Contents

For processing tree branches, tops of garden crops and other green vegetation, they came up with an excellent mechanical assistant – a shredder. In a few minutes, a pile of waste will turn into raw material for compost or poultry bedding for the winter. The factory-made unit is very expensive, so the craftsmen learned how to assemble it on their own. For those who are interested, we suggest considering how to make a garden shredder with your own hands at minimal cost.

The main components of the shredder

The grass and branch shredder consists of three main components: a motor, a cutting mechanism – a chipper, a hopper. All this is located on a steel frame and is closed by a casing for safety. Some models of factory-made shredders can be equipped with an additional hopper to collect the crushed mass. When working with a grinder, additional devices are used: a pusher for organics and a sieve that helps to separate small fractions. Screened large waste, if necessary, is loaded into a bin for recycling.

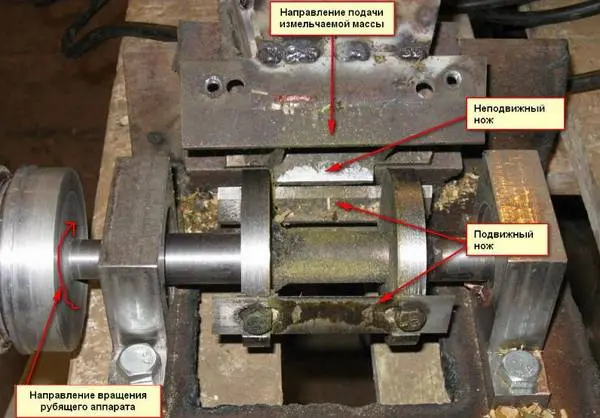

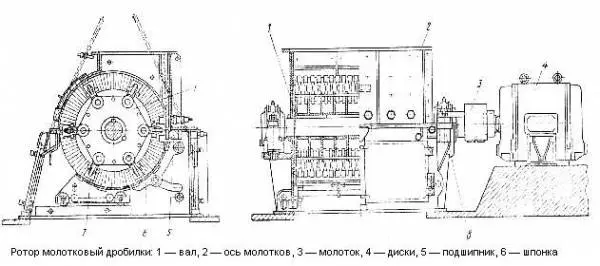

Factory-made shredders are equipped with roller, milling, hammer and other chippers. Homemade garden shredders usually work with a cutting mechanism made from a set of knives or circular saws.

shredder drive

Any grass and branch shredder is powered by a drive. There are only two options here: an electric motor or a gasoline engine. Electric shredders are much weaker in power and are more designed for grinding fine organics. Choppers powered by internal combustion engines are much more powerful. They are able to cope with branches up to 8 cm thick.

When making a garden shredder with your own hands, the electric motor can be removed from the old equipment. It is desirable that its power be at least 1,1 kW. Who has a walk-behind tractor, a shredder can be connected using a belt drive to the internal combustion engine. In the absence of any motor, your chopper will have to be equipped with a unit purchased in a store.

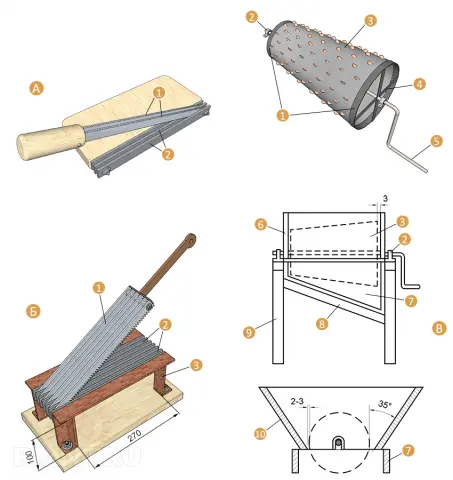

Soft organic grinders can, in general, be without a drive. A person puts them into action by hand power. Variants of such mechanisms are shown in the photo.

Drawings of different models of shredders

To make a grass chopper, you need to have accurate blueprints on hand. We propose to consider several options for shredder schemes.

A chopper with a hammer chipper is considered universal. The mechanism will cope with soft green mass, tree branches, thick tops of garden crops and even grain.

