Contents

Feeders for bees are easier to buy in the store. They are inexpensive. However, many beekeepers are accustomed to making primitive containers themselves in the old fashioned way. In addition, such an experience will not hurt if the apiary is far away in the field. When there is no store nearby, and feeders are urgently needed, ingenuity comes to the rescue.

Do bees need feeders?

Mandatory feeding of bees is carried out at least 2 times a year. The first time – in early spring before the flowers bloom. The second top dressing is carried out in the fall. The procedure is aimed at replenishing food supplies for the winter. There are additional top dressings with sugar syrup when it is necessary to replace poor-quality honey or reduce the cost of winter food. Feeders were invented to organize the nutrition of bee colonies.

Types of bee feeders

There are many varieties of factory and homemade bee feeders, but they are all divided into 2 types, depending on the installation location:

- external;

- internal.

In turn, external devices are:

- Mounted. Devices are made in the form of a box and are usually fixed on the hives or in the vicinity. Plus – ease of maintenance. Minus – food is stolen by wasps and other bee colonies.

- Terms. The feeder is a large container with sugar syrup. It is installed near the apiary. Twigs or a wooden bridge float on top of the syrup in the container so that the insects do not drown. Plus – ease of design and maintenance. Minus – bees from different families receive food unevenly.

There are many more varieties of internal feeders:

- Framework. Devices are made in the form of containers according to the size of the frame. Fasten the box near the nest. Plus – it is convenient to feed bee colonies in rainy weather. Minus – to add food, you need to disturb insects.

- Disposable polyethylene. The feeder is an ordinary bag filled with syrup and tied with a knot on top. They are placed at the bottom of the hive or on top of the frames. Instead of syrup, medicinal solutions for the treatment of bees can be poured into the bag. Plus – simplicity, low cost, availability in the field. Minus – the rapid cooling of the poured solution.

- Ceiling. Among beekeepers, at least two variants of such feeders are common. Plastic models are good to wash, it is convenient to place in the hive, but insects sometimes get inside the glass and die. Box-type feeders are beneficial in large apiaries. Designs allow you to feed bee colonies for a long time without opening the hives to add food.

- Bottle. Feeders are made from PET bottles. By location, they are vertical, standing at the bottom of the hive or horizontal, suspended with fastening bars.

Any container can act as an internal feeder. They use glass and tin cans, make foam models and other devices.

What material can be used to make feeders

If you look at the photo of bee feeders, you can see the inexhaustible fantasy of beekeepers. Containers are most often made of wood, glass, polystyrene. A popular material is polyethylene and other types of plastic, but the polymer is used only for food products. If the product emits toxic odors, the quality of honey will deteriorate or bee colonies will die.

Intrahive feeder for bees

From the name it is clear that any feeder installed inside the hive is called intra-hive. According to the location, the structure can be ceiling, floor or side. The first two types include products from bottles, bags, boxes. Depending on the model, they are placed on the bottom of the hive or suspended from the ceiling. The side feeder is placed next to the combs.

How to make a bee feeder with your own hands

The most efficient intra-hive feeder is considered to be the side model. It is made in the form of a plywood flat box. The syrup is poured through the top funnel. Be sure to equip a floating bridge that prevents the bees from drowning. The top of the box is equipped with two mounting protrusions for fixing on the side of the socket.

You can take a closer look at the assembly of the intra-hive feeder on the video:

Frame feeder for bees

The most common side feeder in the manufacture is the frame model. The dimensions of the container are identical to the frame with honeycombs. The product is similarly made in the form of a box with an open top for pouring syrup. A floating bridge is arranged inside, preventing the bees from drowning. A self-assembled frame feeder for bees is installed instead of a frame on the side of the nest, hung to the wall with hooks.

How to make a bee feeder

It is easy to build a frame device for feeding bees. An ordinary frame is freed from honeycombs and wire. The sides are sheathed with plywood. It is important to securely seal the joints to prevent leakage of the syrup. You can use wax. The upper jumper of the frame is removed to make a container. A floating bridge is being built here. A lid is cut out of a piece of plywood, a hole is drilled. The device will limit the mass contact of bees with food. In addition, a funnel is used to add syrup through a watering can.

