Contents

Bee hives periodically have to be moved. It cannot be done manually: the bee dwelling, although not so heavy, is quite large and relatively fragile. In addition, the transportation of the hive should not disturb its inhabitants. Apilift is a special device designed for this kind of transportation.

What is apilift and why is it needed

Transporting a hive is not the easiest task. Since the structure is moved along with the inhabitants, such transportation must be carried out in compliance with many requirements:

- the trolley for transporting beehives must first of all have sufficient carrying capacity to move the bee dwelling;

- a prerequisite for the transportation of the apiary is the minimum mechanical impact, the apilift must guarantee minimal shaking and the softest possible lifting of the hive;

- the greatest danger during the transportation of the hive is the threat of collapse of the honeycomb, while not only the structure is destroyed, but insects also die, before transportation, all internal elements of the hive must be fixed, the same applies to external parts, if they cannot be disassembled beforehand, apilift for more reliable work equipped with special clamps;

- the ventilation of the hive is extremely important: this way it is possible to avoid overheating, the cart must provide normal ventilation, not be airtight.

The principle of operation is as follows: the trolley is brought close to the hive, the level of the bracket is adjusted so that it matches the position of the body. Then the hive is loaded onto the apilift with a winch, fixed and transported to another apiary.

The design of the bee trolley

The trolley for transporting the beehive is a steel structure, including a mobile part, a lifting block and a device for fixing the body. In any version of the apilift, there are the following elements:

- a static metal frame is the basis of the structure to which the rest of the parts are attached;

- 2 wheels mounted on an axle – the diameter of the latter depends on the dimensions and weight of the hive;

- a movable frame on which the hive is installed, as a rule, there are side clamps here that prevent the cargo from tipping over during transportation;

- the lifting block is a complex part of the apilift, it includes several blocks and levers that allow you to raise the hives;

- brackets – fixing devices;

- forks – support devices for lifting the hive, as a rule, they are removable to facilitate storage of the cart;

- clamps – the apilift is equipped with adjustable devices, this ensures reliable fixation of beehives of different sizes, in addition, this allows you to use the trolley to transport other large items, such as cans, barrels.

Models made in production are usually designed to transport cargo weighing up to 150 kg. Do-it-yourself apilifts are not so lifting. But hand-made production takes into account the individual characteristics of the beekeeper and bee hives.

How to make a do-it-yourself beehive cart

A ready-made hive lift is quite expensive. It is quite possible to assemble the structure yourself if you have the necessary parts. But at the same time, it is worth considering that in order to assemble the cart, you need to be able to handle the welding machine.

Necessary materials and tools

To make an apilift for beekeepers, you need to stock up on the following materials and tools:

- steel pipes with dimensions of 40 * 20, 30 * 20, 25 * 25 mm, it is preferable to choose galvanized products;

- cable for lifting device;

- forks – you can buy ready-made, as well as brackets;

- nuts and bolts M8 and M6;

- wheels of the appropriate diameter;

- springs and rollers on bearings;

- handles with rubber or rubber coating to prevent slipping, but you can do without them.

From the tools you will need a measuring tape, a key and, of course, a welding machine. A threaded connection is not used in the manufacture of apilift.

Do-it-yourself bee trolley (apilift): drawings with dimensions

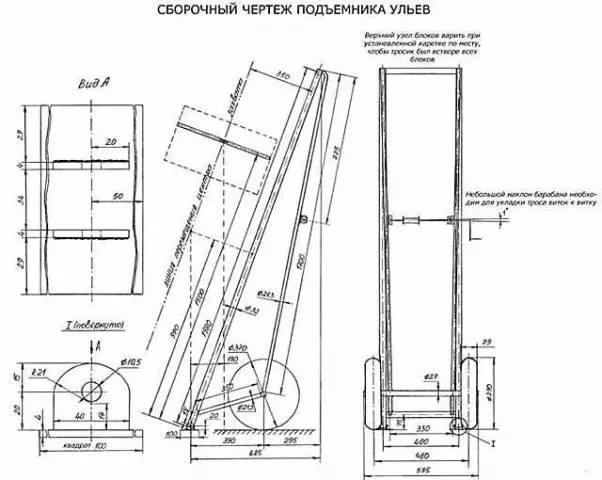

The construction of the hive trolley itself is relatively simple: a base frame, a block with wheels and a fork. But what is really difficult is the lift. Do-it-yourself drawings for making a do-it-yourself hive cart, in fact, are a diagram of the assembly of the lift.