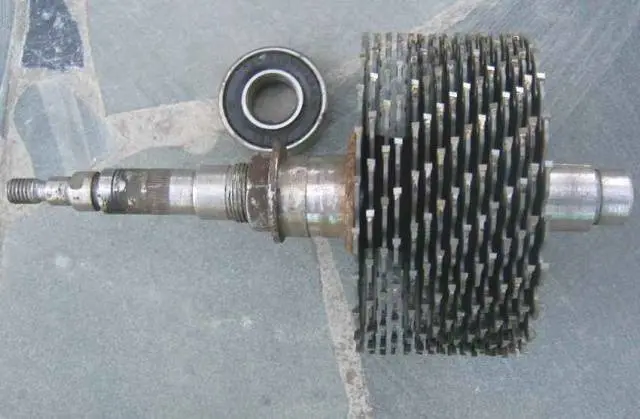

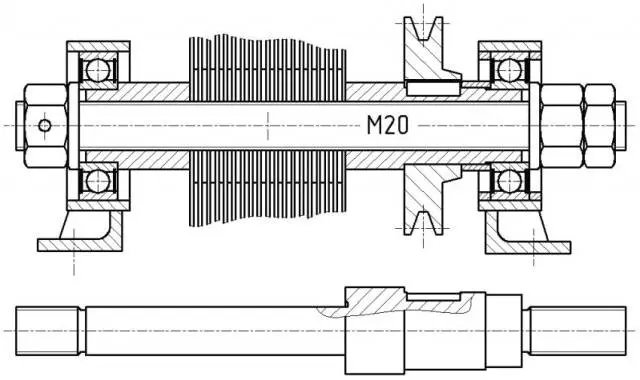

The easiest way to assemble a cutting mechanism for branches and grass is from circular saws. For such a chipper, even drawings are not needed. Circular saws in an amount of 15 to 30 pieces are mounted on a shaft, tightened on both sides with nuts, stuffed with bearings, after which the entire structure is mounted on a steel frame.

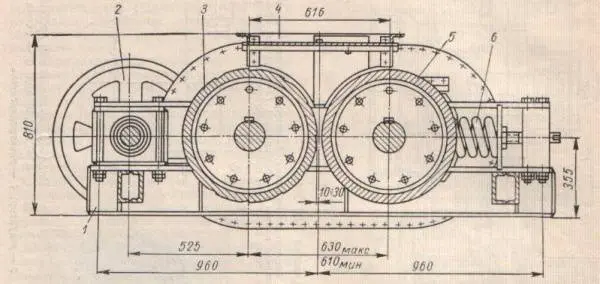

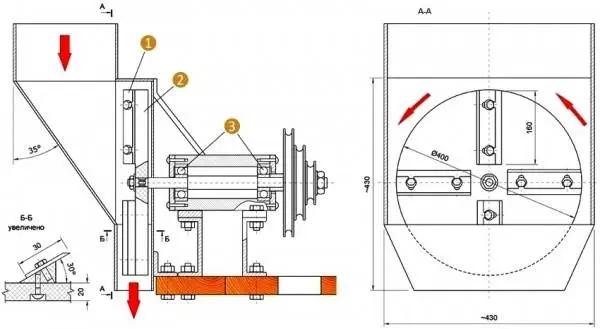

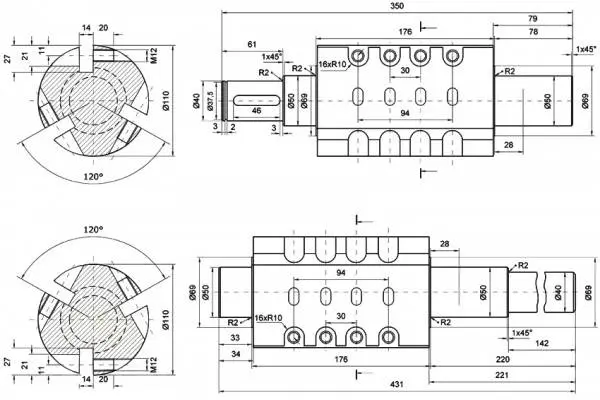

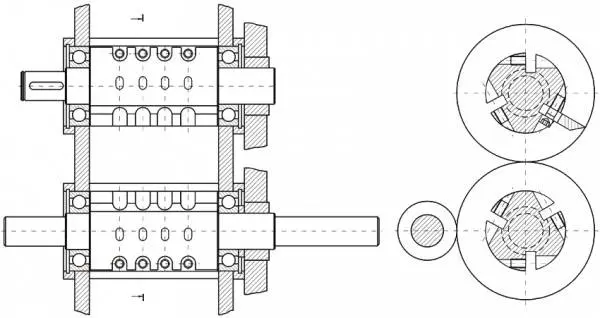

A two-roll chopper is also easy to manufacture. This can be seen from the drawing shown. The chipper consists of two shafts, on which steel knives are fixed from above. In home production, they are made from the springs of a truck and put in 3-4 pieces. The shafts on the axis and bearings are fixed parallel to each other so that during rotation the knives do not cling.