Vertical feeder for bees

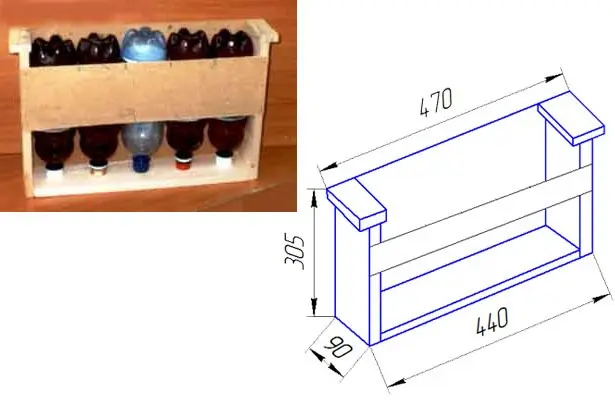

A battery of PET bottles can act as a vertical feeder. The box-type design is a cassette made of plywood or thin boards, inside which containers with syrup for bees are installed vertically with their neck down.

Manufacturing process

The photo shows do-it-yourself drawings of a feeder for bees, but you need to calculate your own dimensions according to the dimensions of the hive. First, 4-5 identical bottles are selected, their diameter is measured. According to the measurements taken, the thickness of the cassette is determined. The boxes are assembled from plywood or thin planks.

With an awl or a nail, holes are pierced along the ring of the bottle, stepping back from the bottom 1 cm. They are needed to supply air to the container so that the liquid does not hang. Inside the cork there is a sealing insert. It is removed. The bottles are filled with syrup, loosely corked with corks without seals, turned upside down and placed inside the box. The cassette is placed inside the hive on the side of the bee nest.

Ceiling bee feeder

A universal ceiling feeder is considered a box-type model. The structure is fixed in folds or installed on a shelf, where a hole is pre-drilled so that the bees can get to the food. The box is made of such length that it enters between the back and front walls of the hive. Divide the capacity for bees into 3 sections:

- filling chamber for syrup;

- feed compartment with a floating bridge for bees made of plywood or foam;

- a small compartment for the passage of bees into the feed compartment.

A separating partition is placed inside the aft compartment, which does not reach the bottom by about 3 mm. In the third compartment, the partition does not reach the top by 8 mm. There is no bottom at the bottom, due to which a gap is formed for the access of bees to the feeding compartment.

Manufacturing process

When assembling a ceiling feeder for bees with their own hands, they first knock down the box. Grooves are cut in the upper part of the sidewalls. The pouring chamber for syrup is covered with a fiberboard blank. The two remaining compartments are equipped with a common glass cover. Through the transparent surface it is convenient to observe the bees. To avoid the flow of syrup, the joints of the box are put on PVA glue, tightened with self-tapping screws. Outside, the seams are additionally sealed with wax.

Feeder for bees from a plastic bottle

The advantage of the simplest device is the economic benefit. Empty PET bottles can be collected for free. After feeding the bees, they are simply thrown away, which eliminates the extra work of washing and disinfecting. The disadvantage of the device is the rapid cooling of the syrup in bottles. Feeders are used most often in hives with a low roof.

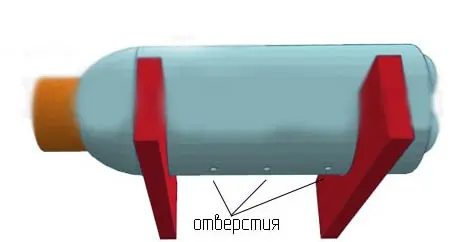

Traditionally, do-it-yourself feeders for bees are made from a plastic bottle of two types: horizontal and vertical. For manufacturing, you will need containers of 1,5-2 liters, an awl, adhesive tape, a jigsaw.

Manufacturing process

To make a horizontal model, a straight line is drawn with a marker on the side wall of the bottle from the neck to the bottom. By marking with an awl, up to 7 holes are pierced at an equal distance.

2 holders with recesses for a bottle are cut out of bars or pieces of chipboard. The elements are attached to the wall of the hive. The side holes on the bottle are sealed with tape. The container is filled with syrup, corked. The adhesive tape is sharply torn off, the bottle is placed on the holders with holes down. The flow rate of the syrup will depend on its viscosity and the diameter of the holes.

