Contents

For children, parents always try to choose the best, including furniture, but looking at completely unchildish prices for wooden beds, or for beds – cars, boats, etc. involuntarily you will think about whether it is worth buying such a thing for several years … Maybe not to buy, but you can do it yourself. A do-it-yourself baby bed can be assembled from several boards and bars in a few days. Particularly complex work or special tools are not required. Basically, you need hands and desire.

wooden bed

This is an ordinary bed without any tricks. In the presented version, it is suitable for middle school age and adolescents, but then it can be completed for children from 3 years old (second photo report). It is assembled from wooden parts (boards and bars). The project can be used as a basis, then adding design ideas.

Materials and Tools

No special tools are required for manufacturing. All that is needed:

- a saw (hand-held for wood or a circular saw – whoever has something, maybe – a face saw, you can cut it with a grinder with a disk for wood);

- Desktop;

- drill with drills and countersink;

- grinder (if not, you can work with sandpaper manually);

- roulette.

Tools you need to get the job done

The materials needed are:

- timber – 50 * 100 mm;

- board 25*100 mm and 25*75 mm;

- glue for wood;

- putty for wood;

- sandpaper.

The number of boards-bars is considered based on the planned dimensions. Requirements for wood – low humidity (not higher than 16%) and the absence of knots or their small number.

Children love to sleep higher. How to make a loft bed read here.

Making legs

A do-it-yourself baby bed begins with the manufacture of legs. From a bar of 50 * 100 mm we cut blanks – for the headboard it is longer, for the footboard it is shorter. You need 4 of each length. We glue the blanks in pairs. We take one, coat it with wood glue, lay the second one, checking whether they are evenly set, twist them with self-tapping screws. In principle, you can use a beam of 100 * 100 mm and do not mess with glue, but the price of it bites very much.

The heads of the screws are sunk into the wood, then sealed with wood putty. After drying, grind to a smooth state (sandpaper with medium or fine grain).

We also use sandpaper to bring the junction to an ideal state – everything should be even and smooth.

Dowel holes

For the backs, you will need boards with a groove of 25 mm wide. If there is a milling cutter, you can make it yourself or grind it in a carpentry shop. Dowels can also be bought ready-made, choose a drill according to their diameter.

Holes for dowels are drilled at the ends of the planks with grooves. Accurately determine their distance from the edge – they must be strictly on the same level on all planks.

Also, the holes should be the same depth – half the length of this piece of wood. In order to be able to navigate when drilling, a marker is attached to the drill – a strip of masking tape. It controls the depth of the hole.

Assemblage of a headboard and footboard

Planks of the same length are cut from a board of 25 * 50 mm to fill the head and foot. They are inserted into the groove, smeared with glue in advance.

We also drill a hole for the dowels in the leg. First we find the middle, draw a line along it (with a pencil). Attach the assembled backrest, align it along the upper edge, put the dowels on the line and mark the places where you need to drill holes for them (two at the top, two at the bottom). Pour a little glue into the holes and put the back. It should be planted tightly, without cracks. You can knock with a fist or a mallet (do not damage the wood).

We repeat the same operation with the other leg. A not very beautiful joint at the top can be closed with a board, putting it on self-tapping screws and covering the holes. As a result, here’s what happens.

One important point that concerns gluing parts. Until the glue has hardened, the joints are movable and the parts may warp. Therefore, setting the angles to 90 °, the part is fixed (with clamps or in some other way) and left until the glue dries. Work is continued after drying, and, as a rule, it begins with grinding the joint, which has just been glued.

How to make a sports corner for children, read here.

Making the base for the mattress

We take two boards 50 * 100 mm long, equal to the length of the mattress (or a couple of centimeters more to make it more convenient to refuel). Along the edge, we put a 25 * 50 mm bar on the glue and self-tapping screws. It is 10 cm shorter in length – we leave 5 cm from each edge. When screwing the bar, make sure that the edges are set exactly. We drill a hole under each self-tapping screw – close to the edge so that the wood does not burst. In addition, we make a hole of a larger diameter along the hat – they should be hidden.

Since the adhesive joint in this case is fastened rigidly, you can not wait until the glue dries.

From the board 25 * 100 mm we cut the planks along the width of the mattress (you can add 1-2 cm again). They are attached to the just-made planks with an emphasis. Installation step – 10 cm, for each bar – 2 self-tapping screws on each side. A hole is pre-drilled under each self-tapping screw (the diameter of the drill is 1-2 cm less than the diameter of the self-tapping screw), the cap should go into the wood.

