Contents

One way to decorate areas is to use forged products. Fences, benches, gazebos, stair railings and other similar structures look very decorative. Moreover, in most cases, these products are not forging in its traditional sense. Most often this is done not in a forge and not with a hammer and anvil, but with the help of some devices that allow you to create a wide variety of patterns and products from metal strips and square bars. For the manufacture of such products, cold forging machines will be required. Some of them can be made with your own hands, others are easier to buy.

What kind of devices are used

Cold forging is characterized by various curls, bends, twisted rods, etc. Almost every type is made on a separate device – a specific machine. The drive they can be manual, or maybe electric. For small volumes “for themselves”, manual cold forging machines are used. Although they are not very productive, they are much easier to manufacture. If it is necessary to put production on stream, similar devices are made, but with electric motors. In this case, it is almost not necessary to work physically, but the complexity of manufacturing the device increases significantly. In our material we will talk about manual machines for cold forging.

What devices are used:

- Torsion. With their help, tetrahedral bars or strips of metal are twisted in the longitudinal direction. It turns out twisted columns, which are also called torsion bars.

It looks like a torsion bar and a machine of the same name - Flashlight. On this device, the bar is also twisted in the longitudinal direction, only it is additionally bent in the transverse direction. It turns out something similar to a flashlight. Hence the name of the device.

This is how a flashlight is made - Twisters or snails. Form flat curls of different diameters.

Device for cold forging snail – for forming curls - Bending machines or benders. Allows you to bend rods or rebar at the required angle in any place.

For bending anywhere and at any angle – bending machines (bending machines) - Wave. In fact, this is also a bend, but of a more complex design – it allows you to change the direction of the bend, getting wavy details.

Machine “Wave” – for the formation of the appropriate relief - Devices for processing the ends of parts – inertial stamping machines or other home-made devices.

Machines for finishing the ends of bars. In this case, goose foot

For a novice craftsman, the most relevant cold forging machine is a snail. Only with its help you can make a lot of interesting things – from a fence and a gate to a bench and other similar products. In second place, according to the degree of need, is a torsion machine. It adds variety to the details. All the rest can be acquired or made as you improve and gain skill.

Homemade “Snails”

In fact, this is a modernized bending machine (pipe bender), but these improvements make it easy to make curls from fairly thick bars (section up to 10-12 mm) and repeat them with a high degree of accuracy.

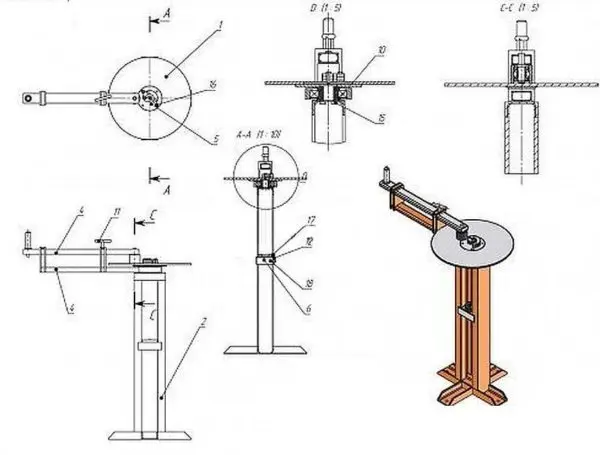

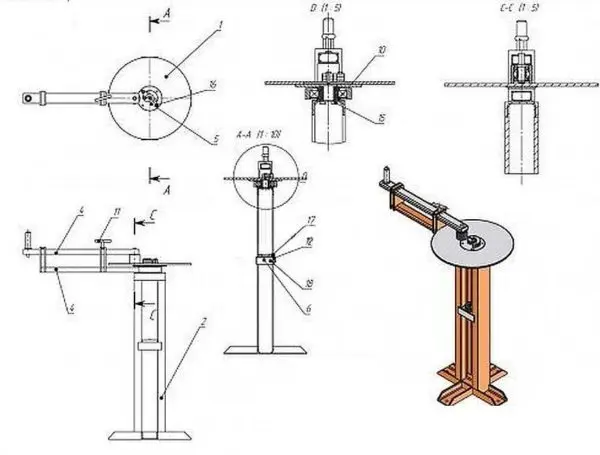

These cold forging machines have several designs, but the easiest option to implement is a round table with a central leg. A lever with rollers on bearings at the end is movably fixed to the leg. They make the bending process easier.

The surface of the table can be made of steel sheet with a thickness of 10 mm or more. For the leg, you can use any thick-walled round pipe. It is important to make the structure stable, as lateral forces will be applied, therefore side racks, struts, as well as a stable base are needed.

The lever is easier to make from a square pipe with a thick wall – at least 2-3 mm. Pipe section 25*40mm or so. The lever can be attached to the leg on a bearing, or you can simply take a small piece of a thick-walled pipe of a larger diameter, put it on the leg, and weld a stop strip from below so that the lever does not fall down. The bearing option gives easier movement, but with lubrication, the second option is also working.

The shape of the lever is also important. The lever is double, the upper part is working, the lower one is supporting. Wherever there are connections, it is desirable to add reinforcement, since the efforts are significant.

A mandrel or jig is fixed on the table – a form along which the curls are bent. They are made in different diameters – so that you can make curls of different diameters. Such mandrels can be prefabricated – to form more bends. Each such sample must have rods that are installed in holes in the table. So this template is fixed. Also, its shape must be designed in such a way that the end of the bar is well fixed in it.

Often, mandrels are machined from a metal circle of a suitable diameter using a grinder, but there are metal options with steel plates welded onto it, curved accordingly.

How to make a similar machine for cold forging – in the next video. There is also a good description of how to bring the ends of the workpiece to a decent state – the usual raw edges look very rough. There is special equipment for processing them, but, as it turned out, you can cope without it.

Torsion machine

As already mentioned, these cold forging machines allow you to make longitudinal bends on the bar. This is a relatively simple design. The main task is to fix one end of the bar motionless, to attach a lever to the second, with which it will be possible to twist the workpiece.

As a basis, a cut of a profiled pipe with a thick wall (at least 3 mm) is suitable. The latch can be welded from the same rods, leaving a square gap of the desired diameter. You can use a cable clamp of a suitable size (can be found at a rigging store). Any of these stops is welded to the base.

Next, you need to somehow ensure the capture and torsion of the second part of the workpiece. This can be done using two bearing assemblies. A pipe of a suitable diameter is inserted inside, on one side a handle is welded to it – the design resembles the letter “T”. On the other hand, a retainer is made in the pipe: four holes are drilled, nuts are welded into them for 12 or 14 bolts. The result is a good latch – the bolts are tightened after the bar has been inserted.

Further – a matter of technology – we wind the required number of turns with a lever. This is not to say that this job is for wimps, but with a lot of leverage, everything is not so difficult.

An even simpler machine for making torsion bars by cold forging is in the next video.