Do-it-yourself step-by-step assembly of apilift

The procedure for building a do-it-yourself cart for beekeepers in general includes the following steps.

- Preparation of sources: processing, if necessary, and cutting metal pipes to size. Assembling side racks, main frame and block frame by welding.

- Construction of the lifting block for the hive and preparation for installation.

- Mounting on the frame forks, brackets, lift, wheels and handles.

- Checking the product for readiness for operation – transportation of an empty hive.

Assembly order may vary. In addition, different models may require the installation of additional parts.

Frame manufacturing

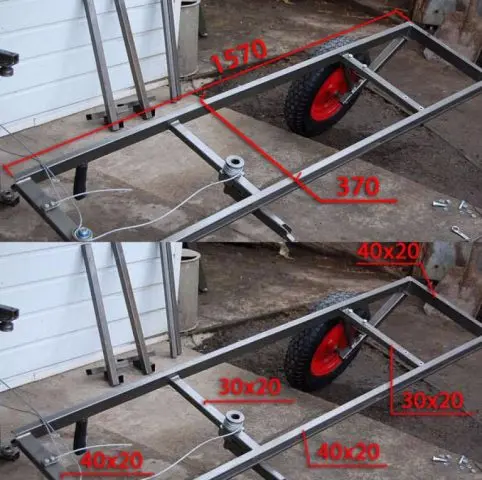

Do-it-yourself assembly of the apilift according to the drawing begins with the frame. Firstly, this is the base of the structure, and secondly, it is the easiest element to manufacture. Profile pipes are used for the frame. For a standard design with a load capacity of up to 120 kg, pipes with a cross section of 40 * 20 mm are sufficient.

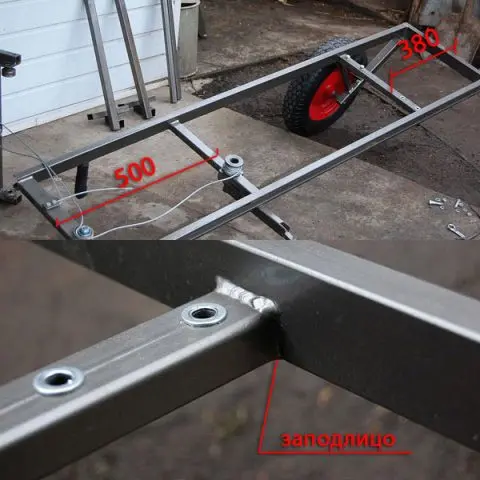

Pipes are cut according to the dimensions of the trolley – 1570 by 370 mm, as a rule. The parts are connected to each other so that right angles are maintained and welded. In this case, the upper transverse bar is welded vertically, and the lower one is flat.

On the outer side of both racks of the apilift, a cut is made with a width of 20 mm. The bearing axles will move along it.

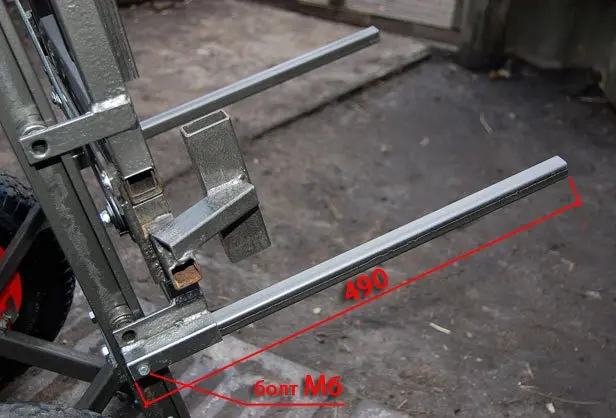

M6 bolts are screwed on the top of the racks – they serve as limiters and prevent accidental exit of the carriage beyond the boundaries of the rack. Stepping back from the top of the rack 20 cm, weld the handles for the bee cart.

