Contents

It is not very easy to assemble a cultivator from old parts. Fitting of parts is required to make a workable assembly out of them. If a person’s hands grow from the right place, then it will not be difficult for him to make a home-made cultivator for him.

Varieties of motor cultivators

Before you start assembling your motor cultivator, you need to familiarize yourself with the varieties of equipment. It will depend on what nodes the homemade product will consist of and what tasks it will be able to perform.

The difference between cultivators by engine type

Two types of motors can be used on homemade cultivators:

- An electric motor is installed subject to the presence of a three-phase network. This technique is more suitable for small summer cottages, since a cable will constantly be dragged behind the cultivator, and you won’t go long distances with it. An electric motor is used with a power of at least 2 kW.

- The best option is a cultivator with an internal combustion engine. The technique will turn out completely not tied to the outlet. You can go far in the field or carry goods. Motors are petrol and diesel. If you can find an engine with a capacity of more than 4 liters. with., then from a homemade product you will get an excellent walk-behind tractor.

Having decided on the type of motor, you can begin to think about the design and functionality of the future cultivator.

The difference between motor cultivators according to the method of movement and soil cultivation

According to the method of movement, the technique is of two types:

- Self-propelled machines are equipped with a wheel pair with a drive;

- Non-self-propelled cultivators do not have drive wheels. Instead, working attachments, such as milling cutters, are put on a rotating shaft. With the help of them, the unit threshes the soil and at the same time moves forward.

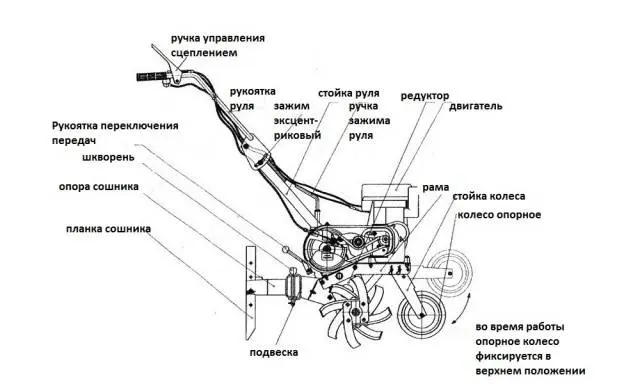

Self-propelled vehicles are difficult to manufacture. Even 2 gearboxes can be installed here. One of them use the speed. It is needed to rotate the rotary nozzle, which loosens the earth. With the help of the second gearbox, the driving wheels are set in motion.

Non-self-propelled cultivators have the simplest device. The movement is due to the rotation of the cutters. The unit has two wheels, but they are not leading, but simply serve as a stop for simplified movement. In general, a motor cultivator cannot be made without supporting wheels. It will constantly burrow into the ground. In addition, the support wheels help to regulate the soil cultivation depth.

If you have already decided to assemble a motor-cultivator with your own hands, then it is better to spend more time on making a model with drive wheels.

What you need to assemble a cultivator

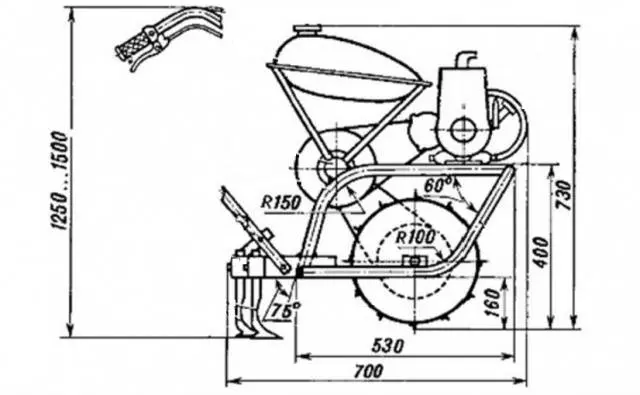

To assemble the cultivator yourself, you will need drawings of all nodes. An example of a diagram with dimensions is shown in the photo. You can look for other drawings of cultivators or develop your own.

An internal combustion engine for a cultivator is suitable from a moped, a powerful chainsaw or a motorcycle. If it is decided to make an electrical installation, then the motor will come from industrial ventilation or a compressor.

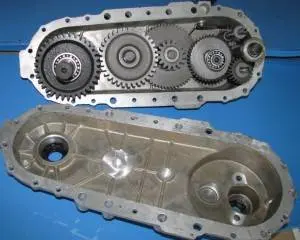

The gearbox is needed for any type of cultivator. Motor shaft speed is too high. The gearbox reduces the speed, due to which the force of rotation of the working shaft increases.

