Contents

With the onset of winter, hand-held snow removal tools are in demand. This category includes all kinds of shovels, scrapers and other devices. You can buy them at any hardware store or assemble your own exclusive design. To help craftsmen, we suggest that you familiarize yourself with how to make a snow scraper, as well as a brief overview of existing hand tools.

What parameters to choose a scraper

The design of a manual scraper for snow removal can be different. Conventionally, such a tool can be divided into manual and mechanical models. The first option is ordinary snow shovels or scrapers with a handle, which you have to push with your hands in front of you. Mechanical scrapers also need to be pushed by hand, but they have wheels or skis. This makes the tool easier to move. In addition to adding a running gear, mechanical models are often equipped with a small blade instead of a scoop, which allows you to move the snow to the side.

There are three important requirements for any scraper design:

- light weight;

- structural strength;

- comfortable handle.

It should be borne in mind that any purchased snow-removing hand tool does not always surpass home-made counterparts in its characteristics. In some cases, it is even inferior in quality.

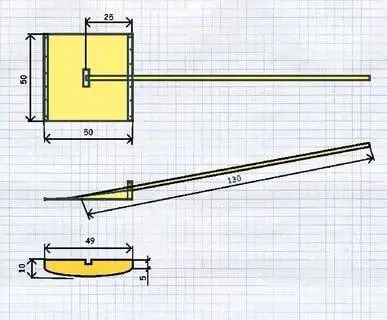

The easiest way is to assemble a shovel with a quick hand. If an aluminum sheet is available, a rectangular fragment with sides no more than 50 cm is cut out of it. The cutting is taken from an old shovel. It is carried out through a hole previously drilled in the center of the back side of the scoop. The end of the cutting, cut at an angle, is fixed with a self-tapping screw and a metal plate in the center of the scoop.

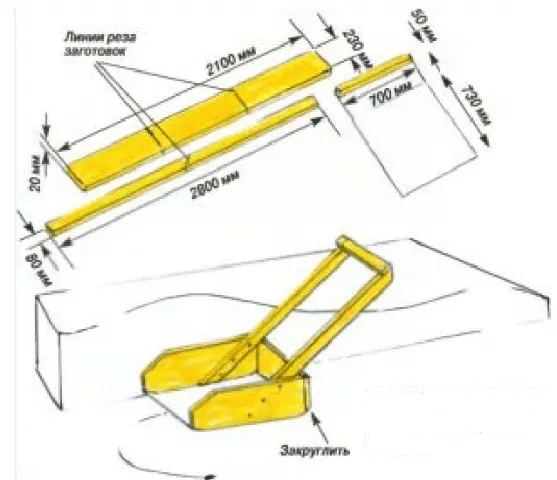

A wooden plywood shovel is made according to a similar principle. Only the sides are cut out of the board. The working edge of the scoop is sheathed with a steel strip. It will protect the plywood from abrasion on the ground. The handle is attached to the rear board from above, reinforced with a metal strip plate.

An example of a scheme by which you can make a wooden shovel can be seen in the photo. This project has a small improvement. The lower part of the tailgate is semicircular. This allows for a comfortable curved scoop shape.

Scrapers manufacturing options

A shovel is a good thing, but it is difficult to throw snow with such a tool. Let’s take a look at the options for improved factory and home-made scrapers.

Scraper blade on wheels

A mechanical blade scraper will require a wheelset with a metal frame. Where to get it from, there are many options. Any stroller or trolley for transporting bags will do.

First you need to make a dump, that is, the scraper itself. It is difficult to bend a steel sheet 2 mm thick, so it would be good to find a pipe with a diameter of 270 mm. First, cut off a piece 10–15 cm longer than the width of the frame. The dump should cover a strip such that the wheels after it roll over the cleared area.

A segment slightly less than a semicircle is cut out along a piece of pipe. To prevent the blade from scratching the tiles or asphalt, a conveyor belt is bolted to the lower part.

In the manufacture of the frame, the cart is altered so that four stops for the blade are formed: 2 at the top and 2 at the bottom. A wheel pair and a U-shaped handle are attached to the lower stops on the back side. The upper stops simultaneously form struts. Their one end is bolted to the handle, and the other to the hinges on the back of the blade. From the front side, the second ends of the lower stops are also fixed to the blade hinges.

The end result is a scraper, as shown in the diagram. All connections must be bolted only. Then, at any tilt of the handle, during operation, the blade will constantly lower itself to the ground.

Scraper improved by a brush

You can find such an interesting tool in a store or make it yourself. A scraper with a brush allows you to cleanly remove snow from paving slabs. In the store version, it can be a plastic shovel with a removable brush. Homemade design is a scraper of any configuration. Simply attach a stiff-bristled brush to the back of the blade or scoop. During operation, it will sweep up the remaining snow, which can then be easily removed with a shovel.

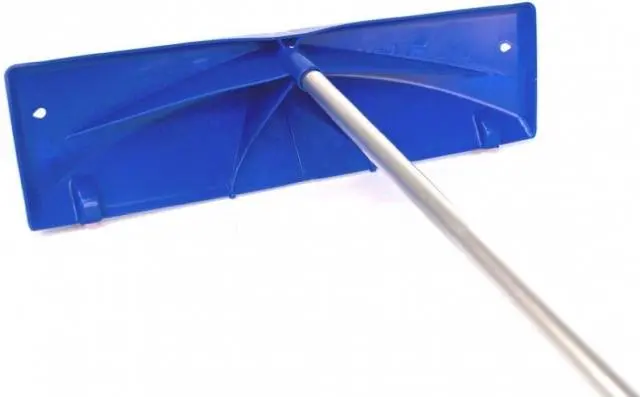

Factory made plastic scraper

According to the principle of operation, a plastic scraper resembles a blade, only it does not have wheels. The basis of the tool is a rectangular plane with stiffeners. A handle is fixed in the center of the scraper in the upper part. During work, a person simply pushes the snow away from himself with a plastic element or shovels it over himself.

Steel scraper on skis

The simplest construction of a steel scraper is shown in the photo. It consists of a rectangular aluminum sheet to which a U-shaped handle is attached. The disadvantage of the model is the high labor costs.

You can improve the tool by putting it on skis. To do this, runners from a steel corner, 1 m long, are attached to the U-shaped handle at the bottom. The ends must be bent up to make it look like skis. The scraper blade is attached to the handle so that the lower end of the aluminum sheet is on the runners.

The video talks about the quick manufacture of a scraper:

Snow scraper

In the presented drawing of the scraper, you can see that it is a conventional scraper with a U-shaped handle. The bucket is similar to a shovel, only with high sides. Snow removal is performed by pushing the scraper in front of you. The angled handle design reduces stress on the arms and back. Here, most of all goes to the legs of a person. The more snow in the bucket, the harder it is to walk to push it.

You can make a snow scraper with your own hands from the same plywood. But a wooden instrument saturated with moisture is very heavy. In addition, plywood wears out quickly when rubbed against asphalt. Here you can find two ways out: nail a galvanized sheet to the plywood from below or immediately bend the ladle from an aluminum sheet.

Conclusion

Of all the options for scrapers, homemade models are considered the most convenient, since the owner initially makes it according to his requirements.