Apilift is reinforced with two additional crossbars from a pipeline with a cross section of 30 * 20 mm: the lower one is fixed at a distance of 500 mm from the bottom of the frame, the upper one – 380 mm from the top one. Holes for the M8 bolt are drilled in the lower crossbar of the hive cart: brackets are attached here.

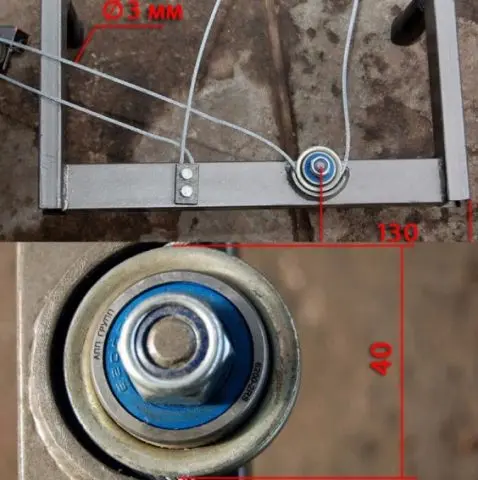

At the top of the frame on the front side, a roller with a bearing is rigidly fixed – it acts as a lifting block. A semicircular side is welded along the edge of the roller, which does not allow the cable to spontaneously fall off. The distance from the roller to the edge of the frame is 130 mm. A cable with a diameter of 3 mm enters the roller. At the same distance, on the other side, plates with bolts are fixed, where the free end is fixed.

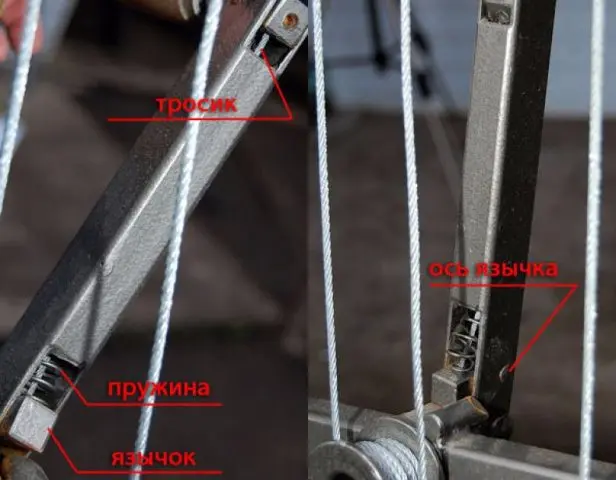

On the second lower crossbar of the apilift, at a distance of 120 mm from the edge, a coil 35 mm high is welded to wind the cable. Its axis is installed in the bearing, and a lever equipped with a handle is attached to the back side.

The handle is spring-loaded: the steel tongue is stuck in the stopper in a free state – a rod fixed next to the coil.

Lift block assembly

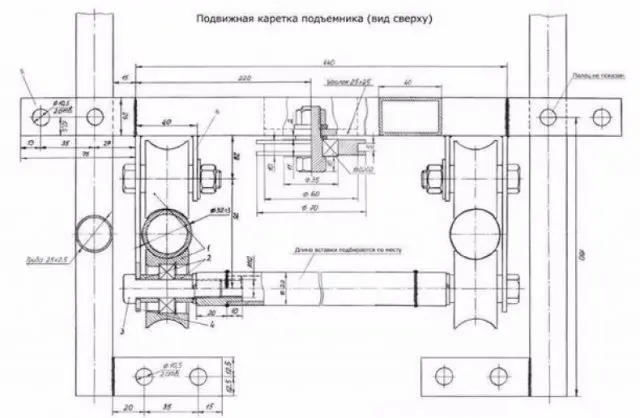

This is the most critical node of the hive cart. The block will require its own frame, welded from thinner and lighter pipes and 4 bearings.