For the vertical model, the bottle is prepared exactly as the cassette design was made. Holes are pierced near the bottom, sealed with tape. The container is filled with syrup. The seal is removed from the cork, the neck is loosely clogged. The bottle is turned over, the tape is torn off. As a stand, a bar with a hole cut out along the diameter of the cork is used. You can saw through the groove along which the syrup will flow. Additionally, a vertically installed bottle inside the hive is fastened with a clamp to the wall.

What else can you make bee feeders from?

In fact, bees can be fed from any container and even a PET bag can be used. Each device has its pros and cons, but helps out in the field.

From packages

A disposable feeder is good because it does not need to be disinfected, as there is no need to reuse it for bees. Packages are cheap, but differ in strength and size. They are selected according to the type of feeding.

If the bees require stimulating feeding, a small amount of the sweet mixture (up to 1 liter) is poured into small thin-walled bags. For winter replenishment of stocks for bees, it is optimal to use large thick-walled bags containing 3-4 liters of syrup.

During feeding, the bag is filled with a sweet mixture, excess air is released, tied in a knot above the feed by a third. In an air-free space, the syrup will spread when the bag is flattened on top of the frames. At the request of the beekeeper, the feeder can be placed behind the bar inside the hive.

For stimulating feeding, the bags are placed on the frames whole. The bees gnaw through them. In a large bag for a full replenishment of food, a couple of holes are punched on the side and one on top for baiting bees. When all the syrup is drunk, the old bags are thrown away, and a new portion of feeding is placed in the hive.

From cans

If there is an empty body installed above the frames in the hive, the bee feeder is placed from a glass jar. You will need dense gauze, folded in eight layers. It is soaked with clean water, squeezed well. The jar is filled with syrup. The neck is covered with gauze, tied with a rope or elastic band. The jar is turned upside down, put on top of the frame.

The simplest bee feeder is shown in the video:

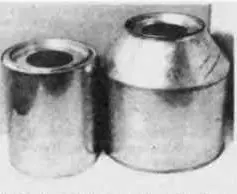

From tin cans

Glass containers can be successfully replaced by tin cans. The principle of making a feeder is the same. You will need the same gauze in 8 layers. Sometimes tin cans come with nylon lids. They can be used instead of gauze, piercing many small holes with an awl.

A jar of syrup is turned upside down, put on a frame. For better access of the bees to the food, thin sticks are placed under the container.

From foam plastic

Foam feeders are sold factory-made. A similar ceiling model can be glued from foam sheet. However, there is an easier option. For homemade, a conical PVC container with a diameter of about 200 mm, a piece of chintz fabric, an elastic band, and a foam plate 30 mm thick are required.

A circle is cut out of the foam board with a sharp knife. In diameter, it should fit tightly into the neck of the cone-shaped container. A hole 7 mm thick is pierced in the center of the foam disk, and grooves are cut from the outside of it. On the sides of the disk, 4 more grooves are cut with a depth of 5 mm. Syrup is poured inside the cone. The container is covered with a foam disc. The chintz fabric is stretched from above and the cone is turned over. If the syrup flows quickly through the fabric, add 1-2 more layers until even distribution begins. The feeder is fixed inside the hive with grooves cut on the side of the foam disk.

What are the best bee feeders?

It is impossible to determine the best feeder exactly. A certain type of model is selected, depending on the amount and time of feed supply, the design of the hive, the frequency of the beekeeper’s appearance on his farm.

It is considered the best feeder that meets all the requirements:

- bees get access to food in any weather;

- the design is easy to clean, disinfect or disposable;

- bees should not get wet and die in a sweet liquid;

- the feeder should not attract wasps and other bees;

- minimum contact of the serving person with the bees during loading of the feed is desirable;

- The beekeeper must see the amount of uneaten food.

Taking into account the listed requirements, the beekeeper himself determines the optimally suitable option.

Conclusion

A good beekeeper always has feeders for bees at the ready: serviceable, clean, disinfected. When urgently needed, they can be used immediately.