All components of the cultivator are mounted on the frame, and the equipment is controlled by handles. These elements are welded from a pipe or profile. The structure must be solid. Being overweight is not a hindrance. From this only there will be a better coupling of the wheels of the cultivator with the ground.

Assembling the electric cultivator

If you could not find a powerful electric motor, you can take 2 pieces of 1,5 kW each. After fixing on the frame, they are combined into a single system with belts. Only then a two-strand pulley is installed on one engine. From it, the torque will be transmitted to the pulley of the working shaft of the cultivator gearbox.

Rear wheels are persistent. They are simply fixed to the frame with an axle with bearings. Leading is the front axle of the cultivator. Cutters are put on here, transport wheels or lugs are placed.

The gearbox is perfect from a broken Neva walk-behind tractor. Before use, it must be disassembled to inspect the gears. Parts with broken teeth must be replaced.

The frame of the cultivator is welded from an ordinary steel pipe with a round section with a diameter of 32 mm. For handles, it is advisable to take a slightly thinner tube, with a diameter of about 20–25 mm. A mount for attachments is necessarily welded to the frame at the back. It can also be removed from a broken walk-behind tractor. Thrust wheels are suitable from agricultural equipment. Of the purchased materials, only a long wire is needed, through which electricity will be supplied to the motors.

Assembling a cultivator with an internal combustion engine

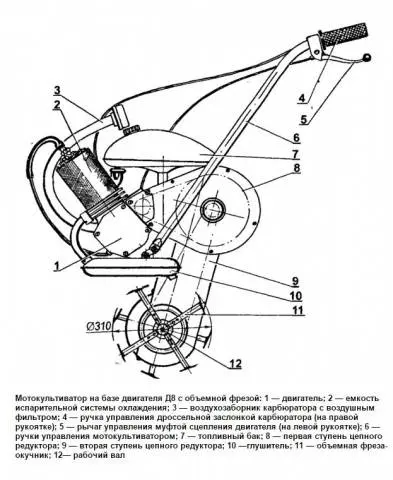

So, for a cultivator, an air-cooled internal combustion engine is needed. In our example, let’s take the D 8 model from an old moped. The photo shows a diagram of the cultivator. It can be used to determine the location of all nodes.

The assembly of a motor cultivator has almost the same steps that were taken in the case of using an electric motor. First, a frame with handles is made, and then the motor is mounted. It is designed for air cooling, but the cultivator moves at low speed and this is not enough. Before the engine, you need to install a fan or equip a metal water tank around the working cylinder. The device is primitive, but it will not allow the cylinder block to overheat.

The reducer for this motor cultivator is used chain with two steps. The asterisk is taken one native from a moped, and the other is a bicycle one. All rotating mechanisms are covered with a steel casing.

The video shows the process of making a cultivator:

The use of a creeper for a cultivator

The creeper is needed to reduce the speed of the cultivator. Most often it is in demand when working with attachments. This unit is bought factory-made or made independently. In general, to reduce speed, it is easier to put wheels of a larger diameter on the cultivator. If this option does not suit you, you can assemble a simple creeper:

- a box is assembled from steel sheets;

- inside, an axle with a mounted gear of a larger diameter is welded in than on the drive shaft of the cultivator;

- the box is bolted to the frame;

- now it remains to tighten the chain by connecting the driven and driving gears.

On this, the creeper is ready. You can put wheels, cutters and continue to work with a motor cultivator, but at a lower speed.

Troubleshooting the cultivator

Repairing a motor cultivator with your own hands is not difficult due to the simplicity of the design of the equipment. Let’s look at the most common problems and how to fix them:

- Cultivator motor does not start. This is usually due to a lack of spark. You should try replacing the spark plug. Another problem may be the lack of fuel supply due to clogged filters. They are dismantled, washed in gasoline, and then put in place.

- The motor stalls during operation. The cause again may be candles or poor fuel supply.

- An extraneous knock inside the engine indicates damage to one of the parts. The motor urgently needs to be disassembled to identify a malfunction, otherwise it will jam.

- A running engine makes a lot of noise and overheats. The reason may be a bad fuel mixture or a hanging load while operating the cultivator. The equipment is allowed to cool, and during this time new fuel is prepared.

- The cultivator does not move. Perhaps something is stuck between the cutters or wheels. Alternatively, the belt drive has loosened. If there are no such problems, then the problem is in the gearbox.

The video tells about the repair work:

Repairing a homemade cultivator is easier to do, since all the nodes were assembled independently. You know what they are made of. A complex breakdown of factory-made equipment is best left to the specialists of the service center.