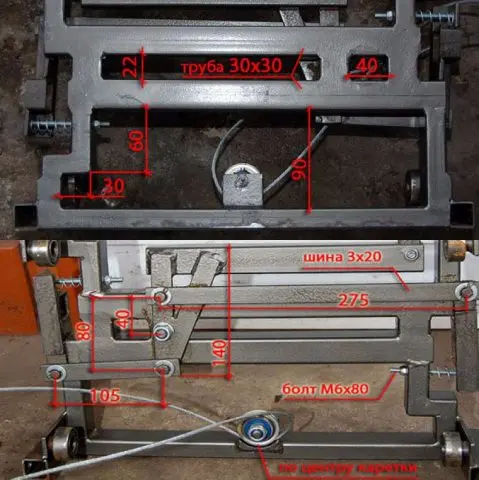

Pipes with a cross section of 30 * 20 mm are cut to size – 1720 by 380 mm and welded. The two lower crossbars are made of pipes 30 * 30 mm, this also includes side clamps. A coil is welded in the center of the lowest cross member, similar to the one that is placed on the top of the main frame of the bogie.

The apilift carriage moves on 4 bearings. For the latter, brackets are made from a 3 mm tire. The bearings must be free to move in the tubes of the side racks of the cart. Pieces of shaped pipes with a cross section of 25 * 25 mm are welded onto the lower brackets – the fork parts are inserted here.

Make hinges for side clamps. To adjust the angle of inclination, spring-loaded bolts are used: the more the hinge is inclined, the greater the gripping force. Clamps should be easily inserted through the hinges into the pipes. When it is required to fix the hive on the apilift cart, the clamps are brought close to the body and clamped. Forks are inserted into the carriage so that the hive can be placed. Fork length not less than 490 mm.

The compression mechanism is activated by a lever with a rod. In the drawings of the apilift, the design of the device is described in more detail.

Assembling the movement mechanism

This part of the hive cart is the simplest. The main thing is to choose the right wheel diameter.

An axle with a bearing is inserted into the wheel. From the outside, the axis is fixed with a nut, from the inside, a pipe 290 mm long is welded to the axis.

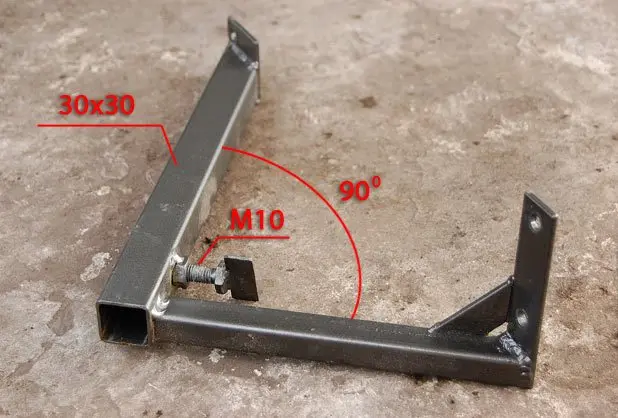

The bracket is welded – 2 pipes with a cross section of 30 * 30 mm at a right angle. At their ends, plates are welded for fixing to the frame.

The wheels are displaced relative to the bracket, thereby adjusting the angle of inclination of the apilift for the hives.

Conclusion

Apilift is an extremely useful device not only for the apiary, but also for ordinary summer cottages. In addition to beehives, it can carry very large barrels and cans, and other weights. Its design is not too simple, however, with the ability to use a welding machine, you can make an apilift yourself.