The video shows a homemade chopper with gears:

Instructions for assembling different models of shredders

Assembling a homemade garden shredder begins after all the details are prepared according to the drawing. Regardless of the chosen design, the work includes: the manufacture of the frame, the loading hopper, the chipper and the connection of the engine.

Circular saw construction

Such a garden shredder of branches consists of circular saws assembled into a single design. They will have to be bought at the store. The number of saws is determined individually. Usually put from 15 to 30 pieces. It is important to note one nuance here. From a larger number of saws, the width of the chipper increases, which means that a more powerful drive is required.

Circular saws are mounted on the shaft, and an intermediate washer 10 mm thick is placed between each. You cannot reduce the gap, otherwise the work area will decrease. It is also not advisable to put washers thicker. In large gaps between the saws, thin branches will get stuck.

The shaft is machined on a lathe. It is necessary to provide threads for nuts for clamping a set of saws and a working pulley. Bearing seats are machined on both ends of the shaft.

For the drive it is better to use an electric motor. If the assembled garden electric shredder with your own hands runs on a 220 volt network, then it will be able to grind only thin branches and green mass. For processing thick branches, a three-phase electric motor is required. As an option, the chopper can be adapted to be connected with a belt to the motor pulley of the walk-behind tractor.

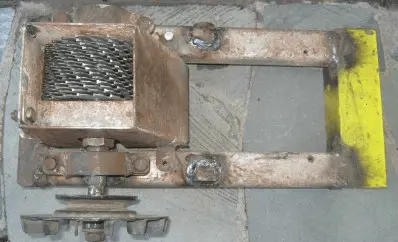

The chopper frame is welded from a steel profile, channel or corner. First, make a rectangular base for the chipper. Here it is important to fix the bearing seats evenly so that there is no distortion, and the axis of the electric motor and the shaft with circular saws must be in parallel planes. Support posts are welded to the finished base for the chipper, which will play the role of the chopper legs.

The shredder hopper is made of sheet steel with a thickness of at least 1 mm. Thin tin should not be taken, as it will be deformed from the blows of flying chips. The height of the bunker is made greater than the length of the arms. This is for personal safety.

A shredder made from a set of saws will cope with any organic matter. However, the chipper will need to be cleaned frequently.

Assembling the chopper with a knife disc

This shredder with knives is only capable of processing soft organic matter. It is more intended for the preparation of green fodder for poultry and animals. The bunker is bent out of tin. You can adapt a galvanized bucket or a housing from old appliances, such as a fan. The bunker will be flexible, but great strength is not needed here. After all, the grass chopper will not thresh branches.

The chipper is made of sheet steel with a thickness of 3–5 mm. 4 slots are cut out on the disk with a grinder. Next, take a piece of an automobile spring, sharpen it and drill 2 holes. 4 pieces of such knives are also made, after which they are inserted into the slots on the disk and fastened with bolts. A hole is drilled in the center of the disk. The threaded end of the shaft is inserted into it, after which it is firmly tightened with a nut. The shaft itself with bearings is attached to the frame, and a pulley is put on the other end.

To cut grass, it is enough to connect the chopper with an electric motor with a power of 1 kW.

Assembling a two-roll chopper

Assembling a two-roll garden shredder begins with a frame. First, a rectangular structure is welded. Inside the frame, four shaft fasteners are welded to the side elements. They are positioned so that the cutting drums are level.

Further, according to the presented scheme, 2 shafts with cutting drums are made. For three knives, you will need to find a round blank. Under 4 knives use a steel square. In any case, the edges of the shafts are sharpened in a round shape for bearings.

Knives are made from car springs. Two mounting holes for bolts are drilled on each element. Each knife is sharpened at an angle of 45о, applied to the shaft and mark the attachment points. Now it remains to drill holes according to the marks, cut the threads and bolt all the knives. The cutting drums are ready.

The next step is to assemble the chipper. To do this, holes are drilled in opposite walls of the steel box. Around them, nests are formed from a steel strip, where bearings are inserted along with shafts. During rotation, the drums should not cling to each other with knives.

Gears are mounted on each shaft. They are needed to synchronize movement. The finished chipper is bolted to four internal elements welded on the frame. The bunker is welded from sheet steel 1–2 mm thick. Belt drive pulleys are put on the shafts of the cutting drum and the engine. You can use a chain drive. Then instead of pulleys put stars.

A two-roll shredder can be powered by a three-phase electric motor or a walk-behind tractor motor. In this case, the power is enough to process branches up to 8 cm thick.

Conclusion

In the manufacture of homemade choppers, craftsmen use grinders, drills, vacuum cleaners and even washing machines. Of course, such shredders will turn out to be weak, but it will be possible to chop grass for bird feed.