to compact everything with a vibrating platform. Manual ramming is ineffective. Density is especially important when laying concrete, but it is desirable to compact it well under tiles or paving stones: it will not fall through and warp.

- A protective coating is being applied.

- A drainage groove is formed.

It is very short and schematic. Each coating has its own characteristics, and each needs to be discussed separately.

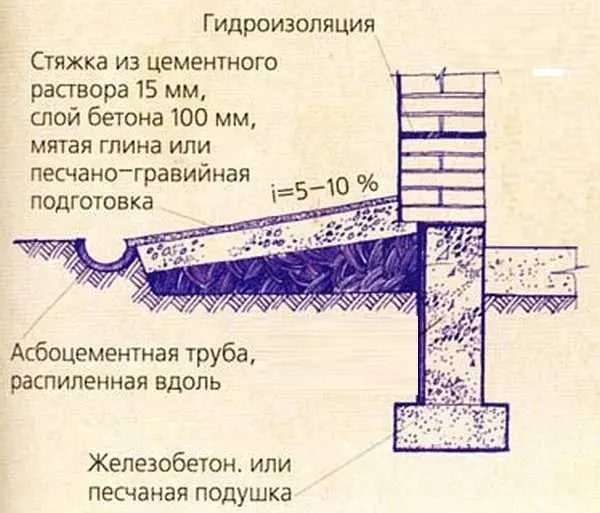

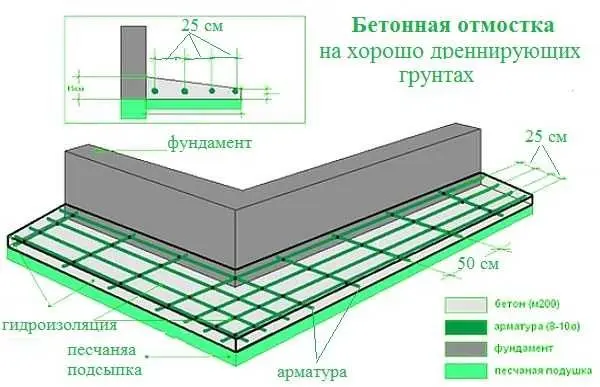

Concrete pavement around the house

The most widely used flooring is concrete. It turns out to be the most inexpensive. Traditionally, the sub-base consists of spilled compacted sand (10 cm) of sand over which compacted gravel (10 cm) is laid. As already mentioned above, such a scheme works normally on well-draining soils.

If there is clay or loam around the house, make the underlying layer from your native soil. To reduce the heaving effect and avoid cracking, pour 10 cm of sand over the compacted soil, and concrete is already laid on it. So concrete will crack less, but you will not get rid of cracking completely: especially in regions with harsh winters. In such conditions, it is better to make a blind area from crushed stone or pebbles – there will be no problems with cracking. If funds allow, they make it from tiles. For harsh winters, with properly selected substrate layers, they stand well.

In general, on heaving soils, it is desirable to make drainage that will drain water flowing from the tape. It will be an efficient and reliable solution. All the rest are only half measures. The drainage pipe is positioned so that water from the coating gets into it.

Blind area concreting rules

Formwork is installed and fixed along the perimeter of the marked zone. Most often, a board of sufficient height, fixed with pegs and spacers.

Reinforcement is often used to reduce surface cracking. To do this, a steel wire mesh with a cell of 10-25 cm is laid out on the finished underlying layer.

On top of the grid (if any), wooden planks treated with antiseptics are laid out. The thickness of the planks is 2,5 cm, and they can be processed with hot drying oil. These strips are damper joints that will prevent the concrete from cracking with temperature changes.

Planks are exposed with preservation of a bias from the house. Then they “pull” the rule along them, leveling the solution.

In order for the surface to be strong and even, ironing is carried out. Almost immediately after pouring, while there is still cement milk on the surface, concrete is sprinkled with cement (you can crush it several times) and rubbed with a trowel or plaster trowel. A thin, but strong, even and slightly shiny surface is formed on top. It is very resistant to abrasion.

The last step is concrete care. The path is covered with a damp cloth. During the week, it is regularly moistened (sprayed from a hose or watering can). The fabric must remain damp. In order not to suffer with watering, you can close the film, but it is more difficult to keep it in one place.

Concrete for blind area

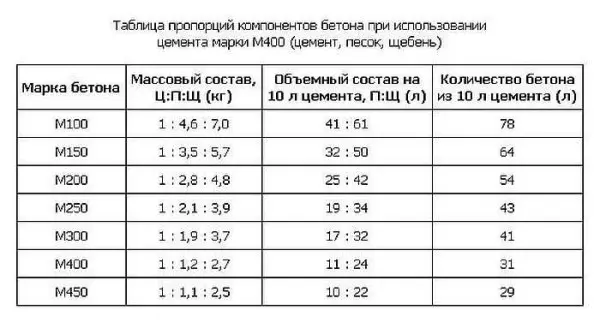

For the blind area, standard sand and gravel concrete is used. Gloom preferably not lower than M150. It is possible and higher: the higher the brand, the more durable the protective coating will be. The proportions of the preparation of the solution for the blind area can be selected from the table. They are given for concrete grade M400 – not very expensive, normal in terms of characteristics.