Holes for fasteners are covered with putty, polished after drying. In the extreme slats, cutouts are made for the installation of legs.

DIY baby bed: assembly

We finally close up all the chips and defects on the visible parts of the bed with putty, after it dries, we grind it to smoothness. Then primed and painted in the chosen color. After painting, it remains only to connect the backs and the base under the mattress, and we can assume that the children’s bed is ready with their own hands.

You can connect the parts with the help of special fittings – brackets and curtains, or in a simple way – by nailing a corner, a bar, on which to rest the assembled shield for the mattress.

How to make a two-story children’s bed, read here (there is a photo report).

Homemade car bed

Few boys will refuse a car bed. And to please the child it is not necessary to go to the store. With the help of plywood or MDF sheet, paints and water-based varnish, an ordinary sleeping place turns into a dream come true: a do-it-yourself children’s bed in the form of a Batmobile (or any other car) is realized in a week of leisurely work in the evenings.

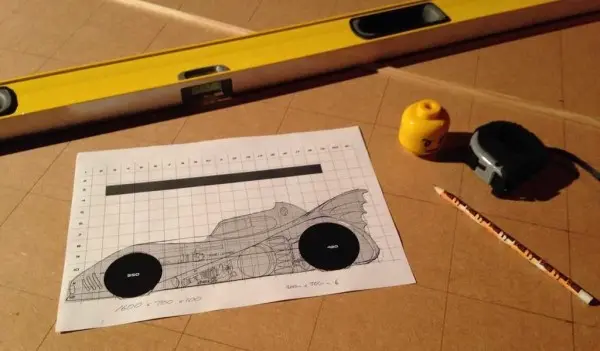

First, find an image of the car that suits you, find a program with the ability to visualize drawings. After transferring the image, it can be divided into squares with a side of 100 mm – so that later it would be easier to translate into a real scale. It’s most convenient if the whole part fits into the plywood or MDF sheet you bought, it’s even better if you can make two sidewalls from one sheet … In general, select the dimensions, change the outlines. After the result suits you, you can transfer the design to the sheet.

It all starts with drawing the sheet into squares with a side of 100 mm.

Referring to the existing sheet, transfer all lines from paper to plywood. At first, the lines are thin, after you have more or less drawn everything, you can outline the resulting contours with a bold line – it will be easier to cut. Although the details are needed in duplicate, it makes no sense to draw the second one: having cut out the first one, we circle it and get the second one.

In this project, there are also overhead parts – we draw them separately. When everything is ready, take a jigsaw and cut along the contours.

The edges turned out to be far from ideal, so we grind them well with a machine or by hand. Then we proceed to sawing grooves, holes, etc. The technique is traditional – we use a drill, drilling one hole near the other, then we file the jumpers. We grind the uneven edge in any way possible, rounding it, and everything should be even and smooth both outside and inside.

After working through all the details, this is what happened.

Read about making a playhouse in an apartment or house here. How to build a house for children in the country or near the house is described here (with photo reports)

Priming and painting

For painting it is necessary to choose safe materials. Best of all – water-based latex, and to protect the paint from scratches and abrasion, a water-based varnish is suitable.

If the parts are made of MDF, it is highly desirable to prime everything, and preferably twice. This material can absorb paint very strongly, especially at the ends. The primer significantly reduces absorbency, and the paint also lays down in a more even layer.

After the primer was dry, the areas that should be gray were first painted over. By design, there are also thin gray stripes. In order not to draw them on black, a thin strip of masking tape (3 mm) was glued on faith paint, removing which then we get the required drawing.

Assembling the car bed

We take one sidewall, fasten a wooden plank of 25 * 25 mm minimum to it with self-tapping screws. We install self-tapping screws after 20-30 cm. We fasten a limiter board to the end of the plank in front. We repeat the same operation on the second part (be sure to fasten the planks at the same height).

Having installed the second part, we twist the structure. In the middle, you need to install a persistent bar that will firmly hold both sides and prevent them from moving apart.

On the planks attached to the sides, like on a frame, chopped planks are laid, which serve as a support under the mattress. They can be fixed with self-tapping screws (two on each side), or you can simply lay them down. In this case, the bed will quickly disassemble. In this option, the second method was chosen – the slats were not fixed, a mattress was laid on them.

Based on the same design, a bed for a girl was made. The shape of the railing is simpler, there is less work with them, but it is more difficult to paint. So, too, their moments.

How to make a playhouse for an apartment, read here.