Insulated blind area

It makes sense to arrange an insulated blind area only in a house with heating. In the buildings of seasonal residence, in which the positive temperature is not maintained in winter, this makes no sense. The meaning of adding a double layer of insulation:

- create additional protection against freezing and reduce the likelihood of winter heaving;

- reduce heating costs.

How the insulated blind area works – it moves the freezing zone away from the foundation

If the insulated blind area of uXNUMXbuXNUMXbthe house is laid at the design stage, then another reason is added: if this part is available, reducing factors are applied when calculating the depth of the foundation. That is, the foundation has a lower height, and hence the cost.

A variant of the device of an insulated concrete blind area with a drainage system is shown in the video. Everything is painted normally, they just didn’t specify what to do if the layer of loose soil is more than 40 cm, which are required for the blind area. In this case, it must be covered with soil having a density higher than that located on the site. If there is clay on the site, then you can only use it. If it is loam, you can take either clay or loam.

One point: lay the clay not in a dry state, but diluted to a paste state. The technology is old, but nothing better has yet been invented. It is laid out in layers, trying to avoid the formation of air pockets – water will definitely stagnate in them (or someone will settle).

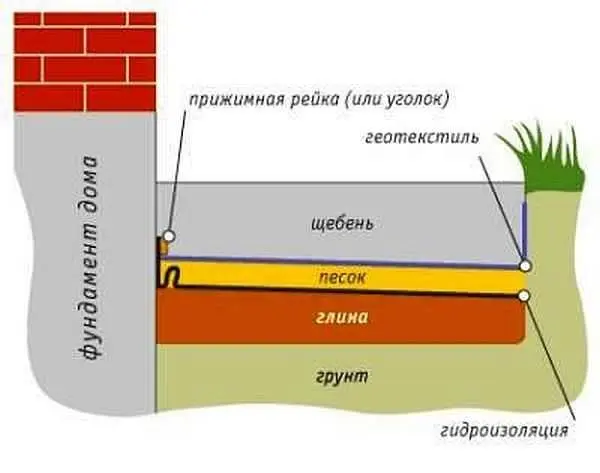

Blind area of crushed stone or pebbles

This is one of the types of soft blind area. It is easy to do it yourself. Such a system is used if there is a drainage system or the soil drains water well, and there is no clay or loam under the vegetation layer.

The order of work is this. A layer of geotextile is laid in a dug trench on a leveled and compacted bottom. This material is not thick, but very elastic. It will not allow crushed stone or pebbles to be pressed into the ground. And the track will not sag. Crushed stone is poured and compacted from above. Layer thickness 10-15 cm, fraction 10-80 mm. All.

If desired, the gravel blind area can also be made insulated. Then, EPPS (extruded polystyrene foam) 50 mm thick is laid in the trench on the compacted and leveled soil, a high-density geomembrane is laid on top, and pebbles or crushed stone can already be placed on it. But it is undesirable to walk on such a path.

Do-it-yourself blind area from tiles or paving stones

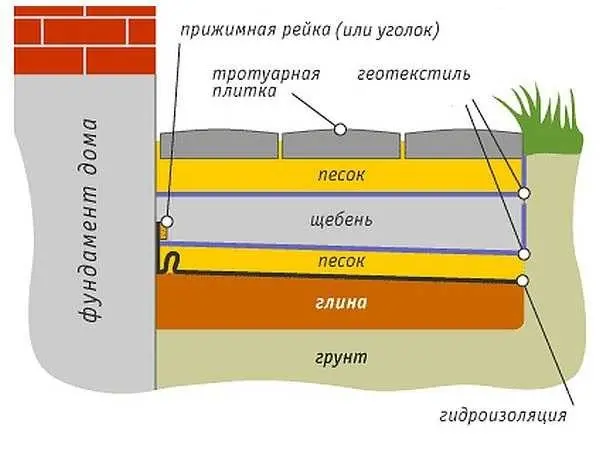

There are several options for the device, but the most optimal and versatile will be “pies” using geotextiles.

For example, one of them is shown in the figure. It can be used for blind areas on heaving soils with harsh winters. Note:

- both layers are attached to the wall with clamping strips;

- on the far side of the foundation, the geotextile rises to the ground level.

Foundation blind area for heaving soils

As a waterproofing, it is desirable to use geomembranes. They are made from high density polyethylene. By brand: you can take Tefond, Izostud, Fundalin, TechnoNIKOL Planter Standart, etc. They cost around 150-250 rubles / m2.

Geotextiles are available in different brands and densities, with different functional purposes. Choose based on the geology of the site. Their price is from 15 to 50 rubles / m2.

When arranging a blind area with your own hands, the main thing is to make sure that the water leaves the foundation, and does not collect in the sand or gravel layer near the house. What will definitely happen if the soil is fluffy (clay or loam), the underlying layer is made of sand and gravel, and there is no drainage.